A logistics delivery robot

A robot and logistics technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as unstable center of gravity, easy stagnation on the road, accidents of robots, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] It should be noted in advance that the location word term specified in the description of the present invention takes the location of the conveyor belt as the front of the robot.

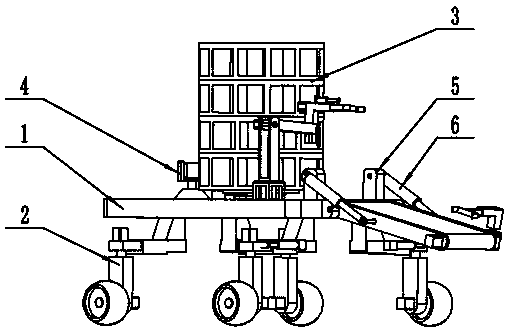

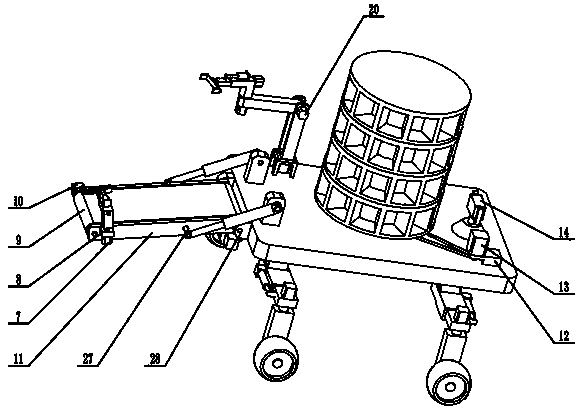

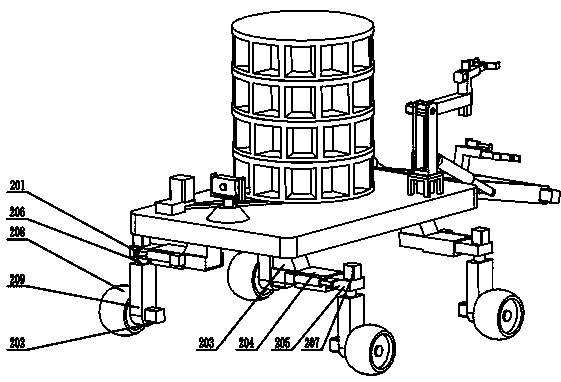

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, a logistics delivery robot includes a platform 1, four walking structures 2, four storage baskets 3, a pan platform 4, two first electric cylinder supports 5, two first electric cylinders 6, a second electric cylinder A servo motor 7, a first servo motor seat 8, a transmission belt 9, a second servo motor 10, two conveyor belt supports 11, a third servo motor seat 12, a third servo motor 13, a camera 14, a mechanical arm seat 15. A fourth servo motor 16, a mechanical arm forearm 17, a fifth servo motor 18, a mechanical arm rear arm 19, a sixth servo motor 20, a seventh servo motor 21, a first telescopic sleeve 22. A first telescopic rod 23, a second electric cylinder 24, a third elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com