A design method of a circular pressing circular printing device for paper products

A technology of printing device and design method, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of product appearance being difficult to meet quality requirements, overprinting deviation, etc., to save time and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A design method for a rotary printing device for paper products. The rotary printing device for paper products includes a web gravure printing machine, a web positioning holographic hot stamping machine, and web embossing, indentation, and die-cutting. The bit-linked self-positioning paper splicing and roll changing die-cutting machine specifically includes the following steps:

[0027] (1) Determine the number of circumferential typesetting of the web gravure printing machine according to the length of a single piece of printing paper, wherein, the first theoretical perimeter=the length of a single piece×the circumferential typesetting number of the web gravure printing machine, and then Determine the circumference range of the printing plate of the web gravure printing machine according to the theoretical circumference;

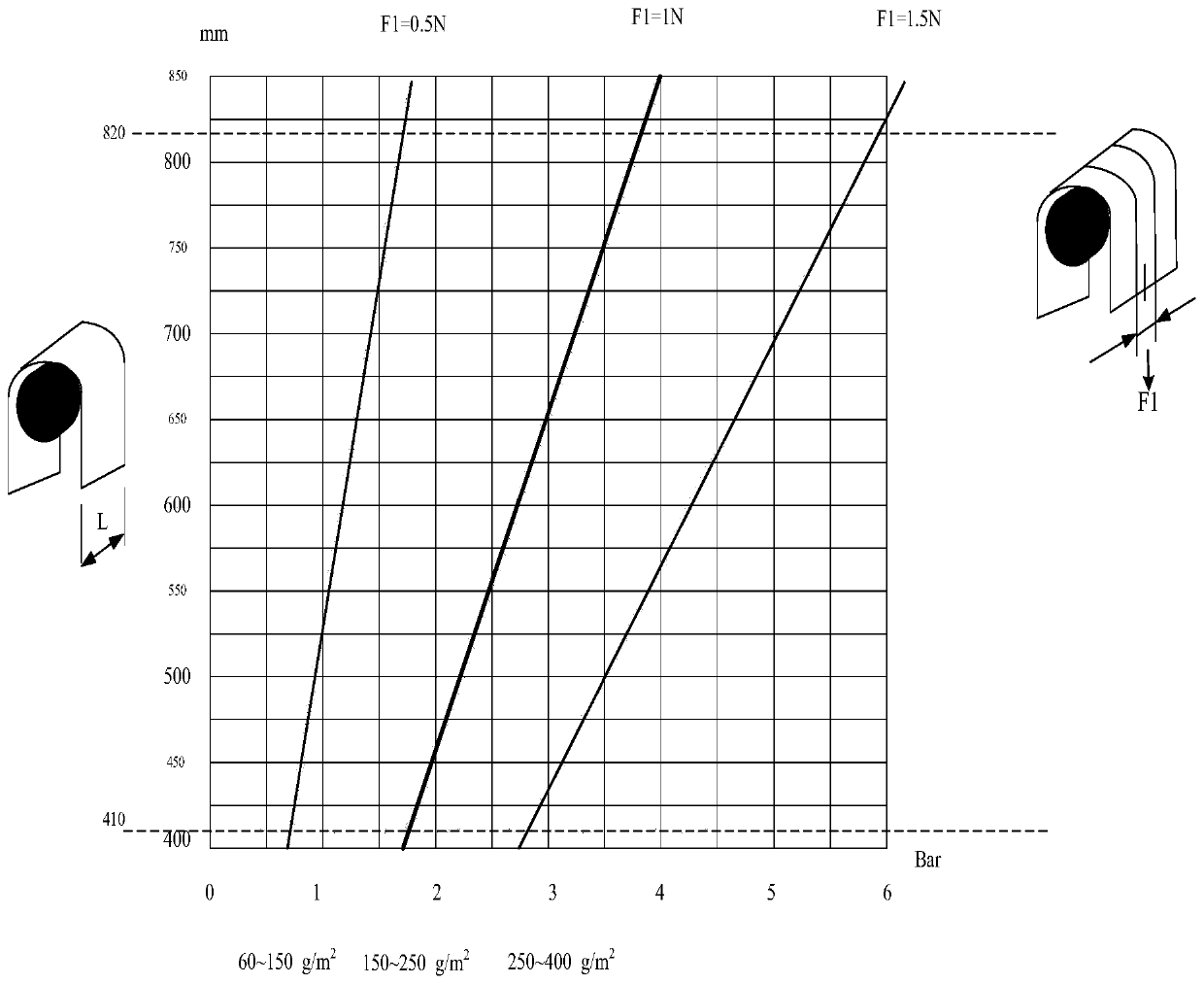

[0028] The tension and air pressure setting method of the web gravure printing machine is as follows: according to the width L of the printing paper, ...

Embodiment 2

[0044] Purchase and manufacture a web gravure printing machine, a web positioning holographic hot stamping machine, and a web embossing, indentation, and die-cutting three-station linkage self-positioning paper splicing and roll changing die-cutting machine; Through the intensive process, a new production technology of round pressing is formed. Design the setting of process parameters of the whole line and the requirements for equipment production.

[0045] According to the process standards and size requirements of a certain product (taking the circumferential direction as 98mm as an example), determine the following process standards to determine the equipment specification configuration:

[0046] ① Gravure printing process: Considering the operation suitability of gravure printing, select 6 blocks × 98 = 588mm (corresponding to the first theoretical circumference), and according to this requirement, determine the equipment specifications (the printing plate circumference ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com