Automatic rinsing type washing machine

An automatic flushing and washing machine technology, applied in the field of washing machines, can solve the problems of shortening the life of clothes, affecting life, and vibration of washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

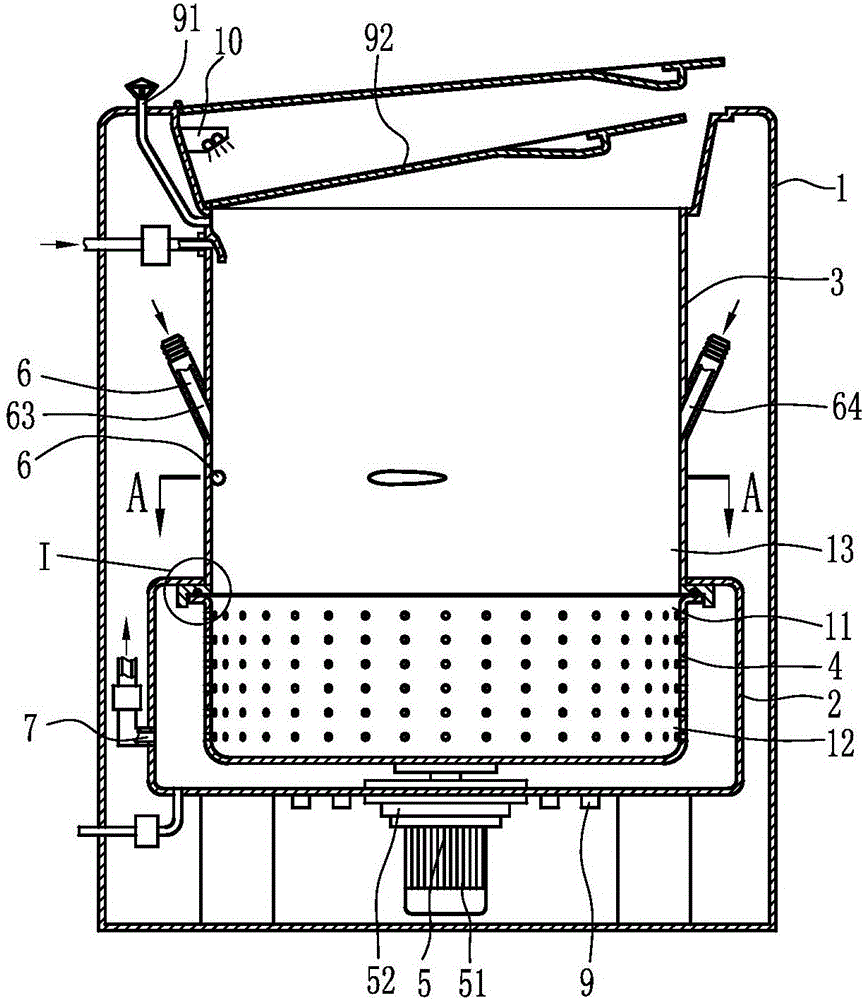

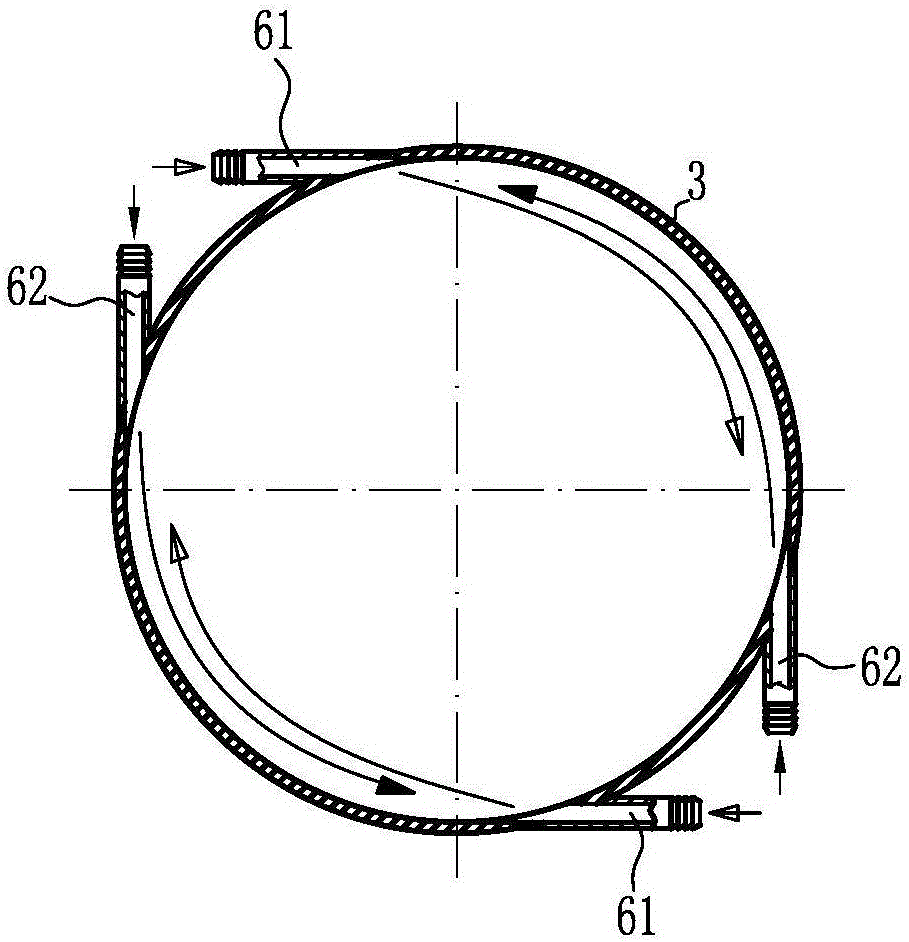

[0026] like Figure 1 to Figure 4 As shown, the automatic flushing washing machine includes a casing 1, a water collecting cylinder 2 is fixedly installed in the casing 1, and a washing cylinder 3 is fixed and sealed above the water collecting cylinder 2, and the inner diameter of the washing cylinder 3 is smaller than that of the collecting cylinder 3. The inner diameter of the water tank 2.

[0027] A dewatering basket 4 located below the flushing drum 3 is rotatably installed in the water collecting drum 2. The dewatering basket 4 and the flushing drum 3 form the flushing space of the present invention. The specific implementation of the flushing space will be described below. Description, the natural stacking height of the laundry to be washed should not exceed the dehydration basket 4 .

[0028] A dehydration drive device 5 is installed at the bottom of the water collecting cylinder 2. The dehydration drive device 5 should include a dehydration motor 51 and a gearbox 52 ...

