Mud scraper of track harvester

A harvester and mud scraper technology, applied in the field of mechanical parts, can solve problems such as cumbersome cleaning, blockage of track operation, and influence on normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

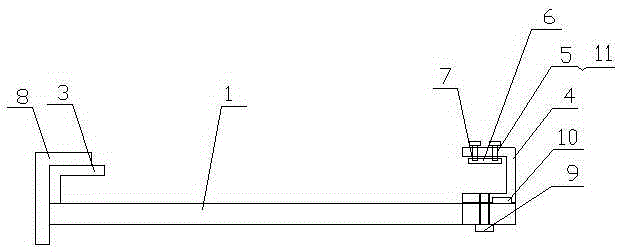

[0008] Such as figure 1 As shown, the crawler harvester mud scraping device includes a main mounting plate 1 for cooperating with short ribs on the track surface, a rectangular through hole 2 is arranged in the middle of the main mounting plate 1, and the main mounting plate 1 passes through 2 sets of rectangular through holes. It is placed on the short convex rib located in the middle of the track surface, and is fixedly connected to the L-shaped hook plate 3 at one end of the length direction of the main mounting plate 1. The inner corner of the L-shaped hook plate 3 is facing the main mounting plate 1. The other end is detachably connected to a U-shaped fixing part 4, the opening of the U-shaped fixing part 4 faces the L-shaped hook plate 3, and the U-shaped fixing part 4 and the L-shaped hook plate 3 are arranged on the same side of the main mounting plate 1; U-shaped One side wall of the fixing part 4 is detachably fixed on the main mounting plate 1, and at least two scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com