Non-dry oil seal capable of being oiled rapidly and stably

A non-drying and stable technology, applied in printing, stamping and other directions, it can solve the problems that affect the whereabouts of the internal storage ink, block the oil hole, affect the stamping effect, etc., and achieve fast and stable addition of ink, prevent blockage, and use stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

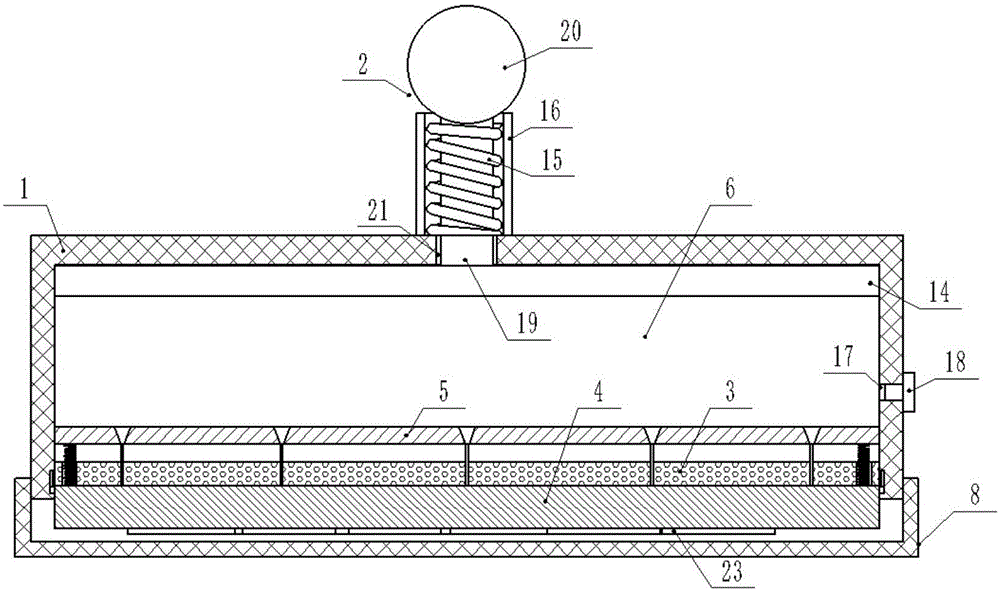

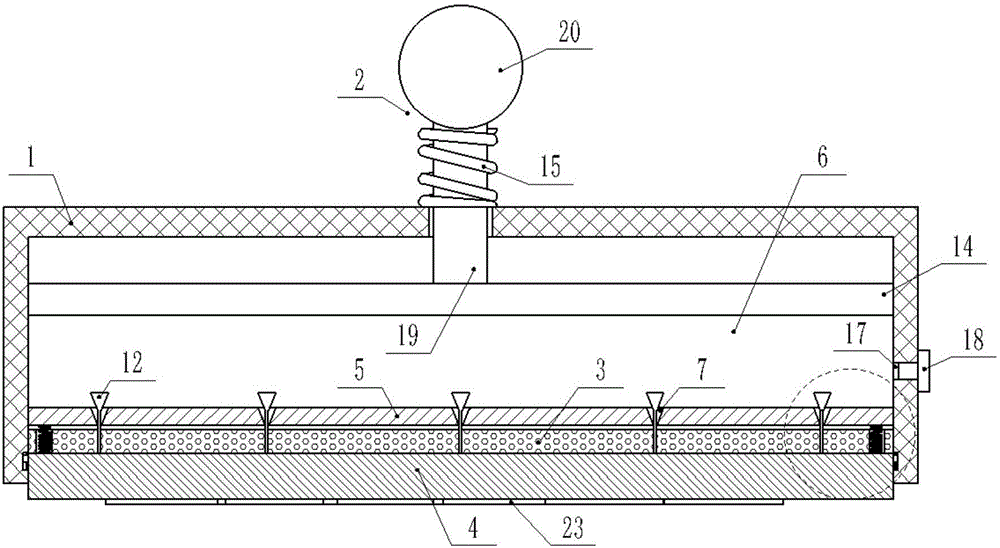

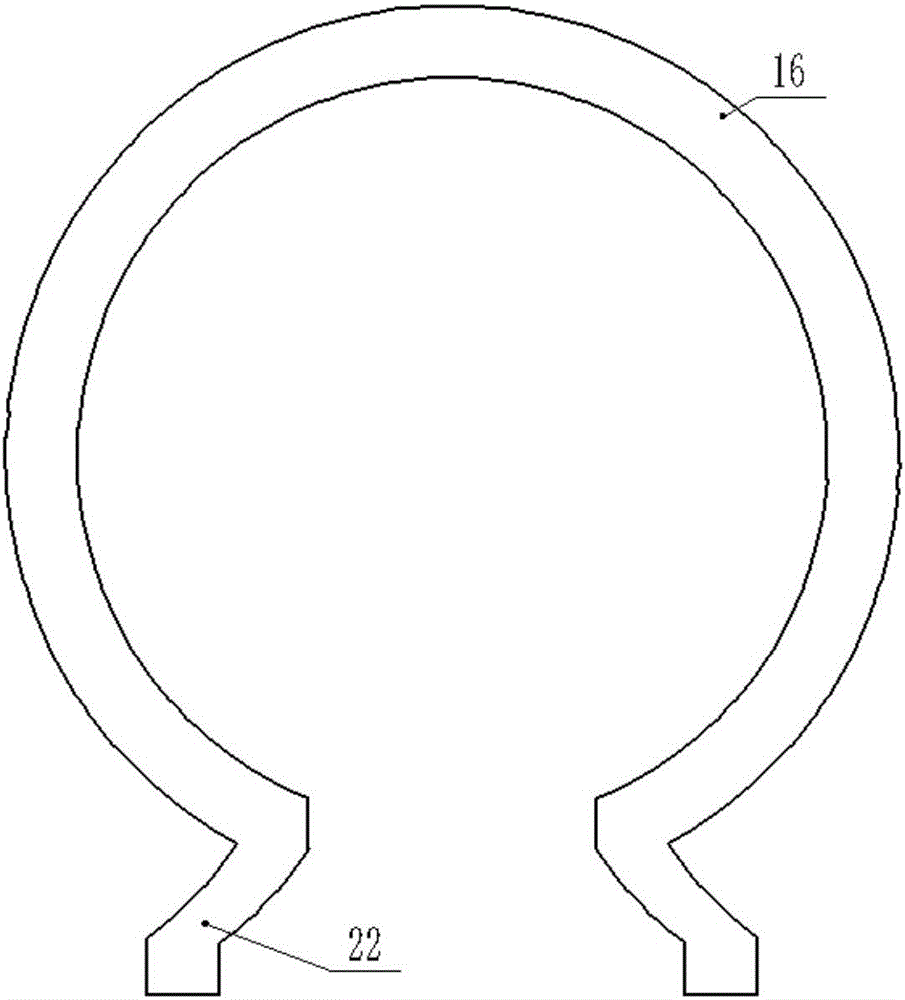

[0016] see Figure 1-4 , a fast and stable non-drying oil seal, comprising a chapter case 1, a chapter handle 2, a sponge body 3 and a seal face 4, the sponge body 3 is fixedly connected to the upper end of the seal face 4, and the seal face 4 is arranged at the inner lower part of the seal case 1, The lower end of the printing surface 4 is provided with a font 23, and an oil passage plate 5 is fixedly connected to the top of the printing surface 4 in the seal case 1. The oil passage plate divides the inside of the chapter case 1 into an oil storage chamber 6 and a stamping chamber. The oil passage plate 5 is provided with a A number of oil holes 7, the lower end of the chapter case 1 is clamped with a chapter cover 8, and the materials of the chapter case 1, the chapter handle 2 and the chapter cover 8 are all ABS plastics commonly used today. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com