LED driving power supply flow measurement circuit and method

A technology of LED drive and drive circuit, which is applied in the direction of electric light source, electroluminescent light source, light source, etc., and can solve the problems of high cost of repeated design, single index of current measurement circuit, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in conjunction with the accompanying drawings.

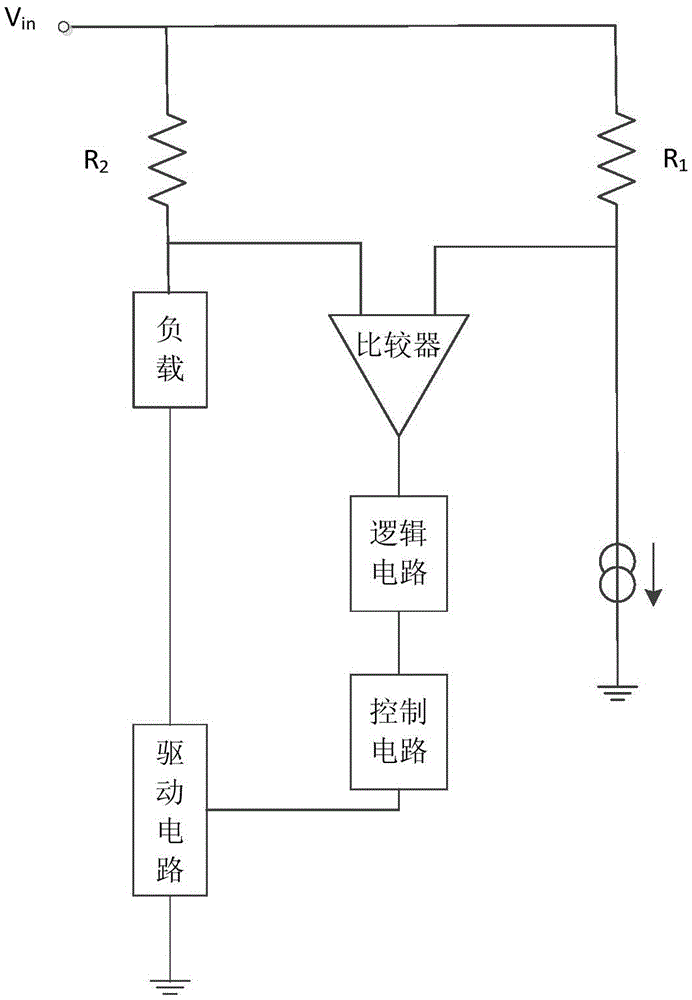

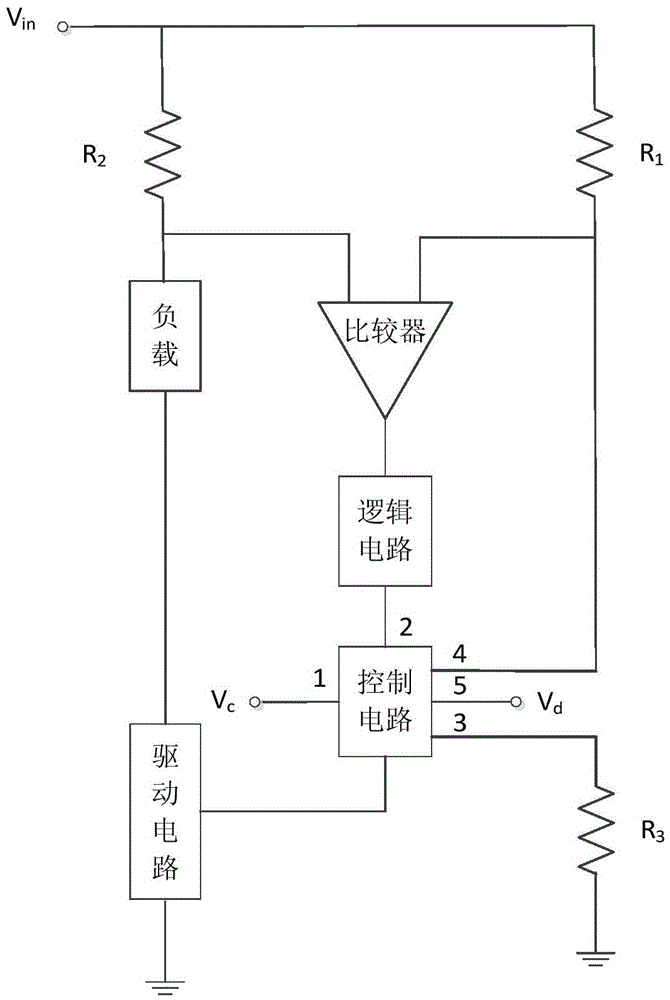

[0021] The present invention relates to a current measuring circuit of LED drive power supply, the schematic diagram of the circuit structure is as follows: figure 2 shown, including the current limiting resistor R 1 , Measuring resistance R 2 , comparator, logic circuit, drive circuit and load, also includes control circuit and configuration resistor R 3 , the control circuit of this embodiment has five input terminals and one output terminal, where the current limiting resistor R 1 One end of the input supply V in connection, the current limiting resistor R 1 The other end of the comparator is connected to an input end of the comparator (such as the non-inverting input end) and the fourth input end of the control circuit at the same time, and the current measuring resistance R 2 One end of the input supply V in connection, the current sense resistor R 2 The other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com