Multi-position hole-type viscous damper

A viscous damper and multi-gear technology, which is applied in protective buildings/shelters, building components, and earthquake resistance, can solve the problems of large use limitations, single damping force providing multi-gear damping force, etc., to achieve The structure is simple, the damping force gear adjustment is sensitive, and the effect of manufacturing is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

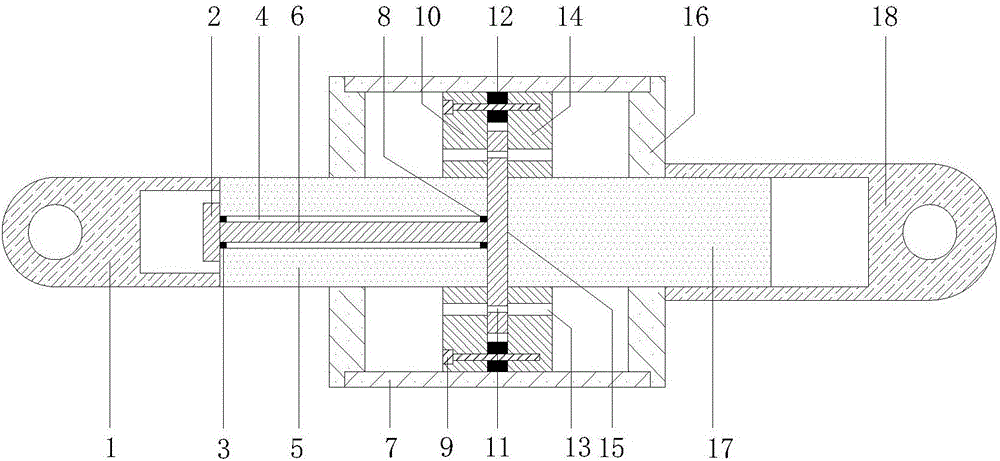

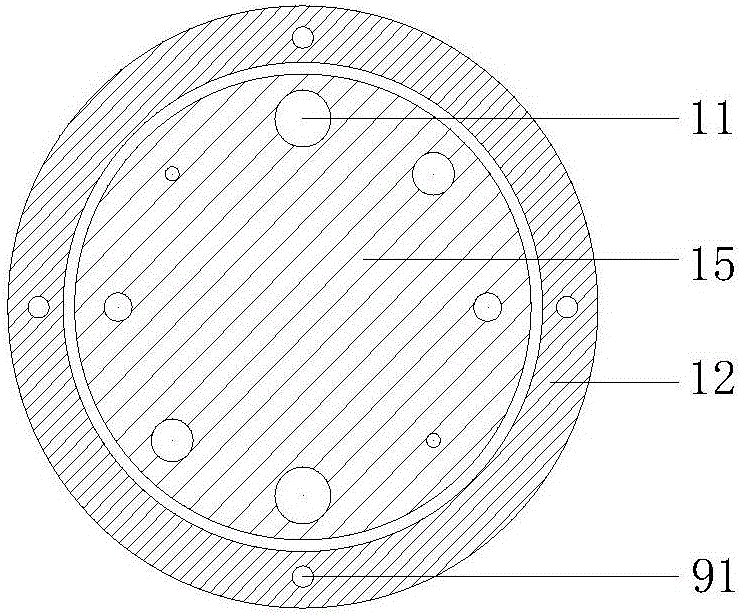

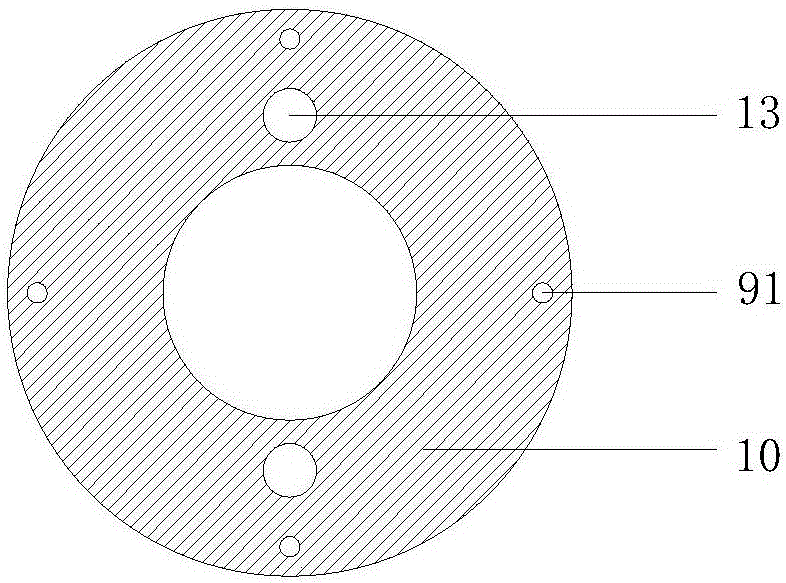

[0021] A preferred embodiment of a multi-gear pore-type viscous damper of the present invention, such as figure 1 As shown, a cylindrical cylinder body 7 is included in the figure, and end caps 16 are provided at its two ends, and the right end cap and the right connector 18 are welded together, and the end caps 16 and the cylinder body 12 are closely connected and sealed. Cylinder body 7 is provided with piston rod and piston, and this piston rod is made up of left piston rod 5 and right piston rod 17 two parts. Piston is made up of left piston 10 and right piston 14 two parts, and is connected together by bolt 9 and washer 12, and left piston 10 and right piston 14 are all provided with dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com