Efficient greenhouse plastic film guide lifting system

A lifting system and plastic film technology, applied in greenhouse cultivation, climate change adaptation, gardening, etc., can solve the problems of low work efficiency and labor, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

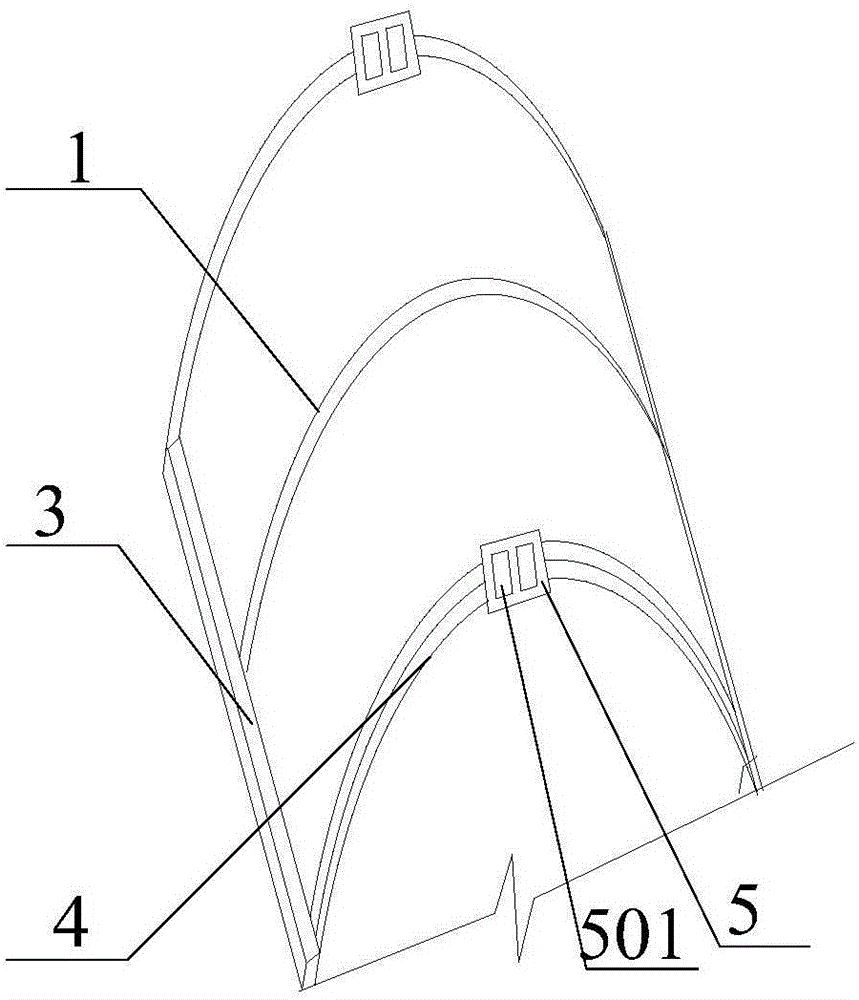

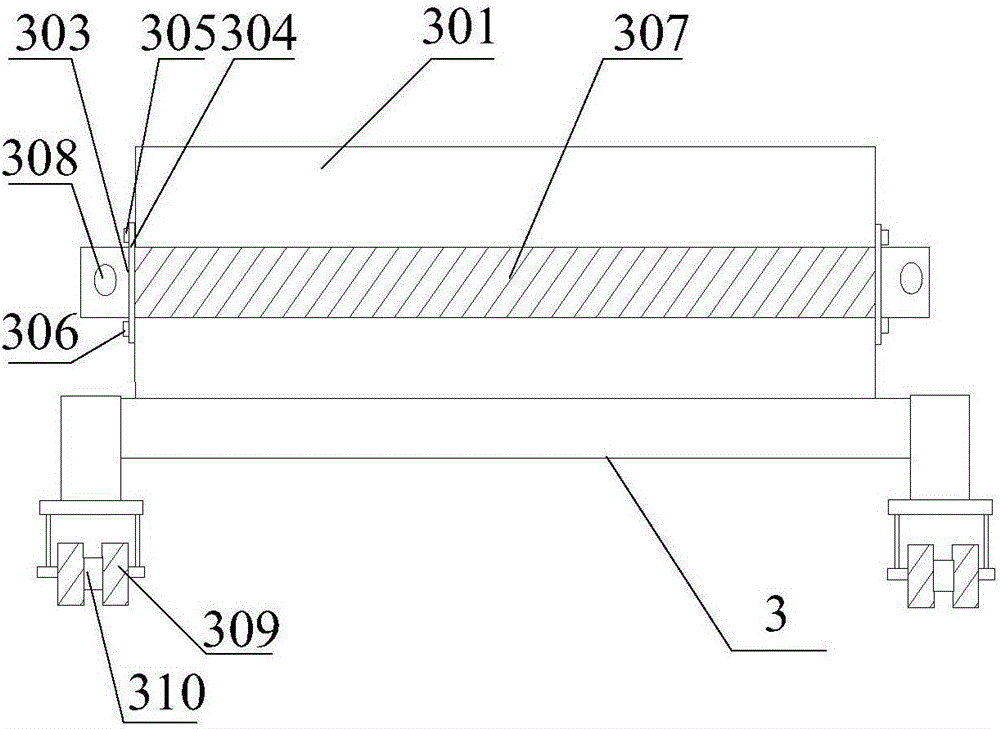

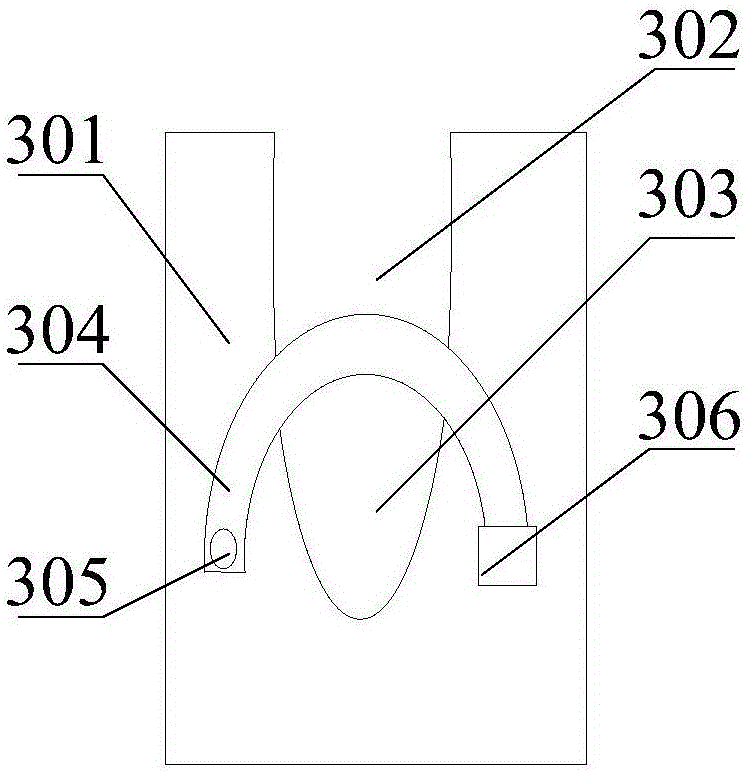

[0024] Such as figure 1 , figure 2 , image 3 As shown, a high-efficiency greenhouse plastic film guiding lifting system of the present invention includes an arched greenhouse 1, a plastic film is attached on the arched greenhouse 1, and clips are arranged on both sides of the arch wall of the arched greenhouse 1. Membrane device 3, the clamping device 3 is in contact with the ground surface, guide rails 4 and lifting mechanisms 5 are arranged on the arches at both ends of the arched greenhouse 1, and the guide rails 4 are about the center of gravity of the two lifting mechanisms 5 The connection axis is symmetrical. The clamping device 3 includes a rectangular groove 301, and an arc-shaped through hole 302 is arranged on the opposite side walls of the rectangular groove 301, and the arc-shaped through hole 302 is connected with the rectangular groove 301. The notches are connected. On the two side walls provided with the arc-shaped through hole 302, a movable limit bar 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com