Micro-pressure insulation anti-oxidative electric cooker

An anti-oxidation, rice cooker technology, applied in cooking utensils, household appliances, applications, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

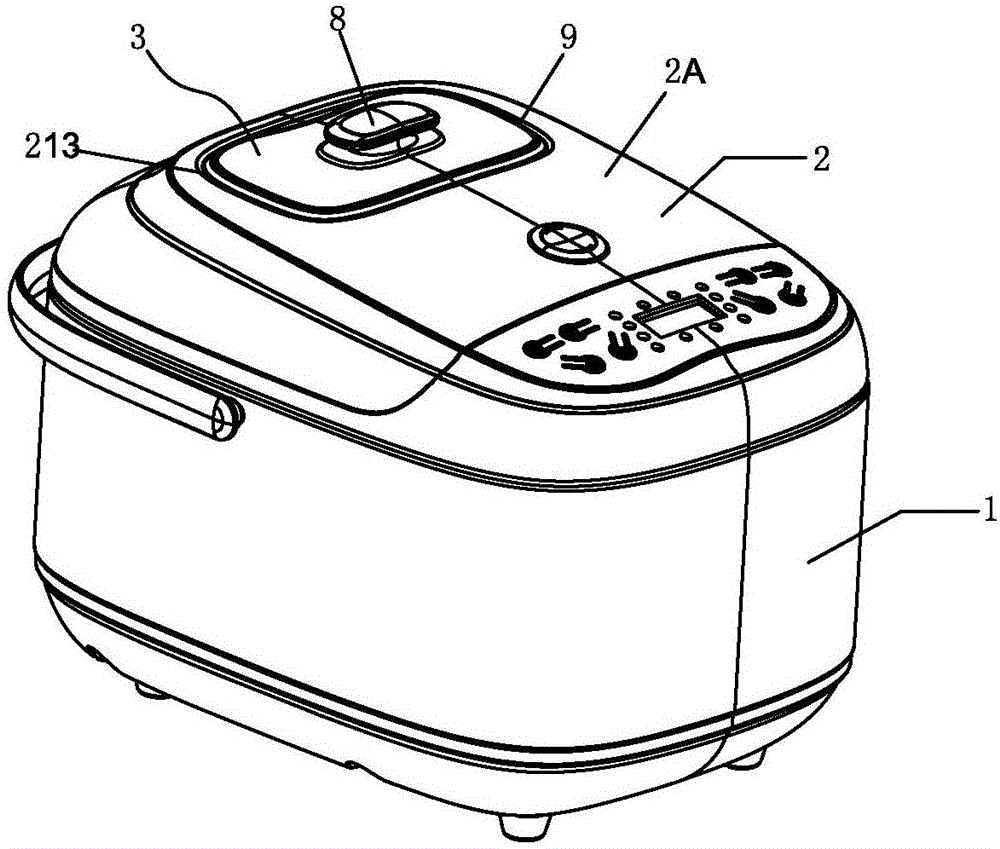

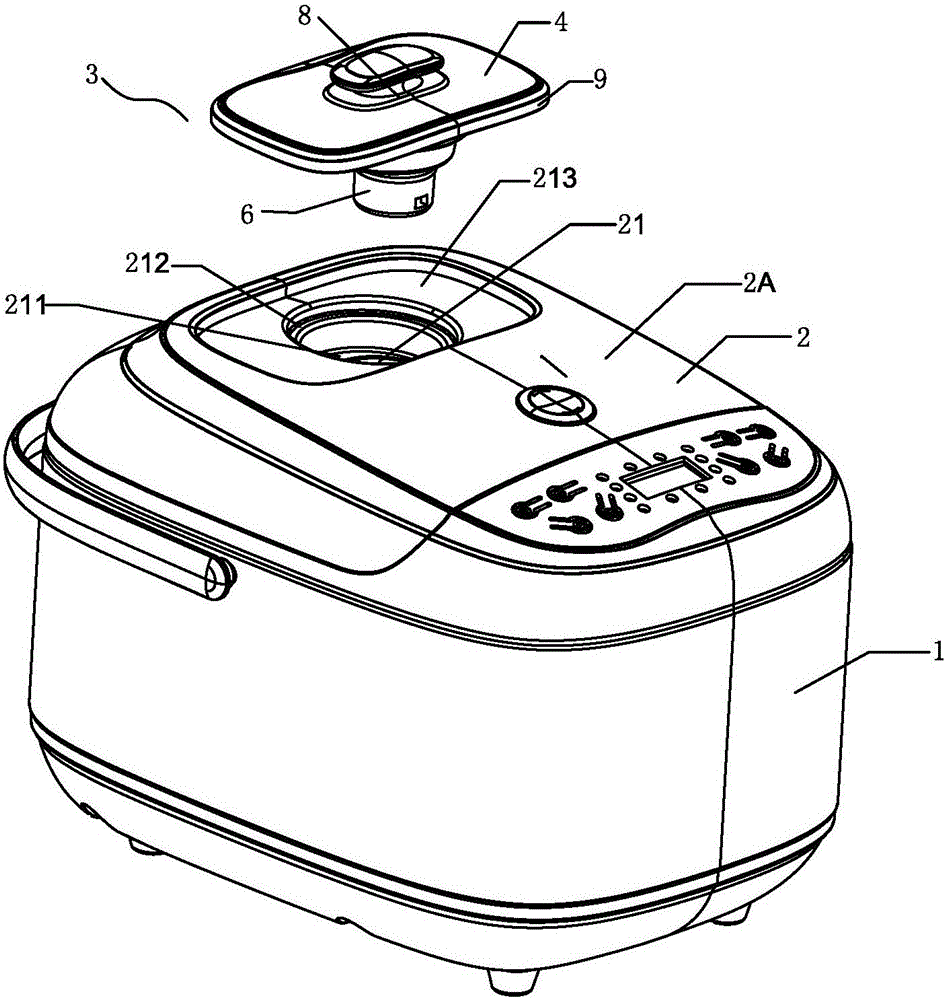

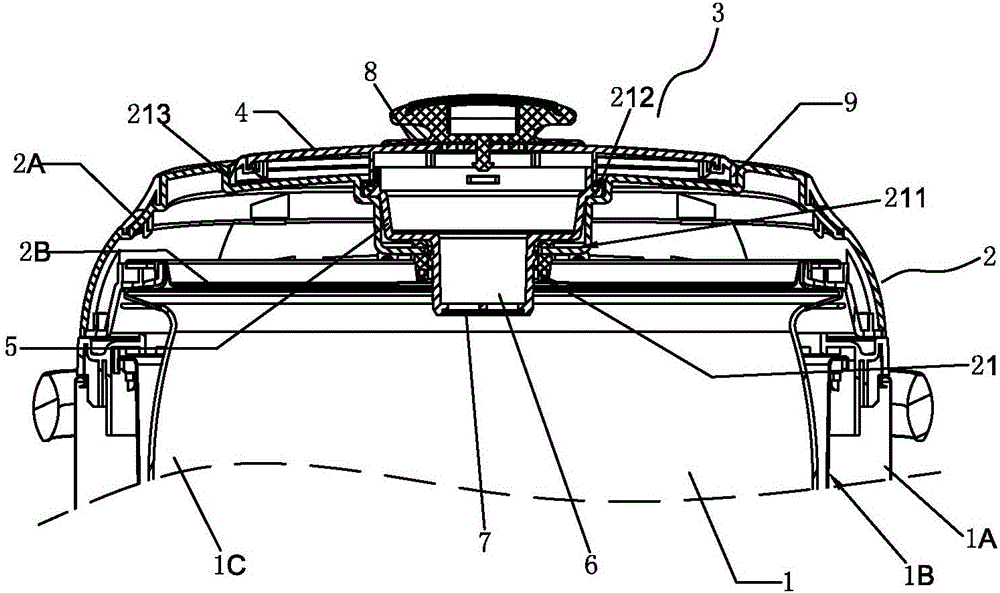

[0031] Such as figure 1 As shown, a micro-pressure heat preservation and anti-oxidation electric rice cooker includes a pot body 1, a pot cover 2 and an exhaust valve 3, and the pot body 1 includes a shell 1A, a middle layer 1B, a liner 1C and an electric heating plate (not shown in the figure). shown), the pot cover 2 includes an outer cover 2A and an inner steel cover 2B, and the pot cover 2 is provided with an exhaust valve installation hole 21; the exhaust valve 3 is detachably matched with the exhaust valve installation hole 21.

[0032] The exhaust valve 3 includes a valve cover 4, a valve seat 5, a valve body 6, a return film 7 and a float cover 8;

[0033] The valve cover 4 includes a cover body 41, a guide hole 42 arranged in the center of the valve body, an exhaust hole 43 surrounding the guide hole, a steam chamber 44 with a lower opening on the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com