Method for producing aluminate high-temperature adhesive by metal calcium residue

A technology of high temperature binder and metal calcium, which is applied in the field of high temperature binder production of aluminate from metal calcium slag, can solve the problems of ignorance of the application value of calcium slag, environmental pollution, etc., so as to save bauxite resources, save mine resources, The effect of saving a lot of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The invention provides a method for producing aluminate high-temperature binder from metal calcium slag.

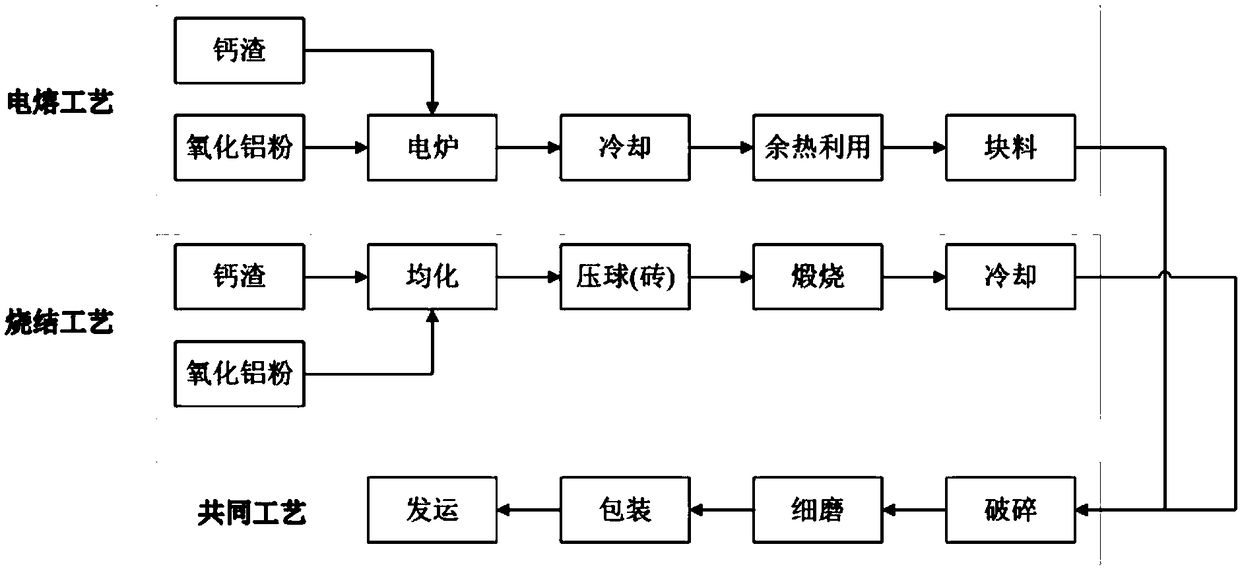

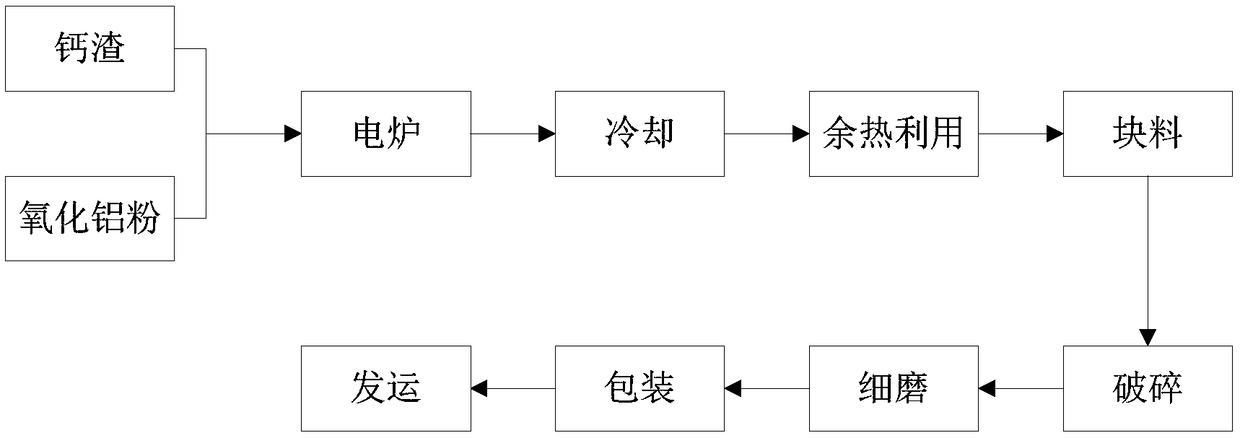

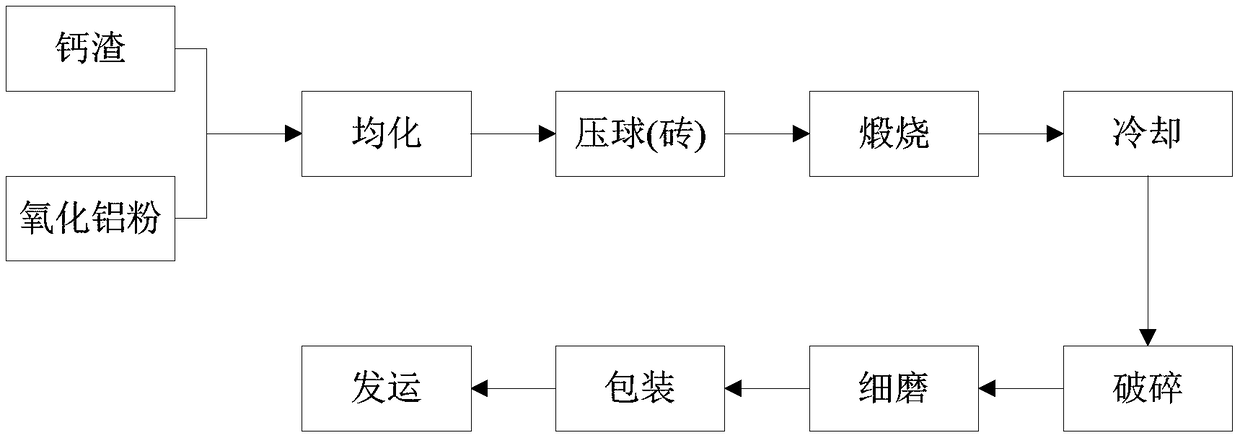

[0025] Such as figure 1 , figure 2 and image 3 As shown, the method firstly crushes calcium metal slag raw materials of different particle sizes, then adds alumina powder to the crushed calcium metal slag according to the grade of the high-temperature binder, and finally processes it through electrofusion or sintering process , after cooling, the high-temperature binder is obtained by crushing and grinding.

[0026] The main crystal phases of the high-temperature bond prepared by this method are calcium aluminate (CA) and calcium dialuminate (CA) 2 ), belongs to the high-temperature phase, and can be used as a high-temperature binder. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com