Seedling stage mulching film rolling recycling machine

A recycling machine and film rolling technology, which is applied in the field of agricultural machinery, can solve the problems of high labor intensity and time-consuming recycling rate, and achieve the effects of improving work efficiency, simple and convenient structure, and convenient continuous film rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

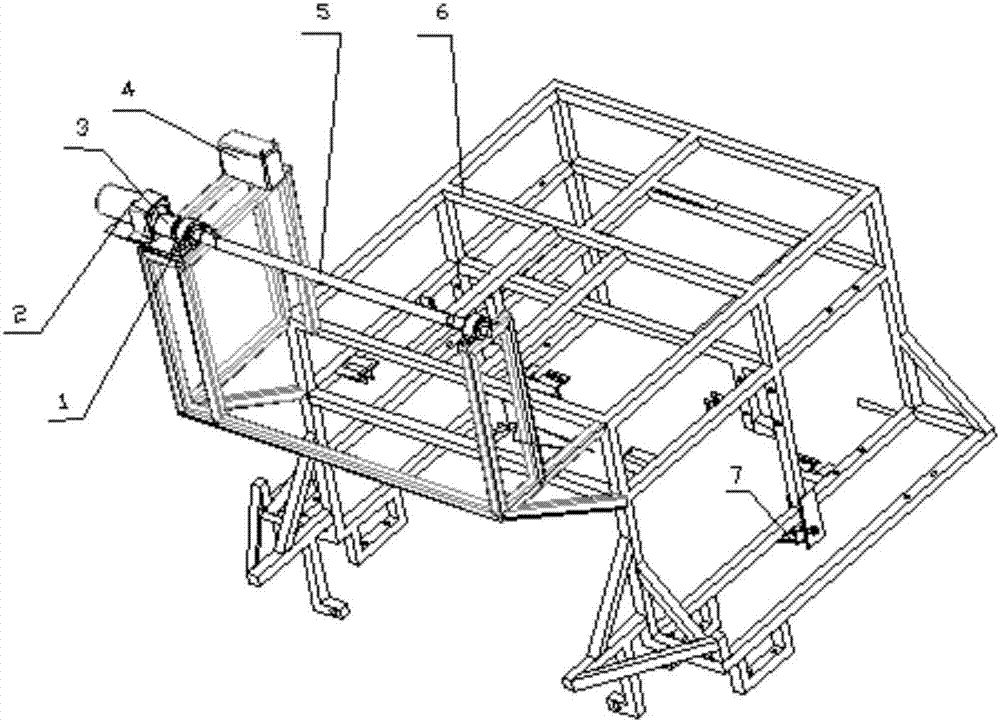

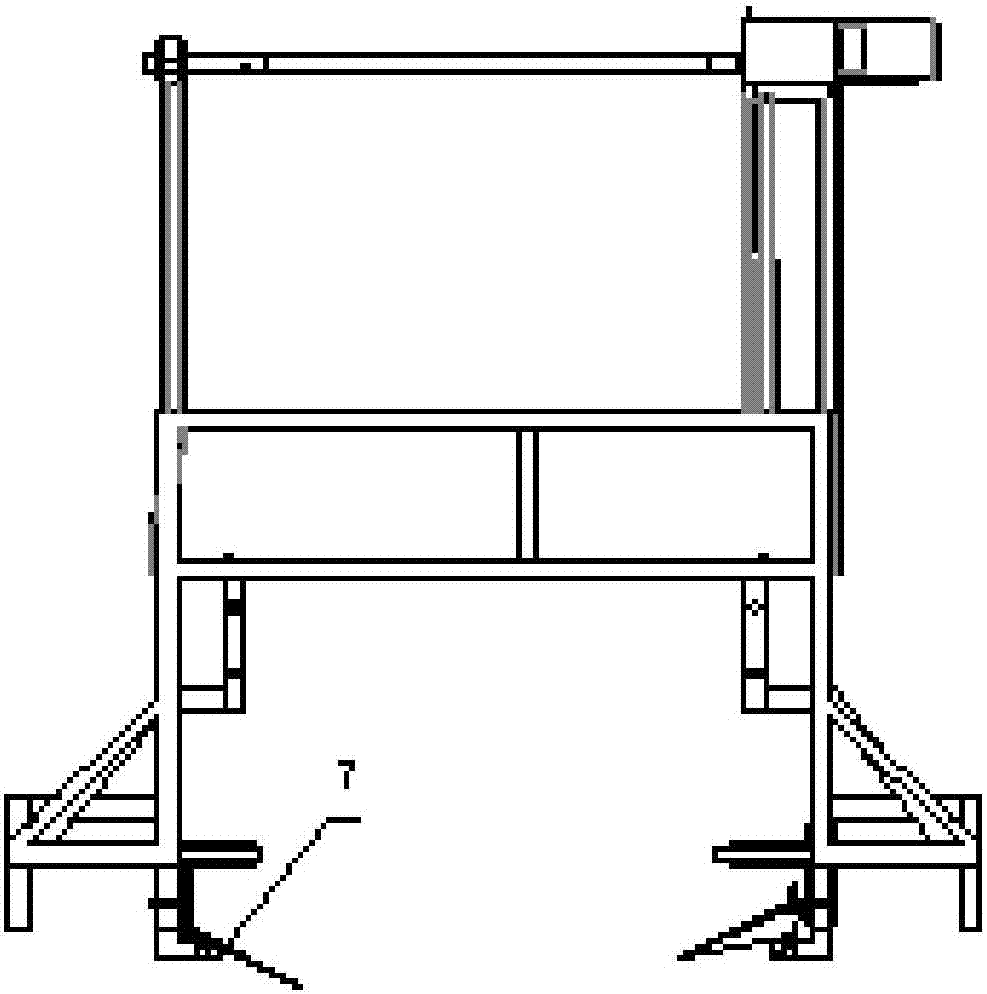

[0010] Embodiment of the present invention: a kind of seedling stage mulch film roll recovery machine, as shown in the accompanying drawing, comprises roll film recovery machine frame 6, and cutter 7 is symmetrically arranged on both sides of the bottom of roll film recovery machine frame 6, and is rolled back A roll film roller shaft 5 is arranged on the top of the film recovery machine frame 6 rear end, and a bearing block 1 with a bearing is arranged on both sides of the film roll shaft 5 and the bearing block 1 with a bearing is fixed on the roll film recovery machine frame 6, A motor 2 is arranged at one end of the roll film roller shaft 5, the storage battery 4 is located at one side of the motor 2 and the motor 2 and the storage battery 4 are all fixed on the roll film recovery machine frame 6, and the motor 2 and the roll film roll shaft 5 are passed through a coupling The device 3 is connected together, and the film at the seedling stage is wound around the roll film r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com