Intelligent box type loading trolley

A technology of smart boxes and trolleys, applied in the direction of conveyor objects, conveyor control devices, conveyors, etc., to achieve the effect of fast speed and heavy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

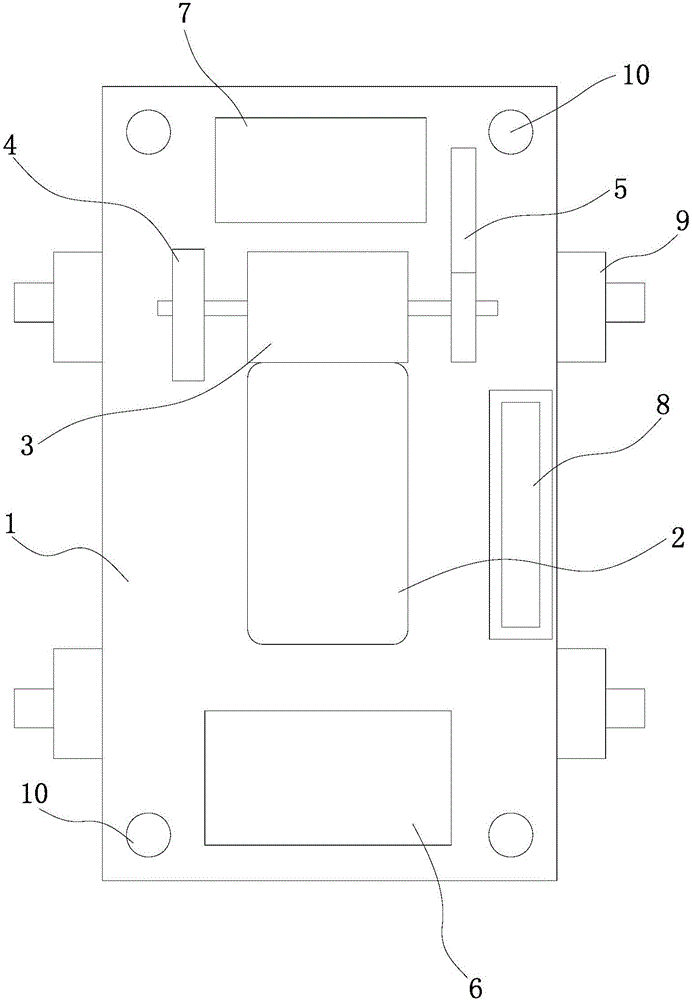

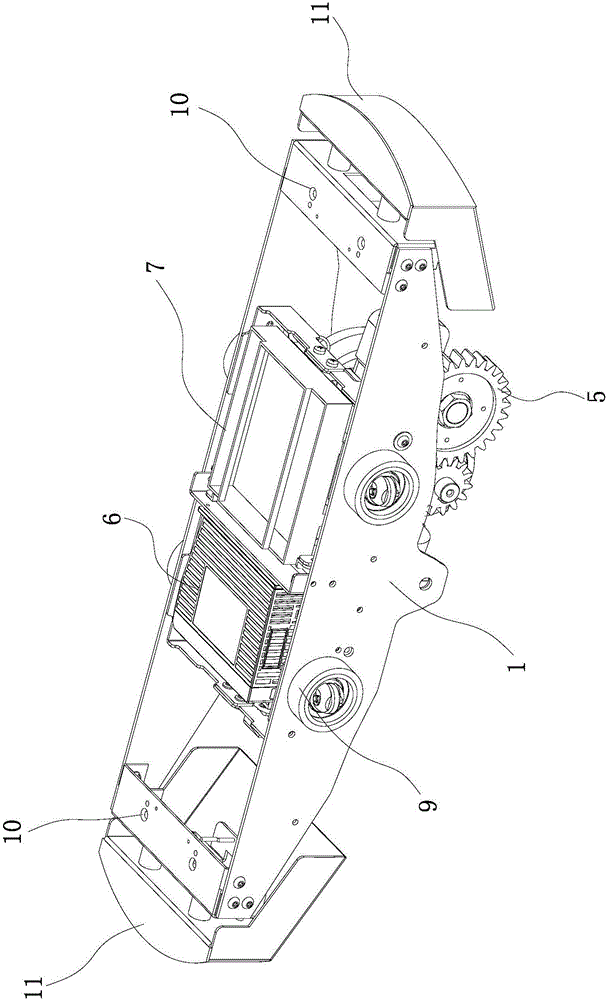

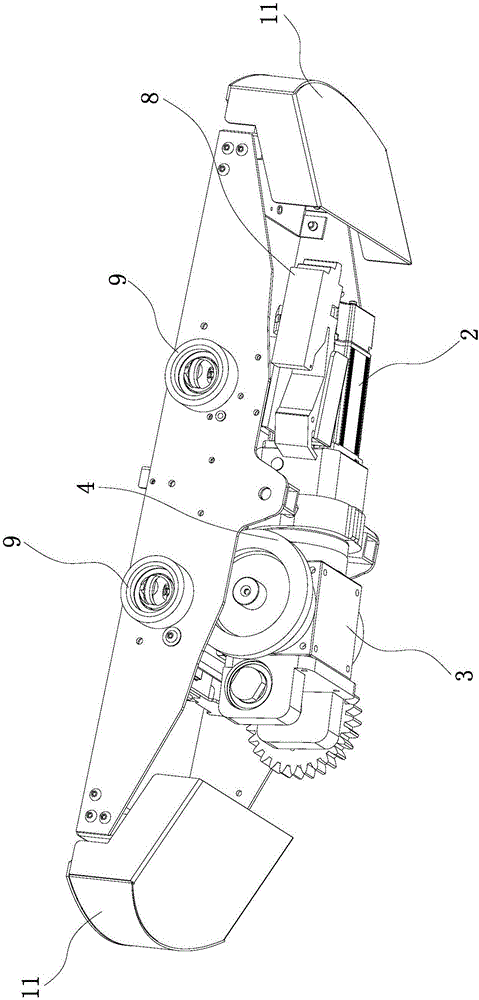

[0019] Example: see Figure 1 to Figure 3 , an intelligent box-type cargo trolley, including a chassis 1, a drive motor 2 is provided on the chassis 1, the output end of the drive motor is connected to a first-stage reducer 3, and the first-stage reducer 3 has two output ends, one of which is Connect the horizontal drive rubber wheel 4 to drive the trolley to run at high speed in the horizontal direction. The other output end of the primary reducer 3 is connected to the secondary automatic transmission mechanism 5. When the trolley moves on the vertical track, the secondary automatic transmission mechanism 5 passes through The rack on the vertical track drives the trolley to realize the power supply of high torque. The drive motor 2 used in the present invention is an AC servo motor, and the AC servo motor is controlled by a DC-to-AC servo driver 6 to output a constant large torque. Contact wires realize DC power supply, and the integrator 8 is also electrically connected wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap