Rotating disc type quick drying device for grains

A grain granule, turntable technology, applied in the direction of storing seeds by drying, can solve the problems of difficult drying of grains, many uncertain factors, and low drying efficiency, so as to avoid uneven heating, reduce waste, and improve drying. Effects and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

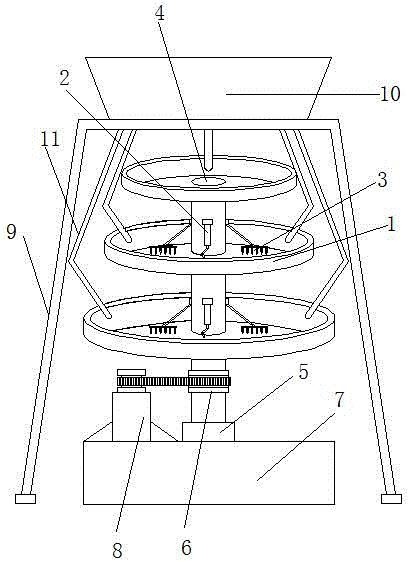

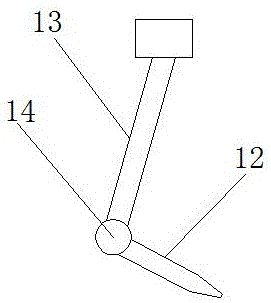

[0018] Refer to attached Figure 1-2 The rotary disc type quick-dryer for grain grains shown includes several rotating trays 1, the inner diameters of which are sequentially increased from top to bottom, and a vertical rotating shaft 4 is integrally arranged in the center of several said rotating trays 1, And the vertical rotating shaft 4 is divided into several equal-height shaft joints 2 by several rotating trays 1, the bottom of the vertical rotating shaft 4 is arranged in the bearing 5, and a rotating block 6 is also arranged on the vertical rotating shaft 4 , the bearing 5 is arranged on the base 7, and the motor 8 connected to the rotating block 6 is arranged on the base 7. The present invention drives the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com