Automotive suspension ball structure with high interference fit degree

A ball head, tight fitting technology, applied in steering mechanism, vehicle parts, steering rods, etc., can solve the problem of affecting the steering stability of steering gear and steering wheel transmission, the tight fitting degree does not meet strict requirements, and cannot reduce vibration force, etc. problems, to avoid transmission stability, avoid tight fit changes, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

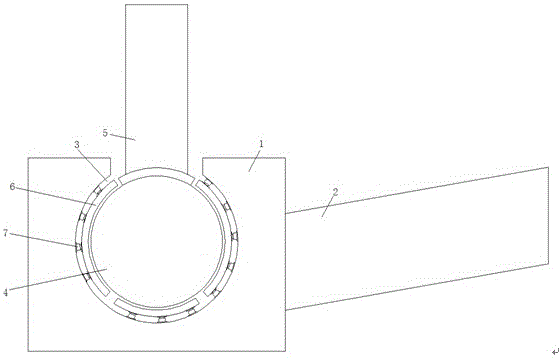

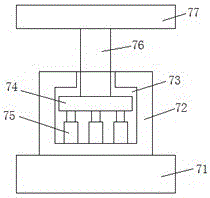

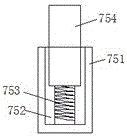

[0019] refer to Figure 1-4 , this embodiment proposes a car suspension ball structure with high tightness, including a ball head seat 1 and a connecting arm 2 welded to one side of the ball head seat 1, and a ball head groove is opened on the top of the ball head seat 1 3. A ball head 4 is movably installed in the ball head groove 3, a ball head arm 5 is welded on the top of the ball head 4, and wear-resistant plates 6 located in the ball head groove 3 are provided on both sides and below the ball head 4 The side of the wear-resistant plate 6 close to the ball head 4 is slidingly connected with the ball head 4, and the side of the wear-resistant plate 6 away from the ball head 4 is welded with one end of the connecting mechanism 7, and the other end of the connecting mechanism 7 is welded to the ball groove On the inner wall of 3, the connection mechanism 7 includes a bottom plate 71 welded on the inner wall of the ball groove 3, and the side of the bottom plate 71 close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com