Resistance welding machine for pipeline engineering connection construction

A technology of resistance welding and pipeline engineering, applied in the direction of resistance welding equipment, welding equipment, welding equipment, etc., can solve the problems of welding position offset, pipeline support structure cooperation operation, inconvenient pipeline rotation processing, etc., to reduce friction and rotate quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

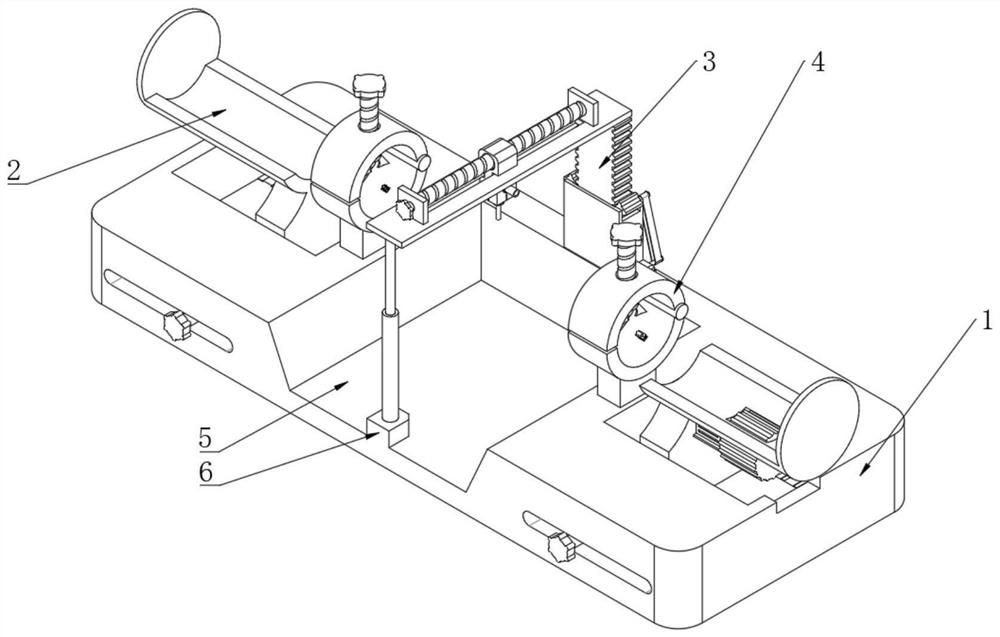

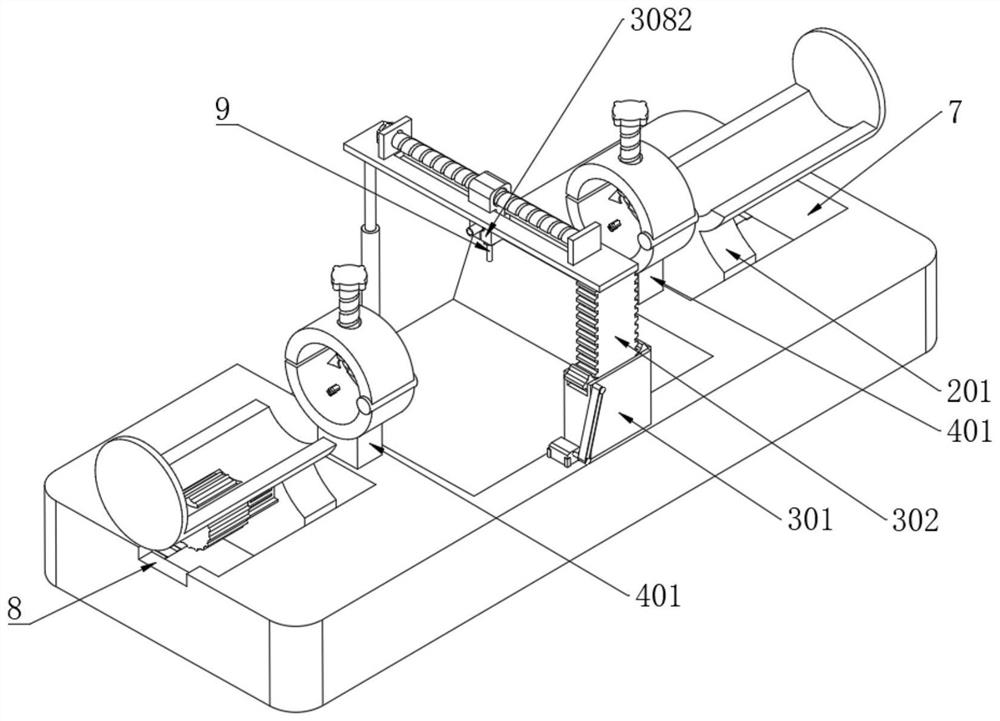

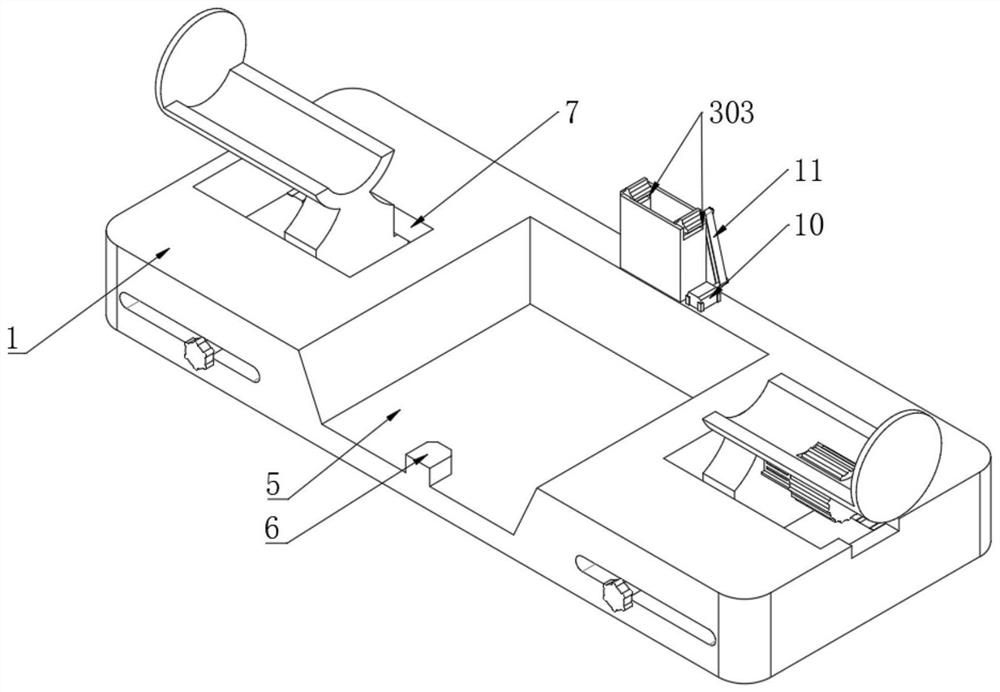

[0039] like Figure 1-13 As shown, a resistance welding machine for pipeline engineering connection construction includes an equipment base 1, and lateral penetration grooves 7 are respectively provided on both sides of the equipment base 1, and each lateral penetration groove 7 is below and located inside the equipment base 1 respectively There are matching sliding grooves 203, each matching sliding groove 203 is provided with a support assembly 2 inside, a waste collection groove 5 is opened in the middle of the equipment base 1, and the upper surface of the equipment base 1 located on one side of the waste collection groove 5 is integrally provided with an extension. Mounting block 6, a combination board 301 is fixedly installed on the upper surface of the equipment base 1 on the side away from the expansion mounting block 6, the second motor 10 is fixedly installed on one side of the combination board 301, and a machining center is installed between the combination board 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com