Cold-work die facilitating heat dissipation

A technology of cold-working molds and concave molds, applied in the field of machining, can solve the problems of large mold damage, increase the frequency of mold clamping, and increase the temperature of the mold surface, so as to reduce maintenance and repair costs, improve service life, and increase impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

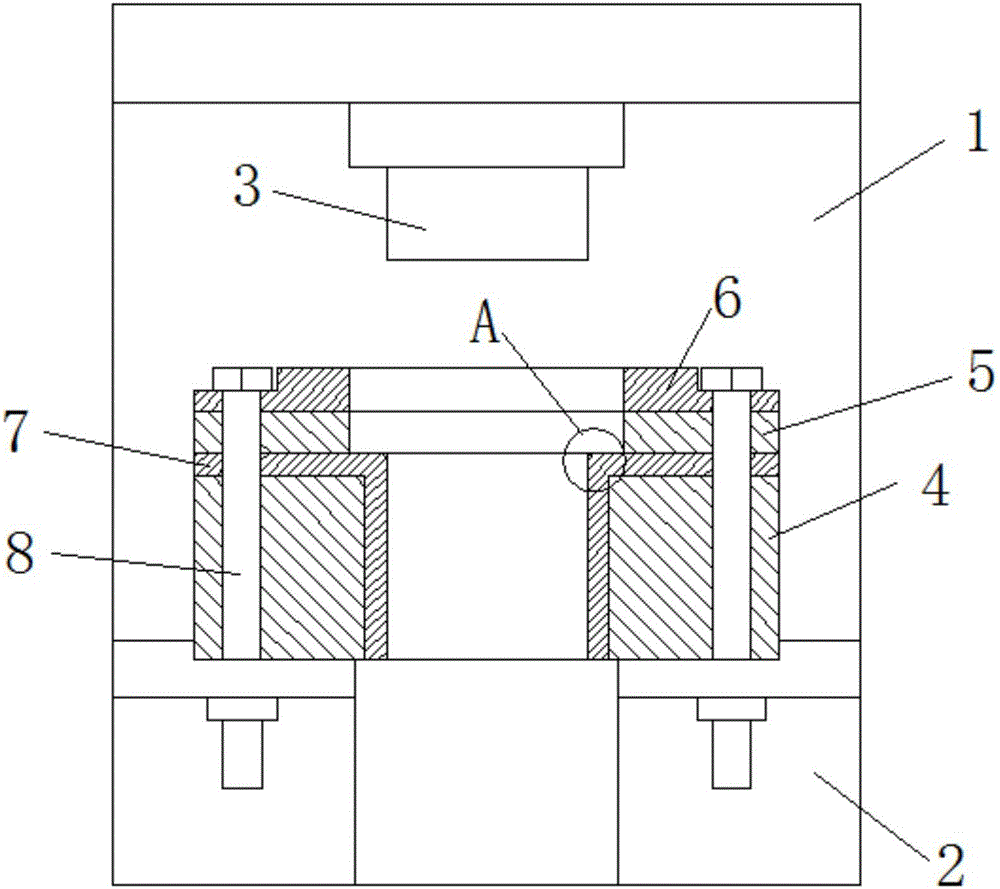

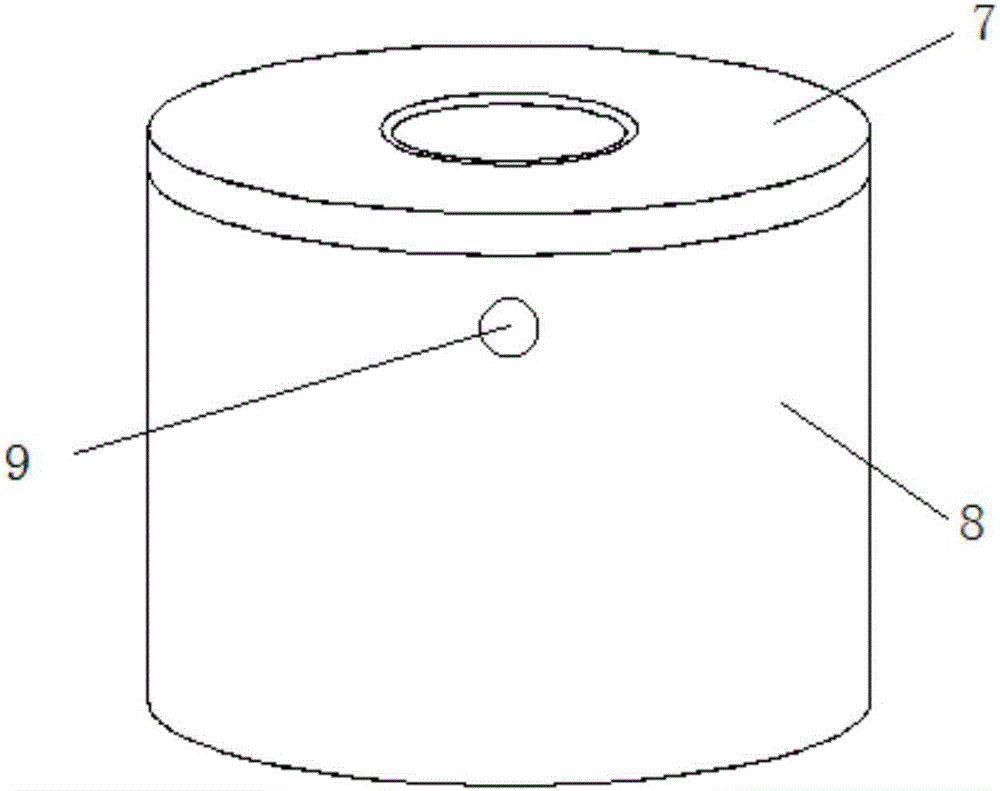

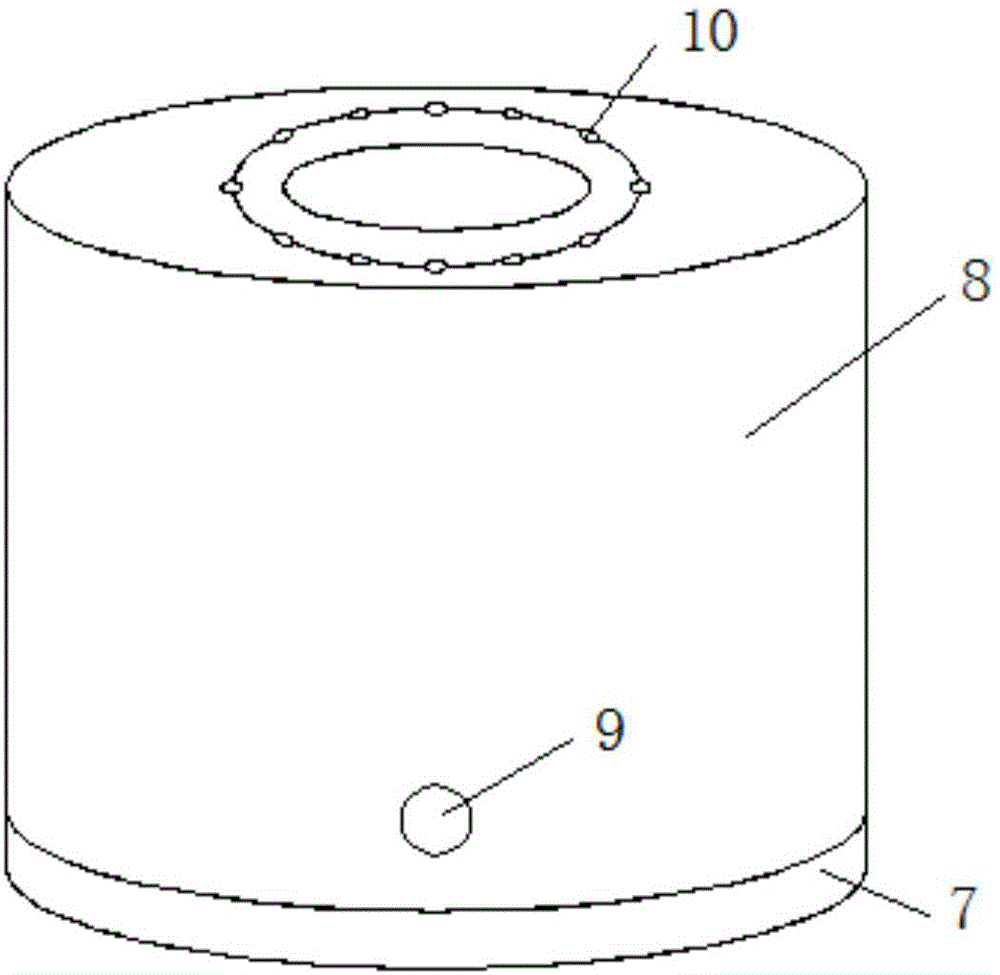

[0019] Such as Figure 1-5 As shown, a kind of cold work mold that is easy to dissipate heat comprises frame 1, workbench 2, punch 3 and die 7, is characterized in that: described frame 1 is fixed on the workbench 2, and described punch 3 Fixed on the lifting device above the frame 1, the die 7 has a T-shaped sleeve structure, and the die 7 is externally sleeved with a heat dissipation collar 4, and the upper surface of the heat dissipation collar 4 is sequentially arranged from bottom to top A positioning plate 5 and a guide ring 6 are provided, and the guide ring 6, the positioning plate 5, the die 7 and the heat dissipation collar 4 are connected and fixed on the workbench 2 through connecting studs 8, and the die 7 The opening at the center of the upper surface is provided with rounded corners 14 .

[0020] In this embodiment, one side of the heat dissipation collar 4 is provided with an air inlet 9, and the connection between the heat dissipation collar 4 and the end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com