Underwater welding device and method for resistance welding

An underwater welding and resistance welding technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of the tip of the parallel electrode welding head being easily oxidized and damaged, damage to the welding electrode, and peeling of the substrate pad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

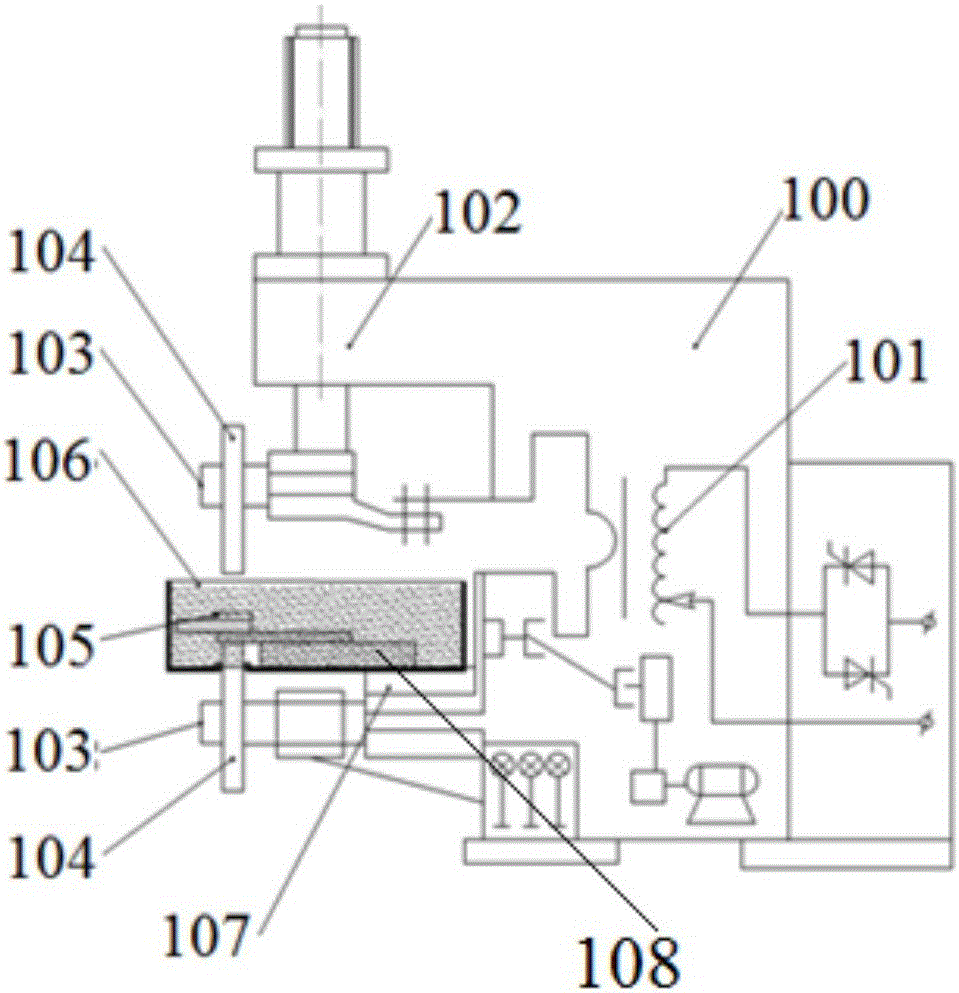

[0017] In order to make the purpose, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0018] First of all, it should be noted that the resistance welding underwater welding proposed by the present invention uses resistance welding equipment to weld the welded workpiece submerged in water in the workpiece water tank. For the convenience of description, unless otherwise specified, this manual uses the abbreviation "resistance welding underwater welding".

[0019] As known to those skilled in the art, resistance welding includes two ways of double-sided spot welding and single-sided spot welding, wherein placing two welding electrodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com