Clamping device for processing mushroom-shaped blade having Z-shaped blade shroud

A clamping device and blade technology, applied in clamping devices, positioning devices, manufacturing tools, etc., can solve the problems of inability to meet processing size requirements and large cumulative errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

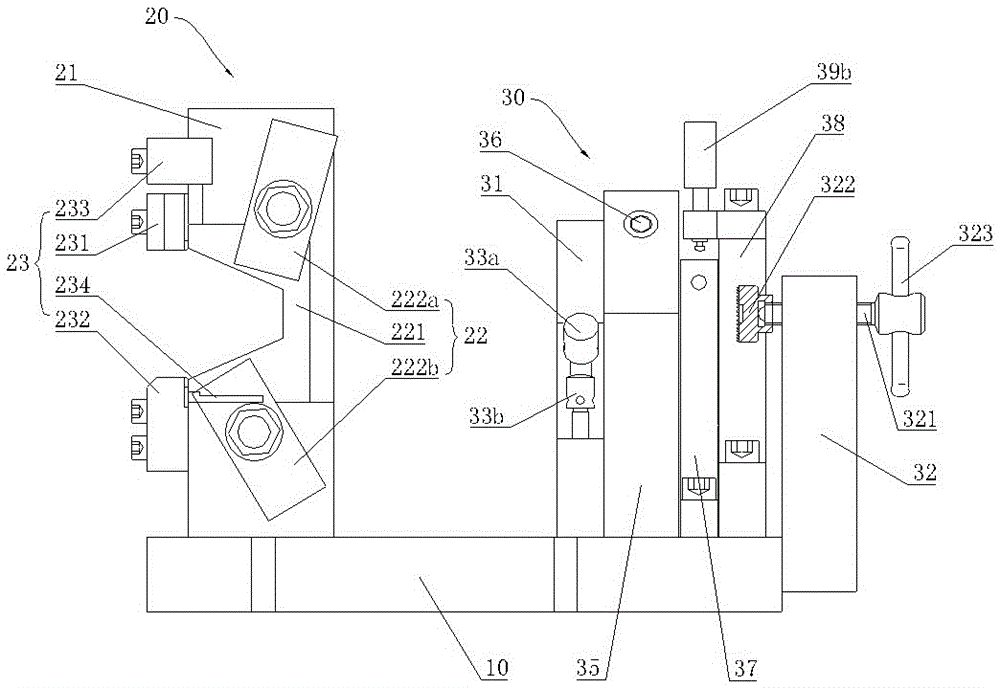

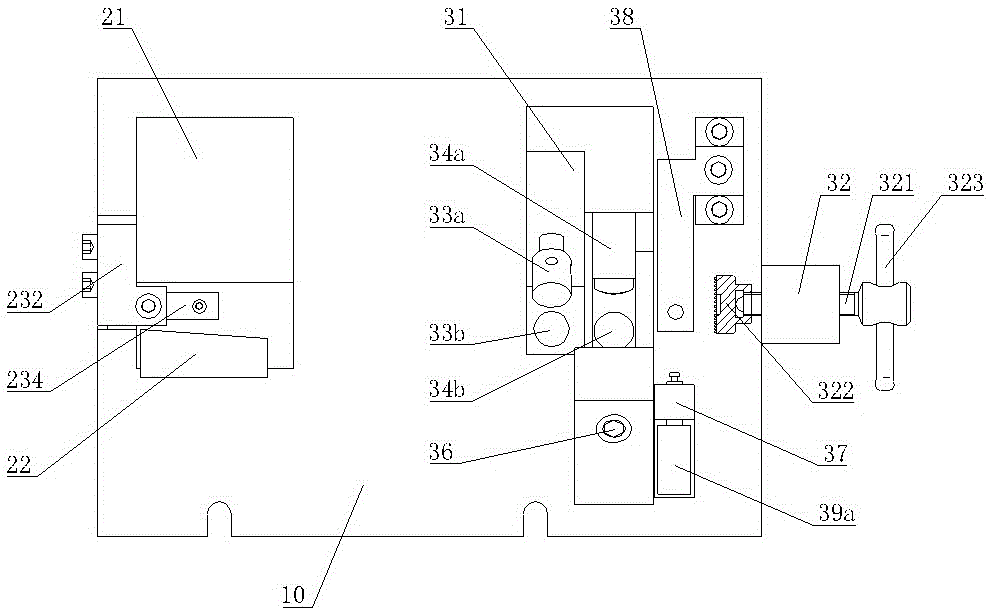

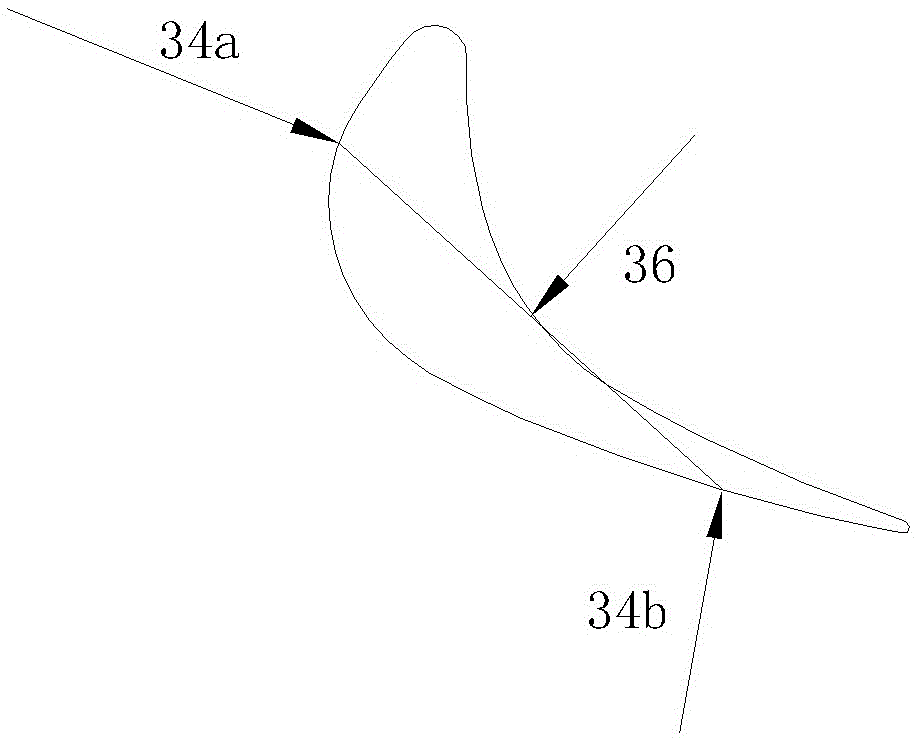

[0022] See figure 1 , figure 2 , the fixture device of the present invention includes a bottom plate 10, and the left and right lateral sides of the bottom plate 10 are respectively equipped with a blade root positioning and clamping assembly 20 and a blade crown positioning and clamping assembly 30, and the blade crown positioning and clamping assembly 30 includes a blade crown top tightening seat 32 and the blade crown positioning seat 31, the blade crown tight seat 32 is detachably installed on the lateral right end of the base plate 10, the blade crown positioning seat 31 is installed on the base plate 10 and is located at the lateral left end of the blade crown tight seat 32; A positioning concave groove is provided on the front side wall of the blade crown positioning seat 31, and the groove bottom surface 312 of the positioning groove and the front side groove wall 311 are respectively provided with support screws 33a, 33b, and the rear side groove wall 313 of the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com