Numerically-controlled pipe thread lathe adopting laser welding

A technology of laser welding and CNC lathes, which is applied in the field of CNC lathes, can solve problems such as inability to weld, long time, inconvenient automatic operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

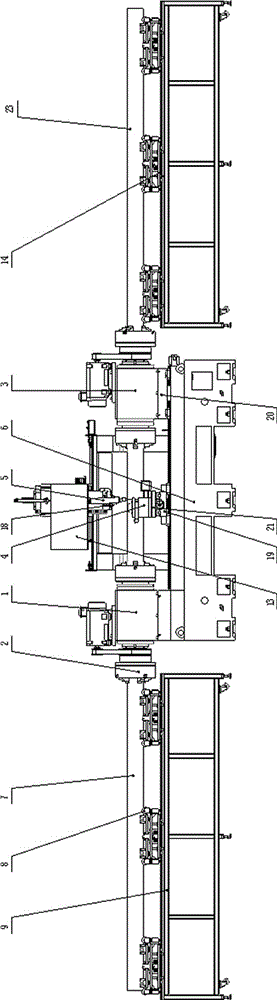

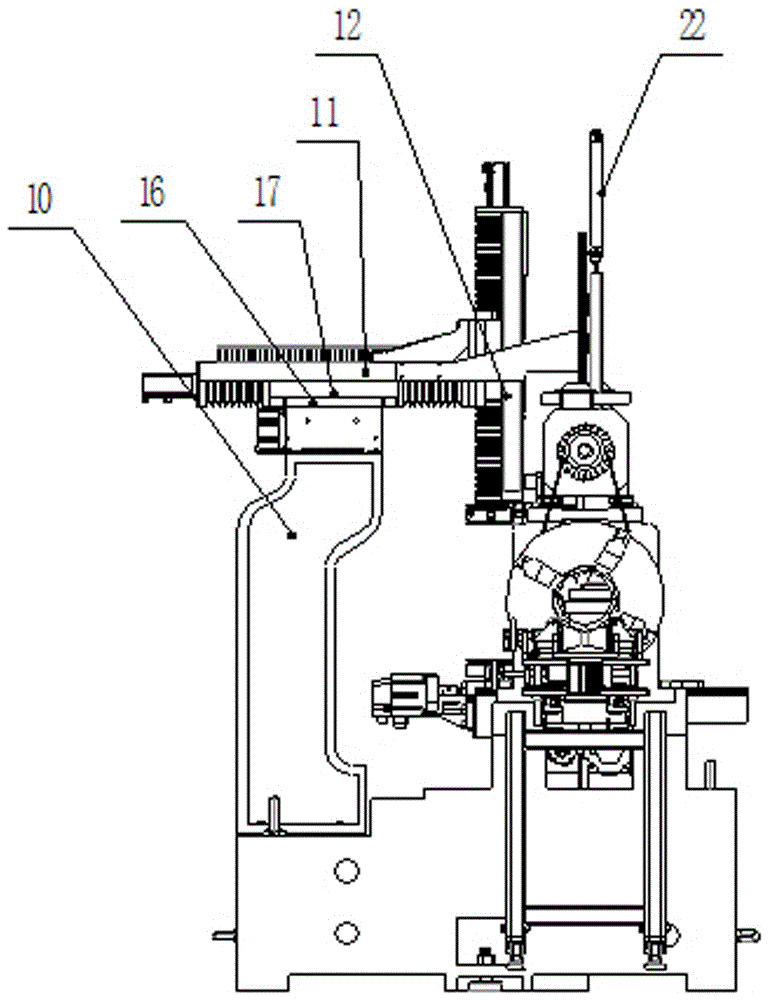

[0019] Such as figure 1 , figure 2 As shown, the fixed headstock 1 is fixedly installed on one end of the bed base 6, a chuck 2 is installed at the front and rear ends of the fixed headstock 1, and the movable headstock 3 is installed on the right end of the bed base 6 along with a sliding seat. 20. The sliding seat 20 is provided with a moving headstock 3, and a chuck is respectively installed at the front and rear ends of the moving headstock 3; the left conveying frame 9 and the right side of the bed base 6 are respectively provided with The right conveyor frame 14; the left conveyor frame 9 and the right conveyor frame 14 are provided with rollers 8; the fixed headstock 1 and the mobile spindle box 3 are clamped by the respective front and rear chucks and sent by the left conveyor frame 9 and the right conveyor frame 14 The left steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com