Anti-blocking contracting division device

The technology of a divider and an open impeller is applied in the field of anti-blocking dividers, which can solve the problems affecting the sample preparation efficiency, easy blockage of the rotating bucket, easy blockage of the feeding pipe, etc. The effect of avoiding blockage and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

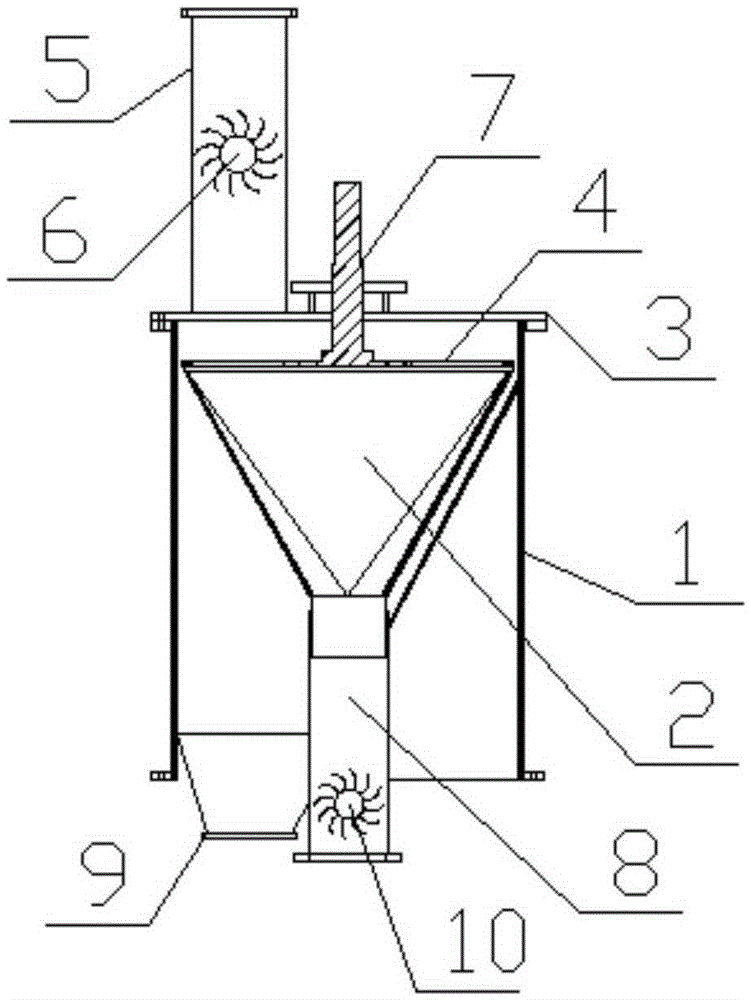

[0011] Such as figure 1 As shown in the figure, an anti-blocking shrinkage device includes a cylinder body 1, a cover plate 3 is provided above the cylinder body 1, a coal disposal pipe 9 is provided on the left part of the lower part of the cylinder body 1, and an inlet pipe 9 is provided on the left part above the cover plate 3. The material pipe 5 and the central area above the cover plate 3 are provided with a bucket rotating shaft 7 connected to the external gear motor of the cylinder body 1. 2 is symmetrically opened with two shrinking and dividing adjustable holes 4, and the bottom of the bucket 2 is connected with a coal sliding pipe 8. The middle part of the feeding pipe 5 is provided with a first open impeller 6, and the first open impeller 6 Rotating shaft one passes through the tube wall of the feed pipe 5 horizontally, and the end of the rotating shaft one out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com