Seedling stage bilateral film collection and unloading all-in-one machine

An all-in-one, bilateral technology, used in plant protection covers, botanical equipment and methods, gardening, etc., can solve the problems of high labor intensity and labor-time recovery rate, and achieve the effect of improving work efficiency and shortening auxiliary man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

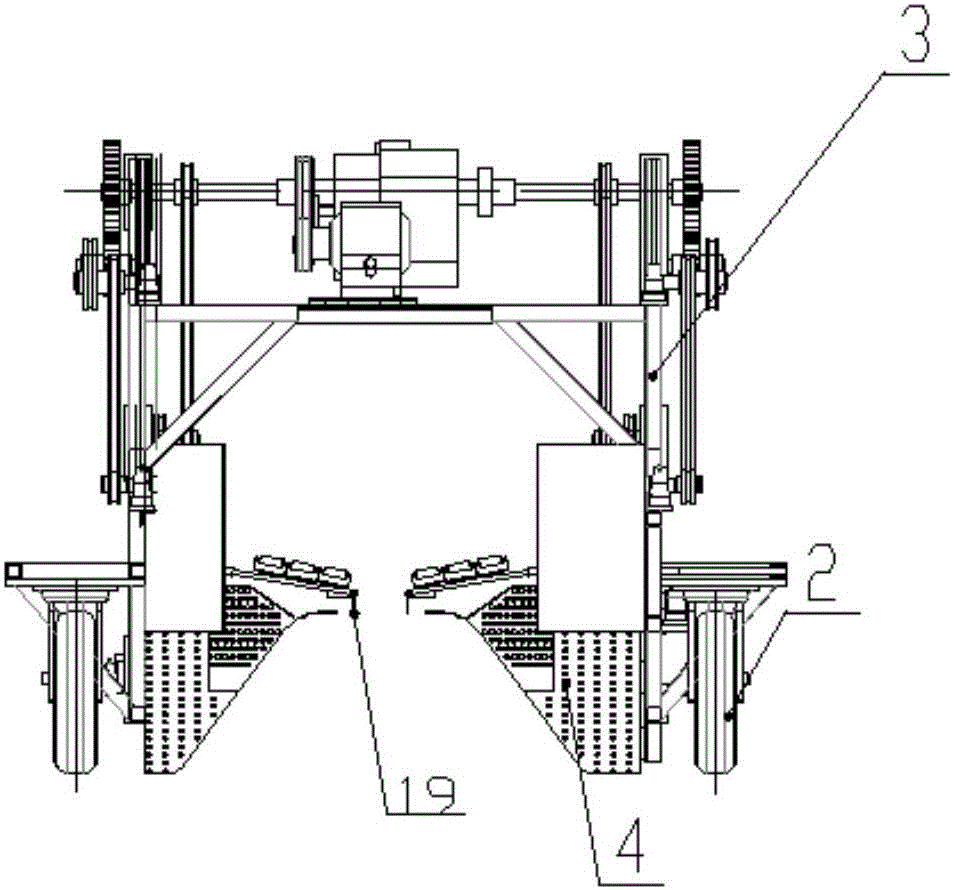

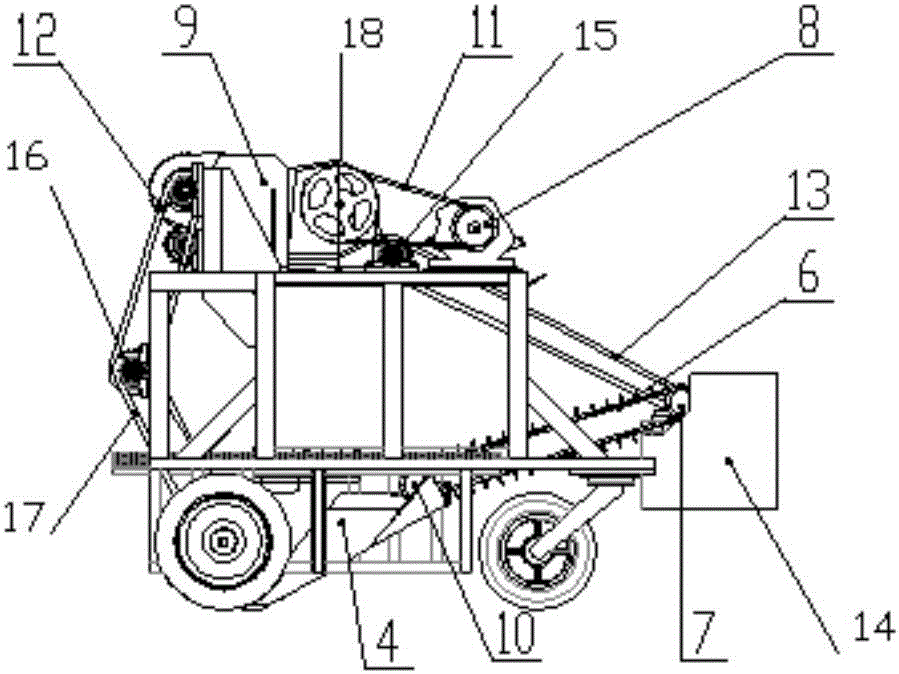

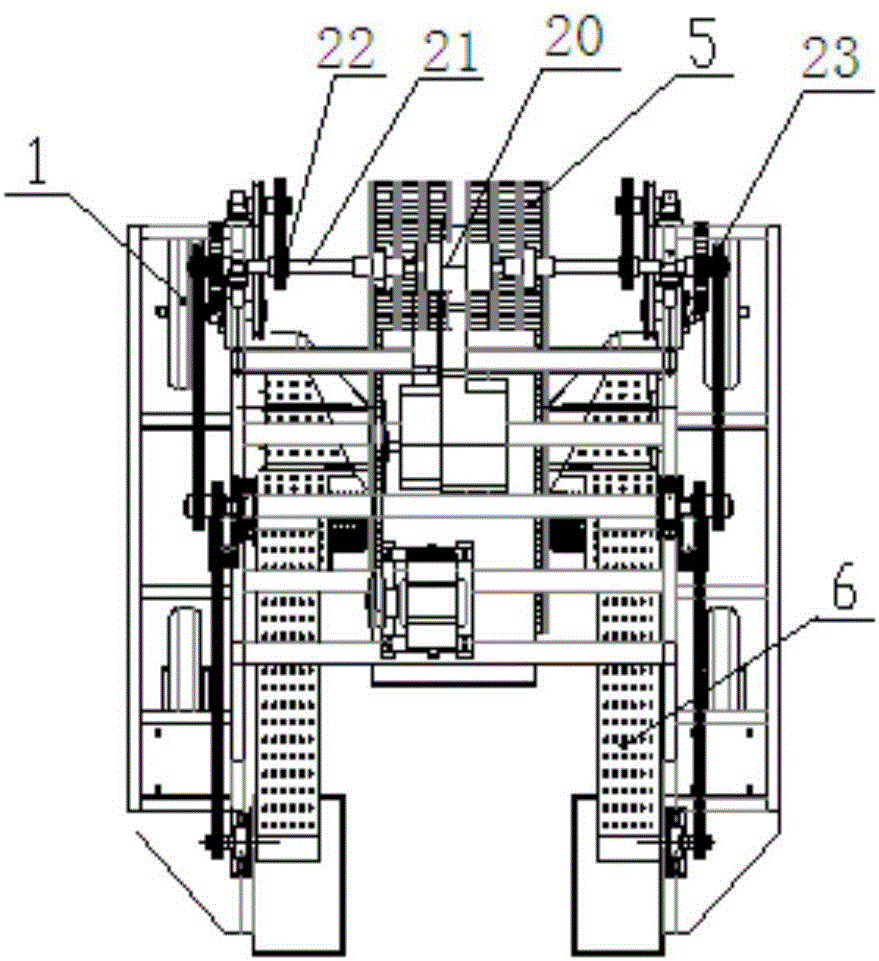

[0018] Embodiment of the present invention: a kind of double-sided film harvesting and film unloading integrated machine at the seedling stage, as shown in the accompanying drawings, includes a frame 3, a wheel assembly 1 is arranged at the rear end of the bottom of the frame 3, and symmetrically arranged at the front end of the bottom of the frame 3 The rubber universal wheel 2 is provided with a film receiving box 14 on one side of the rear part of the frame 3, and a seedling-supporting part 5 is arranged on one side of the frame 3 inside, and a plastic film shovel 4 is set directly below the seedling-supporting parts 5, and the plastic film scraper 4 is connected to the frame. Fixedly connected, a transmission structure is set between the film shovel 4 and the film collection box 14, the transmission structure includes a driven roller 10 located at the tail of the film shovel 4, a driving roller 7 located at the entrance of the film collection box 14, and a toothed conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com