Deep hole polishing machining device

A grinding and deep hole technology, which is applied in the direction of grinding/polishing safety devices, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem that the processing equipment is difficult to meet the requirements, and reduce microscopic unevenness degree, improve surface quality, and achieve the effect of inner hole shape and position tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

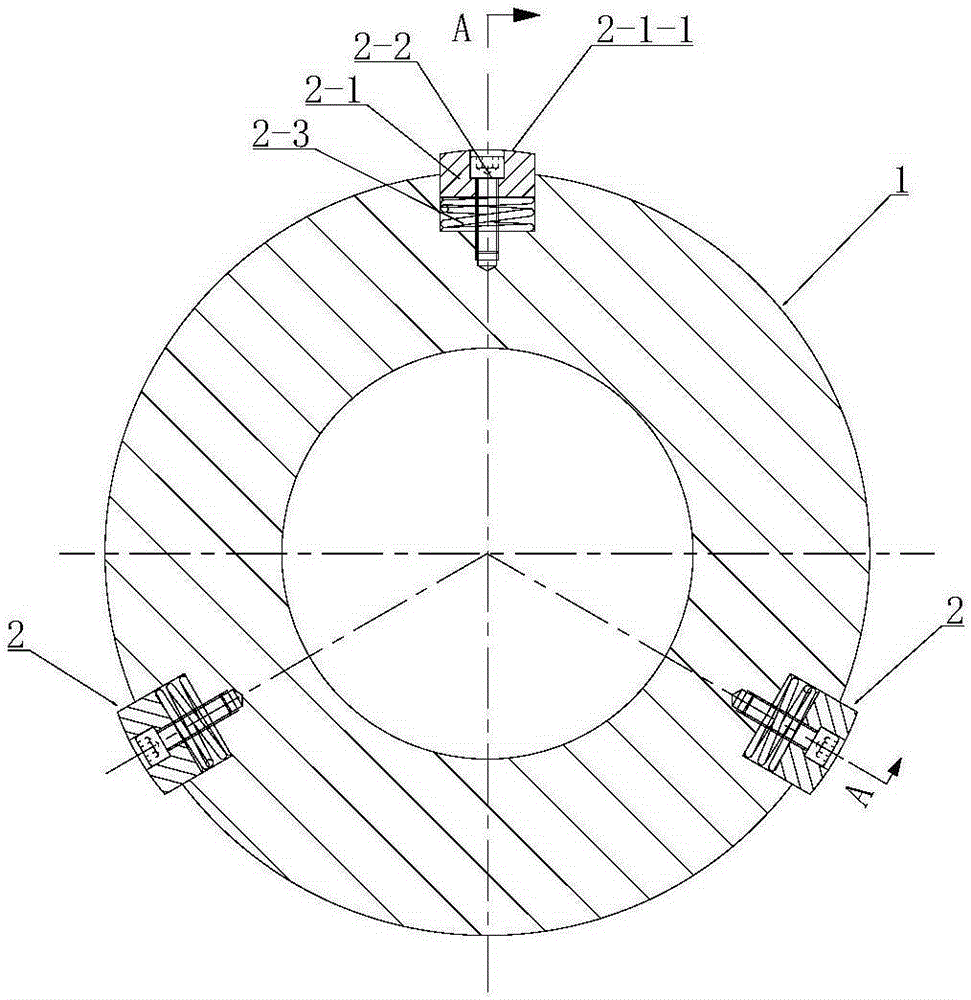

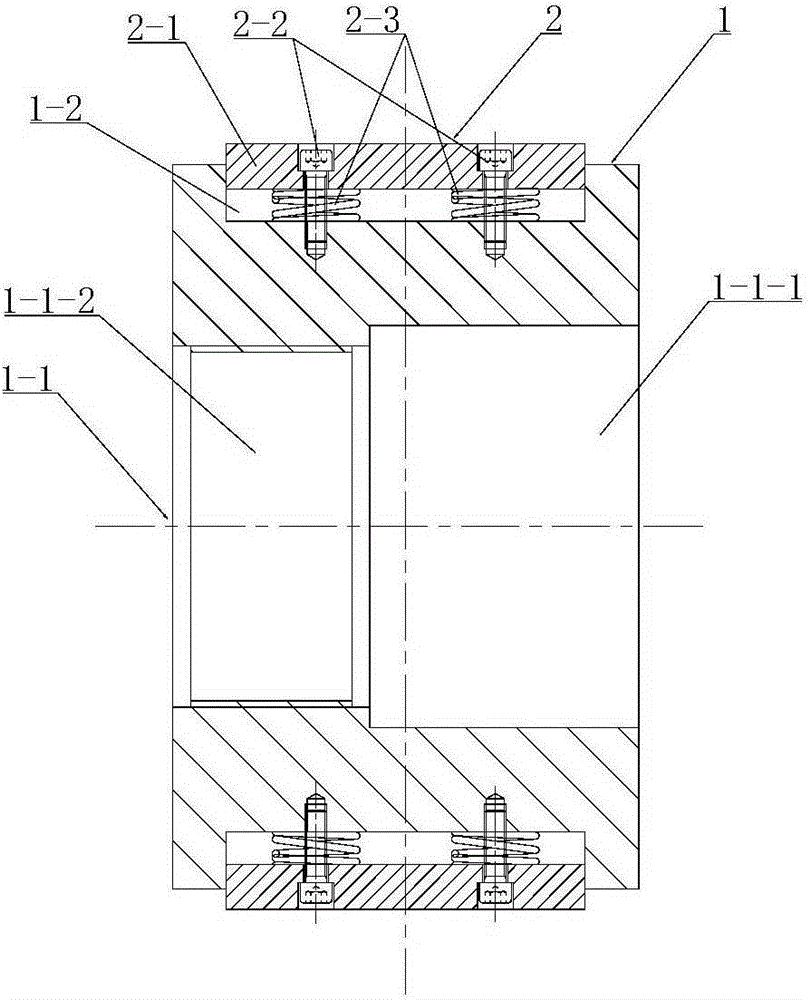

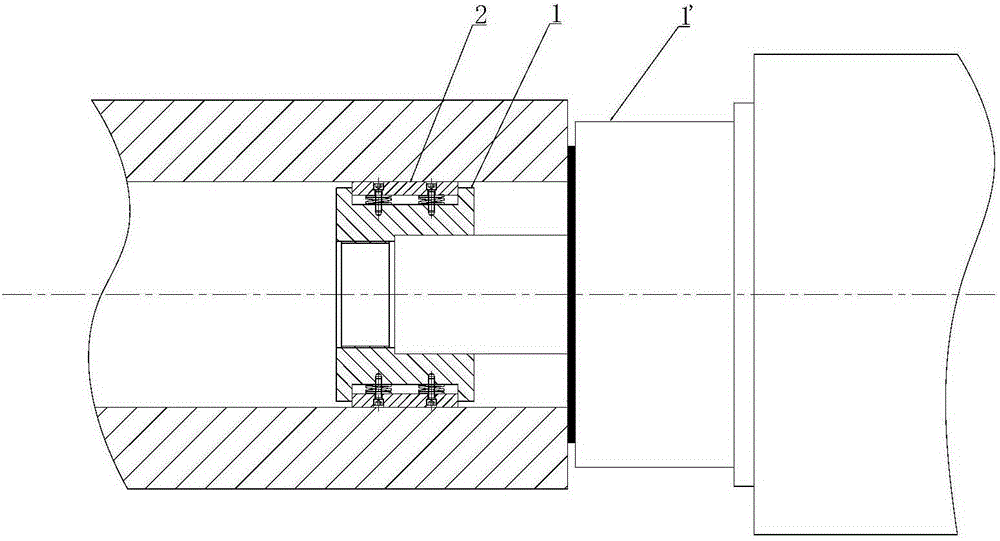

[0016] see Figure 1-3 , a deep hole grinding processing device is composed of the following parts:

[0017] It includes a disc-shaped cutter body 1, and a mounting hole 1-1 matched with the boring bar is provided in the center of the cutter body, specifically, it is fixedly connected with the boring bar through the mounting hole. Several installation grooves 1-2 are uniformly arranged along the circumferential direction on the outer surface of the cutter body.

[0018] It includes an array of grinding components 2, and the array of grinding components are installed in several mounting grooves one by one. Each group of grinding components includes a grinding block 2-1, the side shape of the grinding block is consistent with the side shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com