Embodiment 2

[0037] like Figure 5 As shown, the structure of the automatic flushing washing machine is different from that of the first embodiment in that: the inner diameter 11 of the mouth of the dehydration basket is smaller than the inner diameter 12 of the dehydration basket body; in this embodiment, only the shape of the vertebral body is shown, and the The shape of the dehydration basket 4 can also be hemispherical or large hemispherical, so that the clothes can exist stably in the dehydration basket 4 during dehydration.

Embodiment 3

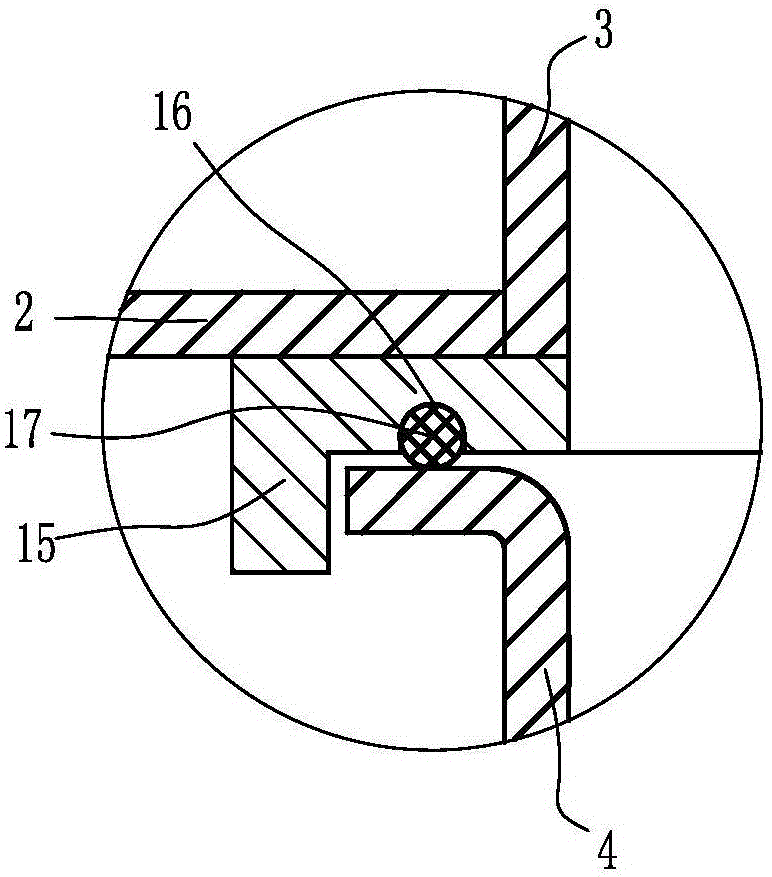

[0039] like Image 6 , Figure 7As shown in the figure, the structure of the automatic washing machine is different from that of the first embodiment in that: the inner diameter 11 of the mouth of the dehydration basket is larger than the inner diameter 13 of the washing tub; Image 6 As shown in the figure, an inner slideway 14 is arranged below the flushing cylinder 3 to ensure the stable rotation of the dehydration basket 4. The surface of the inner slideway 14 in contact with the dehydration basket 4 is provided with a groove 16, and the groove 16 A sealing ring 17 is installed inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com