Assembling fixture and assembling method

A technology for assembling fixtures and fixtures, which is applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., and can solve the problems of high processing cost and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

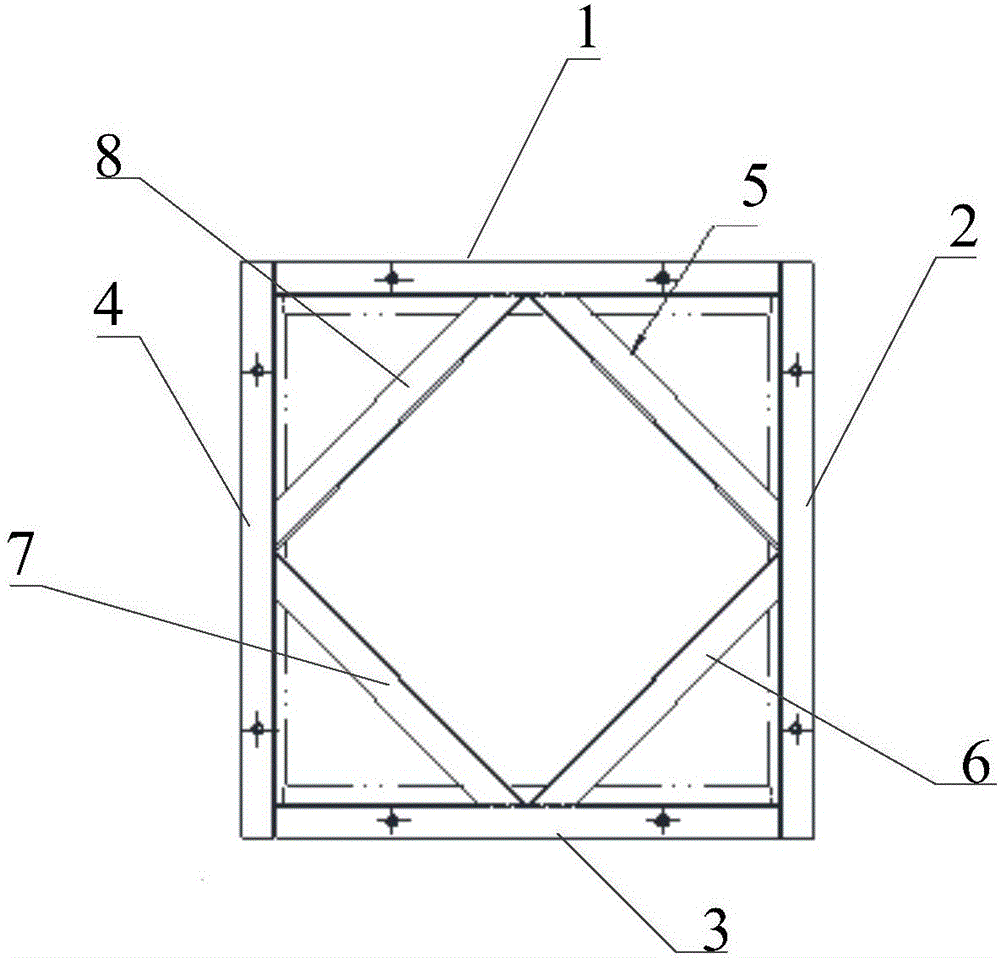

[0038] This embodiment provides an assembly fixture, such as figure 1 As shown, the fixture includes: a first beam 1, a second beam 2, a third beam 3, and a fourth beam 4; wherein, the first beam 1, the second beam 2, and the third beam 3 and the fourth crossbeam 4 are connected in turn to form a positioning frame; the positioning frame is used for positioning the bottom door frame of the funnel car, and the shape and size of the positioning frame are consistent with the shape and size of the bottom door of the bottom frame of the funnel car.

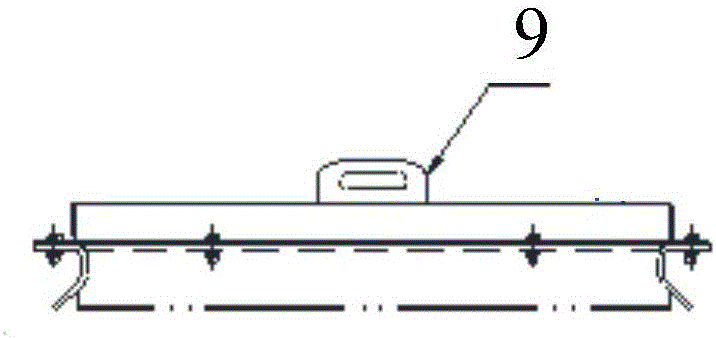

[0039] The positioning frame is provided with a positioning hole, and the size and position of the positioning hole are consistent with the size and position of the bolt hole on the bottom door frame and the size and position of the bolt hole on the bottom door. Wherein, when welding the positioning frame, the positioning frame is assembled and welded on a standard platform, and the working surface is milled flat after the assembly and ...

