Rotary current collector

A technology of rotating conduits and rotating parts, applied in the direction of current collectors, rotary current collectors, circuits, etc., can solve the problems of inconvenience for operators and high installation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] First, connect the electric wire to the incoming line end of the collector and fix it. One end of the distribution box of the tower crane is connected to the outgoing line end of the collector. The pole and the pole of the upper supporting seat are connected in a sliding contact type (to avoid straining the collector during vibration), and the upper seat drives the collector to rotate together under the drive of the slewing mechanism.

[0017] Description of drawings:

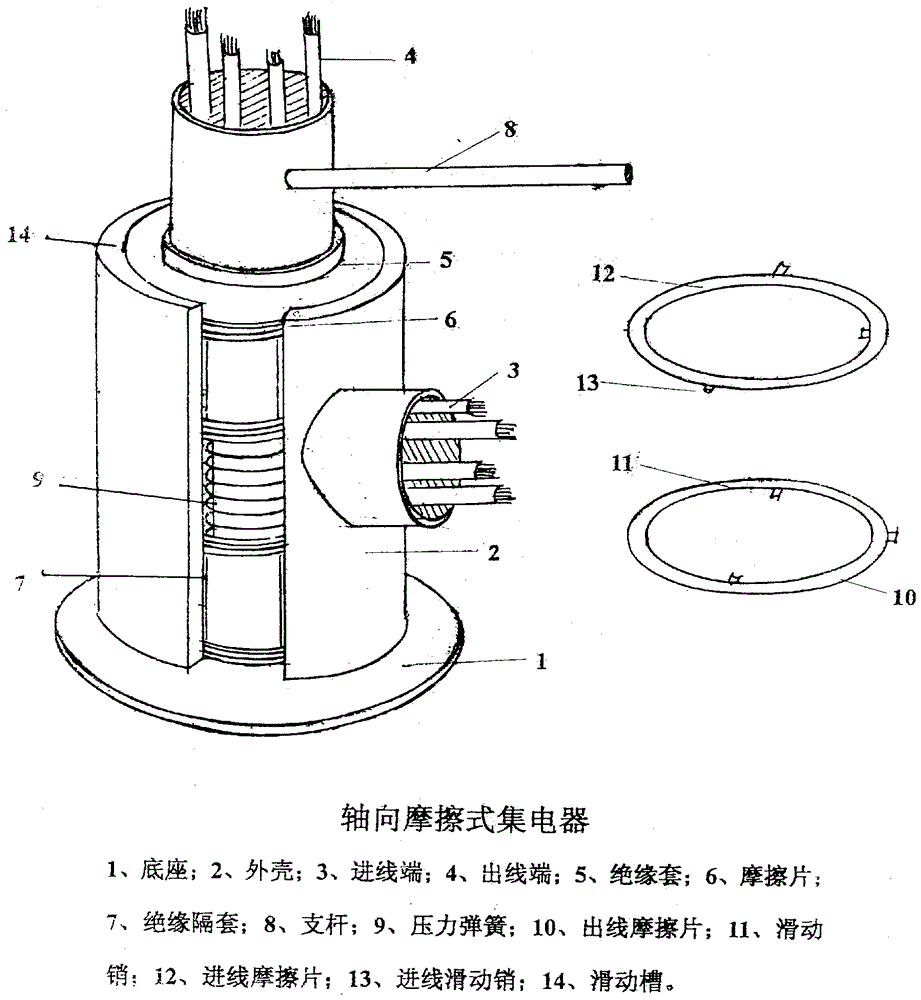

[0018] figure 1 is the diagram of the axial friction collector;

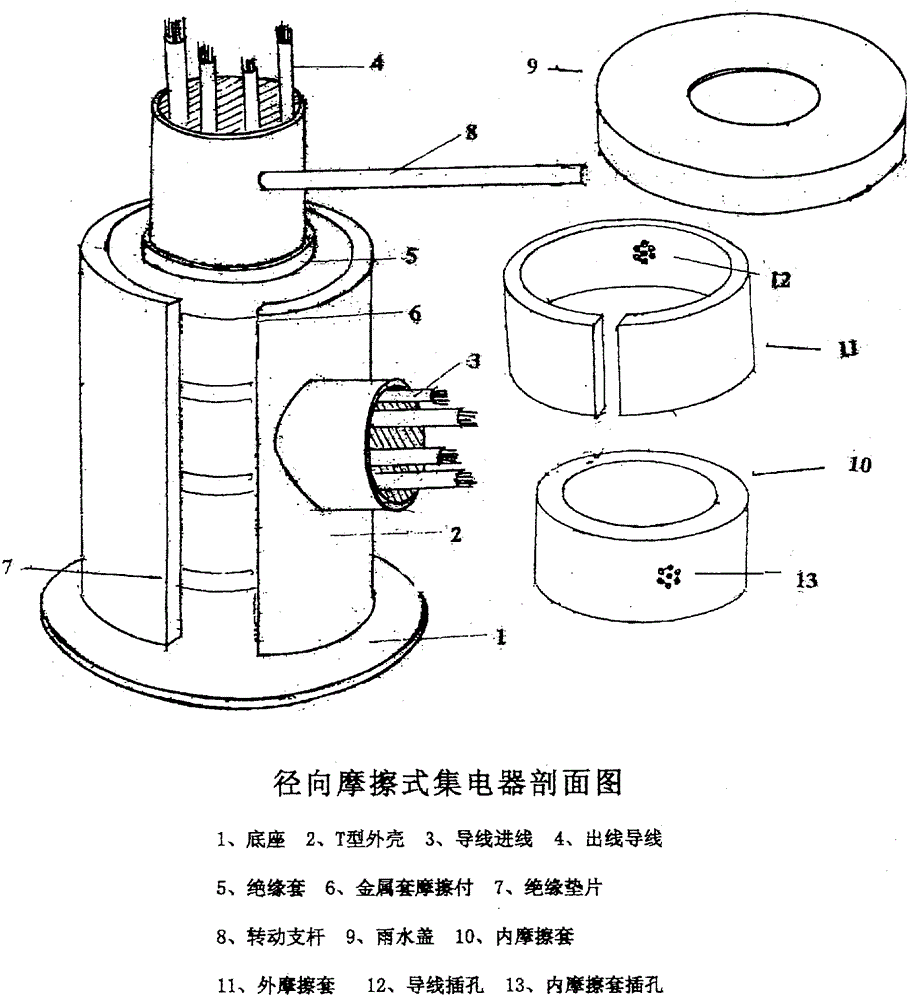

[0019] figure 2 is the diagram of the radial friction collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com