Novel oil type mold temperature controller device

A mold temperature machine and a new type of technology, applied in the field of new oil-type mold temperature machine devices, can solve the problem that the performance indicators of the mold temperature machine cannot reach the ideal state, cannot meet the needs of large-scale production, and the service life of the mold temperature machine is not long, etc. problems, to achieve the effect of improving service life, ensuring saturation without leakage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

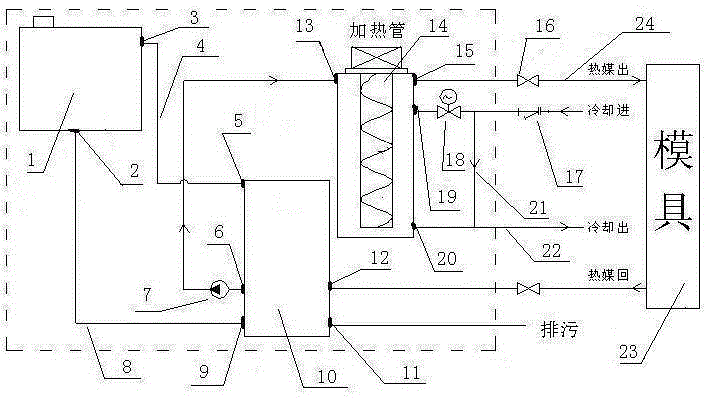

[0021] see figure 1 Shown, the present invention comprises oil tank 1, heating drum 14, cold circulation pipeline 22 and heat circulation pipeline 24, and the work flow of the present invention is:

[0022] 1) Correctly connect the pipeline, refuel into the fuel tank 1 through the fuel tank port, and the oil flows from the fuel tank outlet 2 of the fuel tank 1 through the oil inlet pipe 8 to the oil return drum inlet 9 at the bottom of the oil return drum 10, and the oil returns to the oil drum The gas in 10 enters the air inlet 3 of the oil tank 1 through the air outlet 5 through the exhaust pipe 4, and is discharged from the top fuel tank port of the oil tank 1, and the oil returned to the oil tank 10 can also pass through the oil outlet 6 of the oil return tank through the circulation pump 7 enters the heating barrel 14 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com