Determination method for optimal thickness of protection layer reserved for retaining piles in deep foundation pit blasting construction

A determination method and technology of protective layer, applied in the direction of foundation structure engineering, foundation structure test, excavation, etc., can solve the problem that the safety of the fencing piles cannot be well guaranteed, the construction safety and reliability cannot be guaranteed, and the engineering benefits cannot be guaranteed. Maximize blasting construction efficiency and benefits, improve construction efficiency and benefits, and avoid workload effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for determining the optimal thickness of the protective layer reserved for retaining piles in deep foundation pit blasting construction. The method for determining the optimal thickness of the reserved protective layer described in this embodiment is:

[0036] step 1

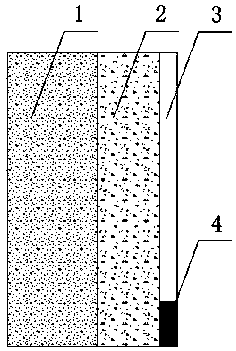

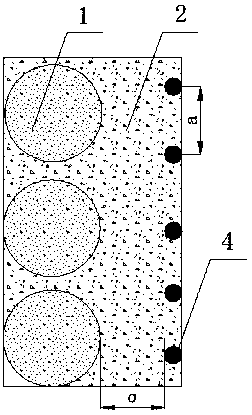

[0037] 1.1, such as figure 1 with figure 2 As shown, the optimal range for determining the optimal thickness δ of the reserved protective layer 2 is 0.3-0.8a, where a indicates that the distance between the blast holes 3 is 3000mm, that is, the optimal range of the optimal thickness δ of the reserved protective layer 2 is 900mm-2400mm.

[0038] 1.2. Determine the optimal thickness δ of the reserved protective layer 2 to be optimized to be 6, then reserve the i-th preferred thickness δ of the optimal thickness δ of the protective layer 2 i The i-1th to-be-optimized thickness δ of the optimal thickness δ of the adjacent reserved protective layer 2 i-1 thickness difference Reserve the optimal...

Embodiment 2

[0059] A method for determining the optimal thickness of the protective layer reserved for retaining piles in deep foundation pit blasting construction. The method for determining the optimum protective layer thickness described in the present embodiment is:

[0060] step 1

[0061] 1.1, such as figure 1 with figure 2 As shown, the optimal range for determining the optimal thickness δ of the reserved protective layer 2 is 0.3-0.8a, where a indicates that the distance between the blast holes 3 is 3000mm, that is, the optimal range of the optimal thickness δ of the reserved protective layer 2 is 900mm-2400mm.

[0062] 1.2. There are 11 to-be-optimized thicknesses reserved for the optimal thickness δ of the protective layer 2, then the i-th preferred thickness δ of the optimal thickness δ of the reserved protective layer 2 i The i-1th to-be-optimized thickness δ of the optimal thickness δ of the adjacent reserved protective layer 2 i-1 thickness difference in:

[0063] δ ...

Embodiment 3

[0087] A method for determining the optimal thickness of the protective layer reserved for retaining piles in deep foundation pit blasting construction. The method for determining the optimum protective layer thickness described in the present embodiment is:

[0088] step 1

[0089] 1.1, such as figure 1 and figure 2 As shown, the optimal range for determining the optimal thickness δ of the reserved protective layer 2 is 0.3-0.8a, where a indicates that the hole distance of the blast hole 3 is 3500mm; that is, the optimal range of the optimal thickness δ of the reserved protective layer 2 is 1050mm-2800mm.

[0090] 1.2. Determine the optimal thickness δ of the reserved protective layer 2 to be optimized to be 21, then the i-th preferred thickness δ of the reserved protective layer 2 i The i-1th thickness δ to be optimized with the adjacent reserved protective layer 2 i-1 thickness difference in:

[0091] δ 0 The initial thickness to be optimized to reserve the optimal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com