Gear-ring-unwinding high-speed counter-current chromatograph

A high-speed countercurrent chromatography and unwinding technology, which is applied in the field of separation and analysis instruments, can solve the problems of inability to adjust, poor instrument stability, and limited instrument functions, so as to broaden the scope of use, prolong the service life, and reduce the noise of the instrument. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

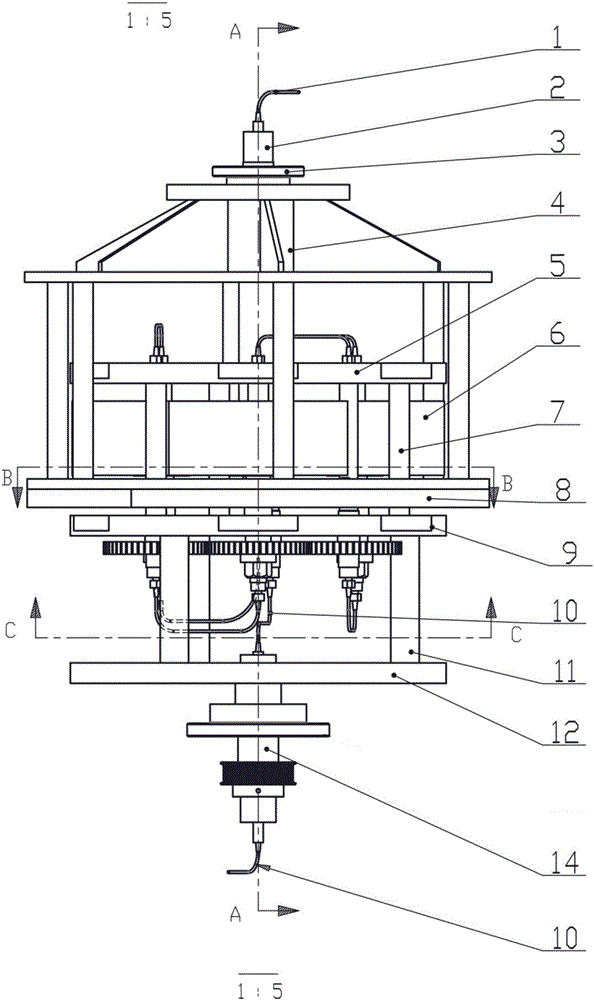

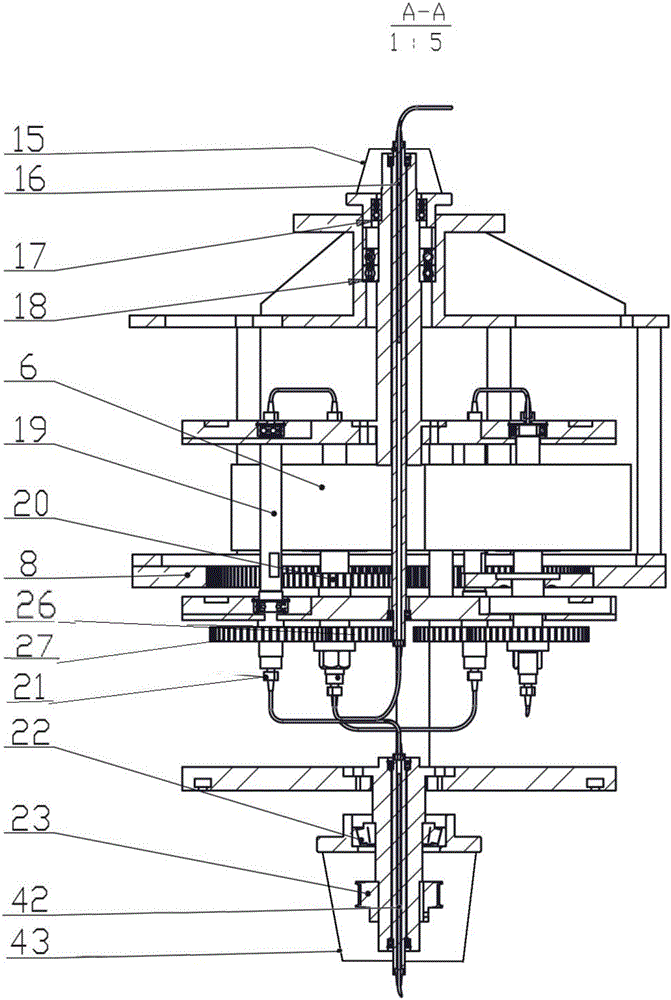

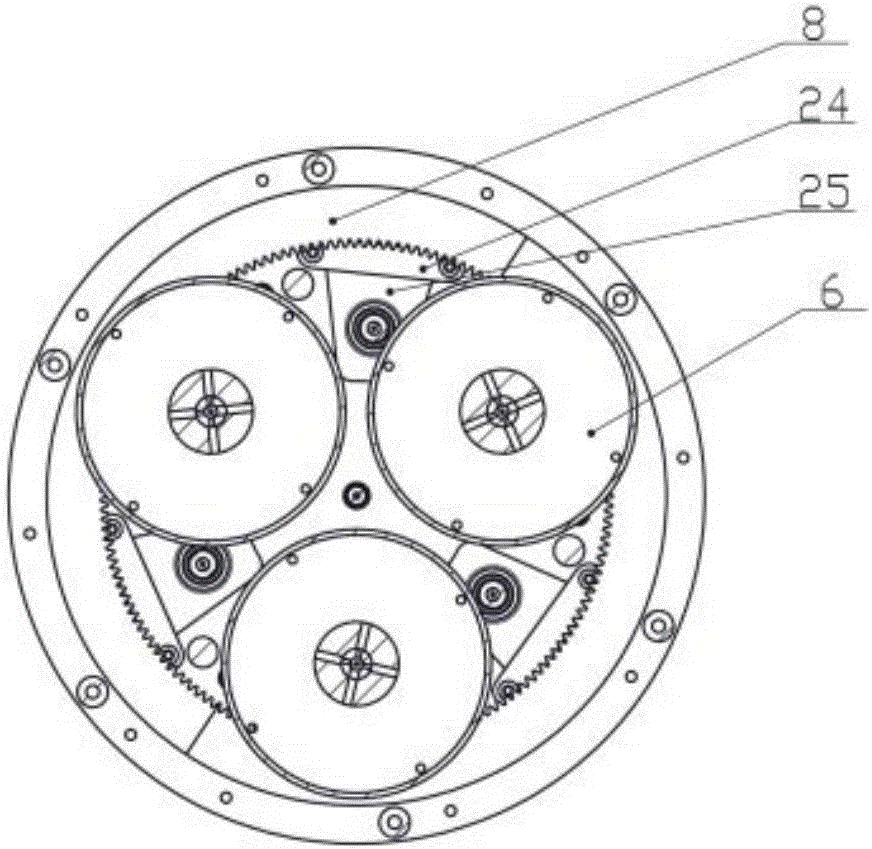

[0042] Such as Figure 1-2 As shown, a high-speed countercurrent chromatograph with unwound gear rings includes a rotating support, and the rotating support includes an upper plate 5, a middle plate 9 and a lower plate that are installed in sequence and connected into one body through a connecting column 7 and a connecting column 11. Disc 12, above the middle disc 9 is fixed with an unwinding gear ring 8 coaxial with it, the lower disc 12 is driven to rotate by a drive shaft 14, and the unwinding gear ring 8 is not fixed and the teeth of the unwinding gear ring 8 are distributed on its inner ring, and along the circumferential direction of the inner ring of the unwinding gear ring 8, there are a plurality of gears I20 meshed with it, and the gears I20 between adjacent groups are not meshed. The gear I20 drives the separation column to rotate, and a gear II26 is coaxially installed below each of the gears I20, the gear II26 meshes with the gear III27, and the gear III27 drives ...

Embodiment 2

[0054] Embodiment 2 The drawings of this embodiment are not shown in the drawings.

[0055] The high-speed countercurrent chromatograph with unwound gear rings includes a rotating support, and the rotating support includes an upper plate, a middle plate and a lower plate that are installed in sequence and connected into one body. The unwinding gear ring of the shaft, the lower plate drives its rotation through a drive shaft, the unwinding gear ring is fixed, and the teeth of the unwinding gear ring are distributed on its inner ring, and along the unwinding teeth There are multiple groups of gears meshing with the inner ring of the ring, and the gears between adjacent groups are not meshing. Each group of gears includes two gears that mesh with each other, one of which drives a separation column, and the other gear drives a solution. Around the shaft, the separation column is installed on a separation shaft, the upper end of the unwinding shaft and the separation shaft are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com