Embodiment 2

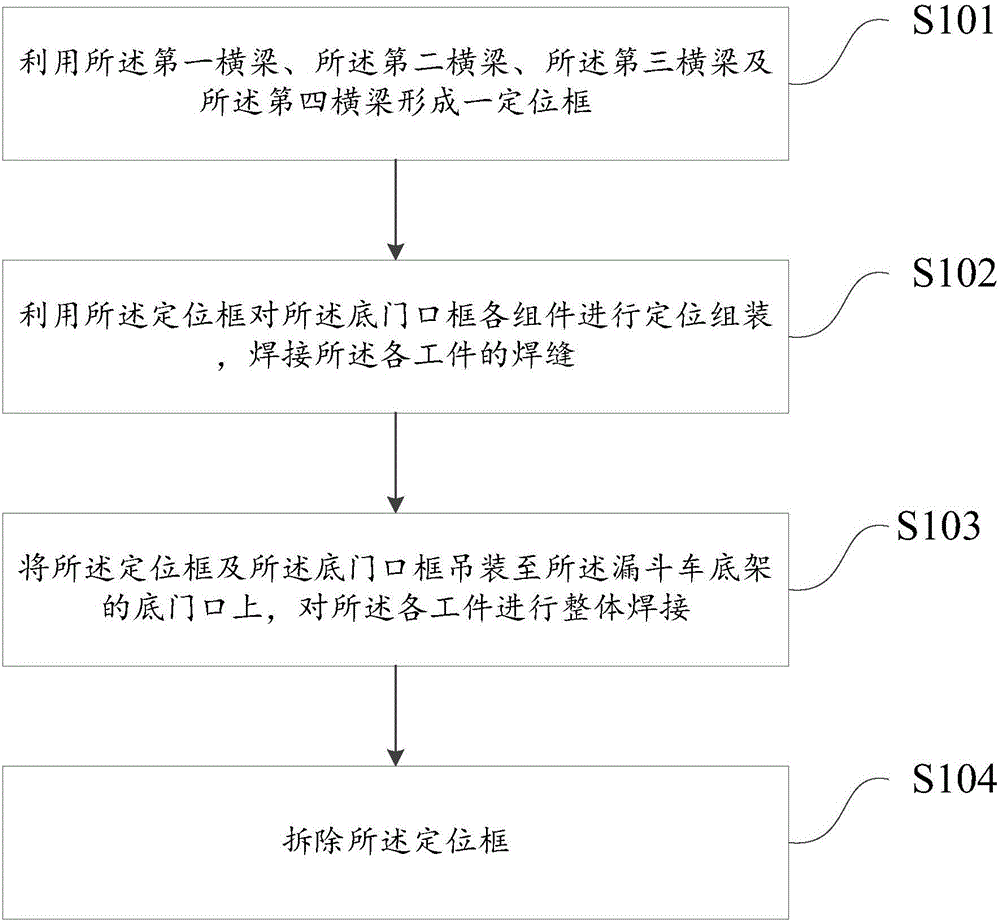

[0058] Corresponding to Embodiment 1, this embodiment also provides an assembly method, such as image 3 As shown, the method includes:

[0059] S301. Using the first beam, the second beam, the third beam and the fourth beam to form a positioning frame.

[0060] In this step, see figure 1 , connecting the first crossbeam 1, the second crossbeam 2, the third crossbeam 3 and the fourth crossbeam 4 in sequence to form a positioning frame; the positioning frame is used for positioning the bottom door frame of the hopper car, The shape and size of the positioning frame are consistent with the shape and size of the bottom door of the hopper car chassis;

[0061] The positioning frame is provided with a positioning hole, and the size and position of the positioning hole are consistent with the size and position of the bolt hole on the bottom door frame and the size and position of the bolt hole on the bottom door. Wherein, when welding the positioning frame, the positioning frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com