A static disc precision forming die structure for new energy vehicle air-conditioning compressors

A technology for air-conditioning compressors and new energy vehicles, applied to forging/pressing/hammering machinery, wheels, manufacturing tools, etc., can solve the problem that the height of the end surface of the scroll-shaped protrusion 24 cannot be guaranteed, and it is difficult to ensure the height of the outer ring protrusion 22 Consistent, inconsistent metal flow velocity, etc., to avoid damage to the metal fiber streamline, avoid cracking defects, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

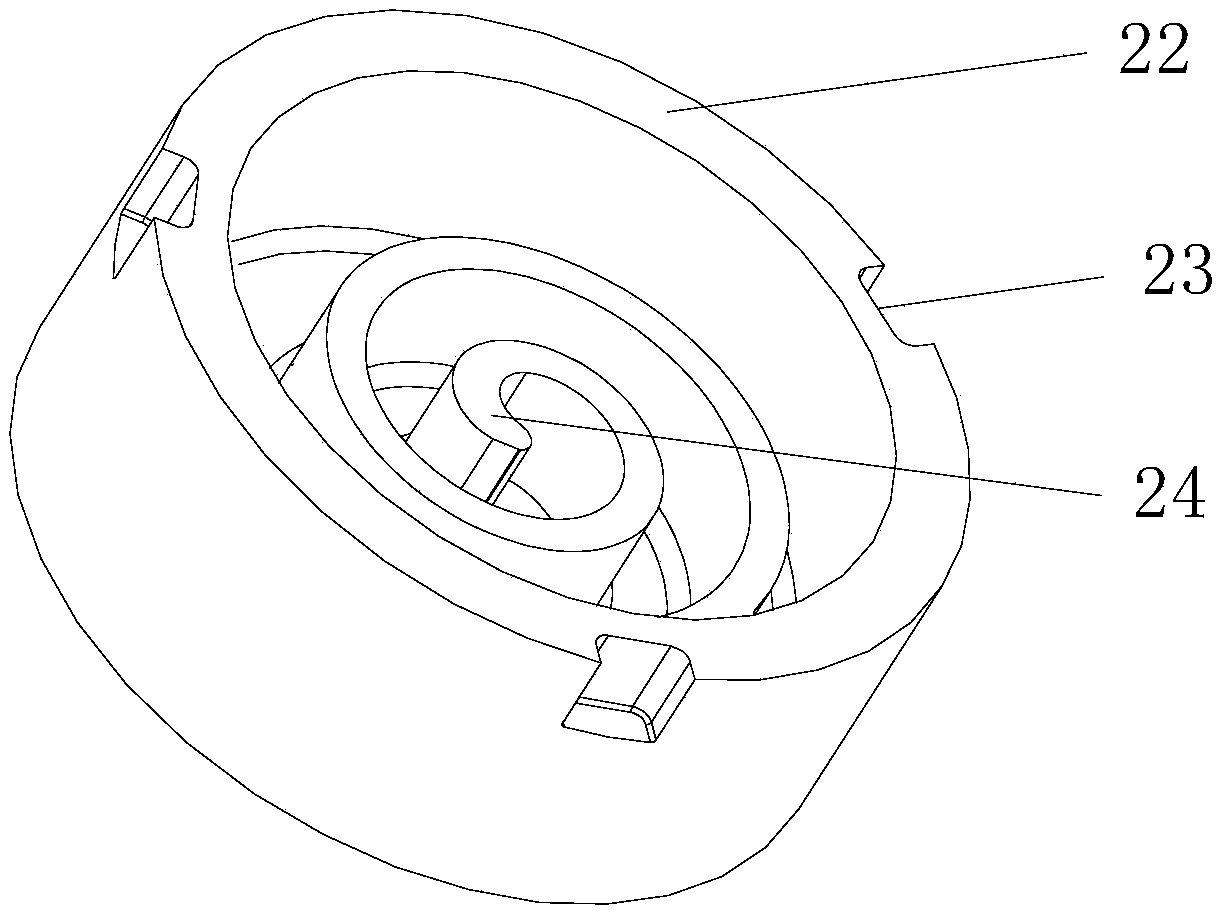

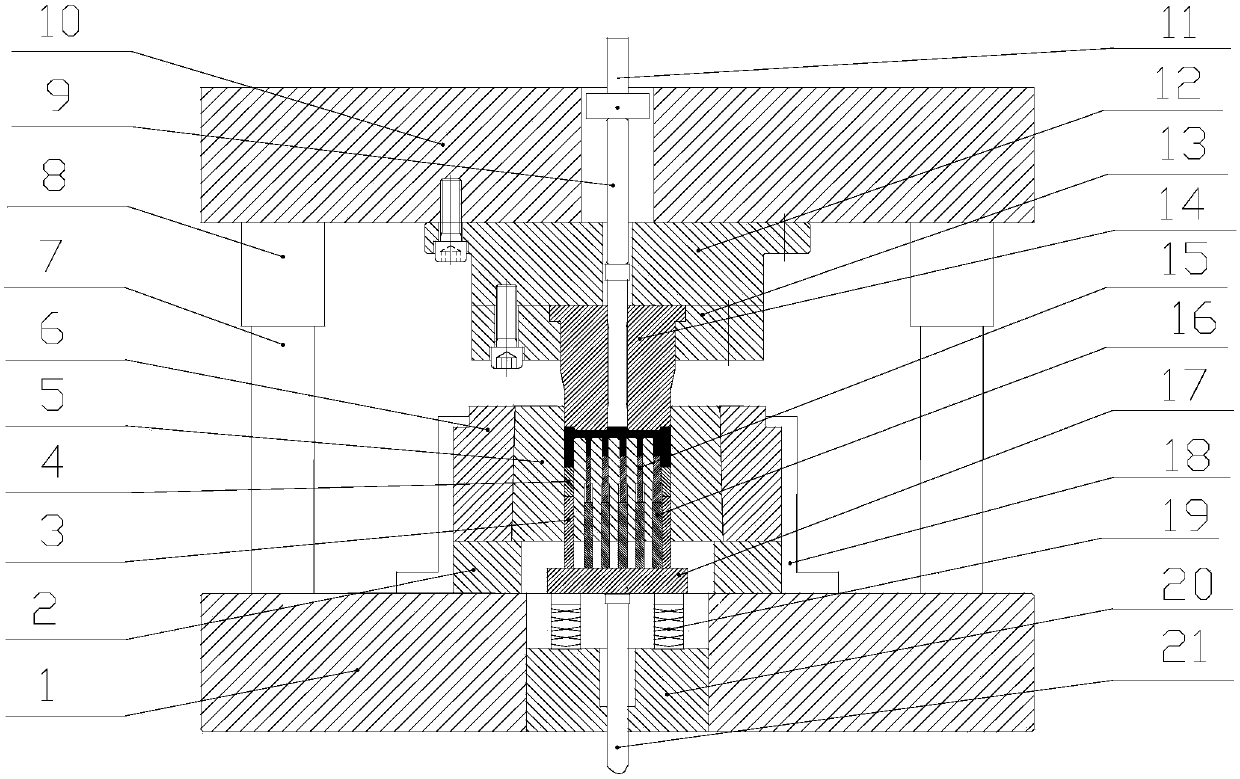

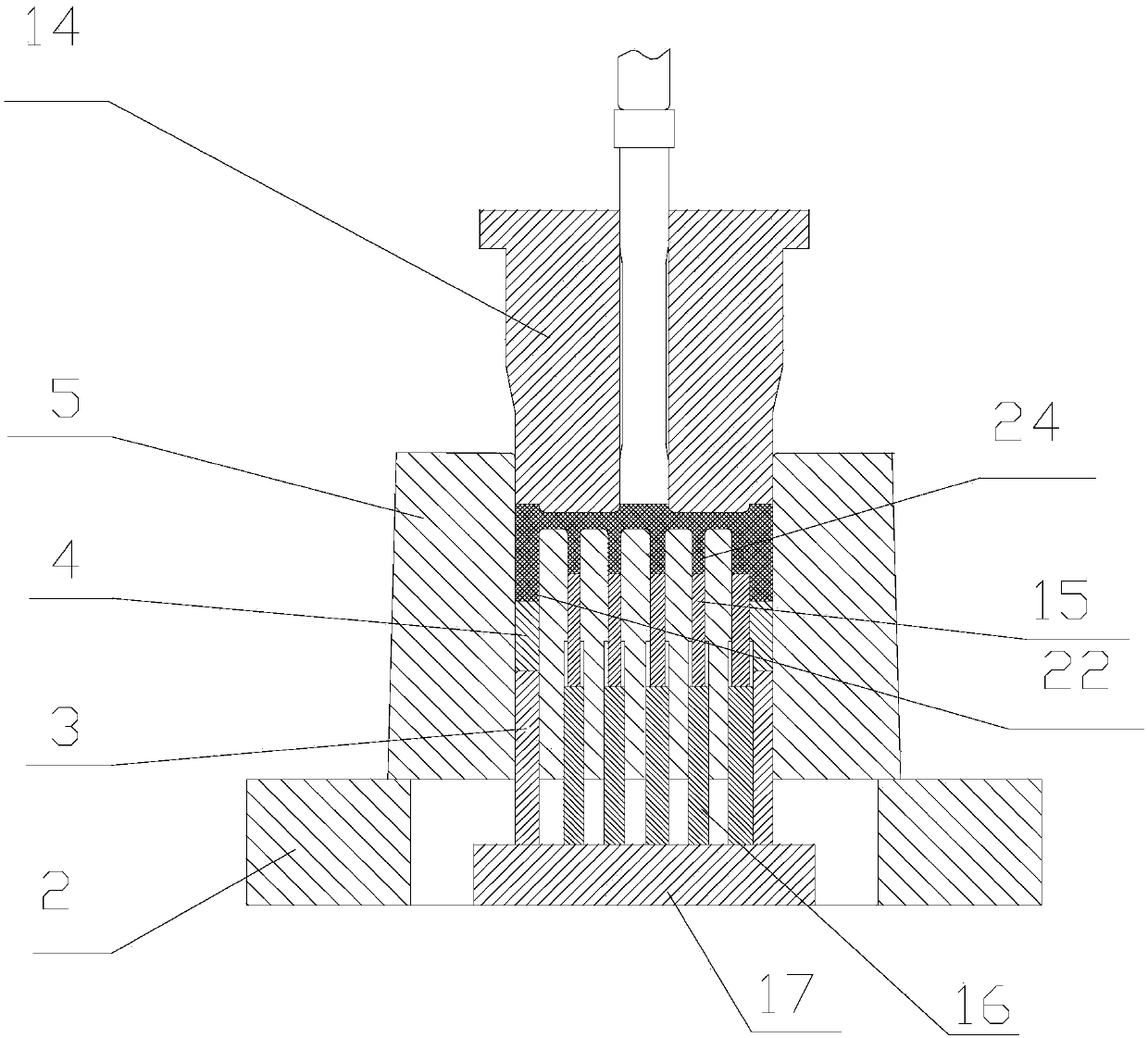

[0022] see Figure 1 to Figure 3 , this embodiment discloses a static disc precision forming mold structure for new energy automobile air-conditioning compressors, the outer ring of the front of the static disc is provided with an annular outer ring protrusion 22, and the middle of the front of the static disc is provided with a scroll-shaped Protrusion 24, the height of the spiral protrusion 24 is lower than the height of the outer ring protrusion 22, the mold structure includes the punch 14 and the die 5, the mold structure also includes a back pressure structure, the back pressure structure includes a scroll bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com