Machining Aids for Turning Slender Shafts

A slender shaft and auxiliary tool technology, applied in turning equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of front-end clamping vibration, large amount of swing, affecting processing accuracy, etc., to avoid vibration and ensure consistent length. performance, ensuring the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The processing aid for turning slender shafts of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

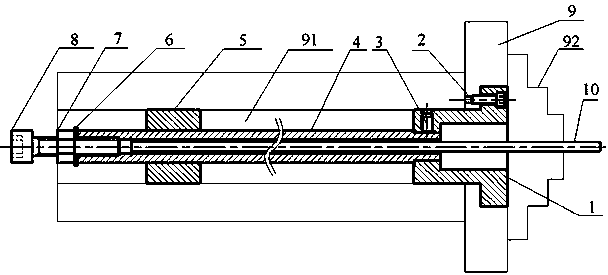

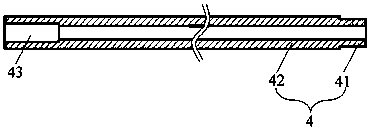

[0026] Such as figure 1 As shown, a processing aid for turning a slender shaft includes a connecting flange 1 fixed to the spindle chuck 9 through connecting bolts 2; one end of the limit tube 4 is assembled into the assembly inner hole 13 of the connecting flange 1, and Fasten by locking the top screw 3; the other end of the limit tube 4 is provided with an adjusting bolt 8, a lock nut 7 and a gasket 6 in sequence; the outer circle of the limit tube 4 is equipped with an auxiliary support body 5.

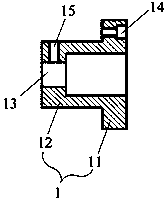

[0027] Such as figure 2 As shown, the connecting flange 1 is a stepped shaft structure formed by a flange 11 and a neck 12, and a stepped through hole is formed in the middle, and the small diameter section of the stepped through hole is an assembly inner hole 13, and the assembly inner hole 13 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com