Patents

Literature

41results about How to "Sliding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

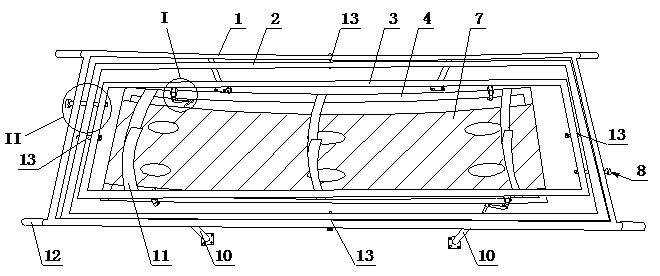

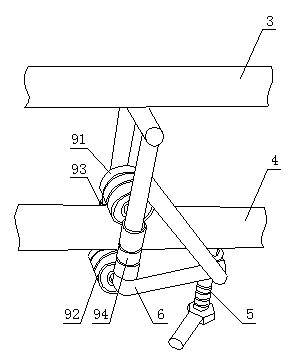

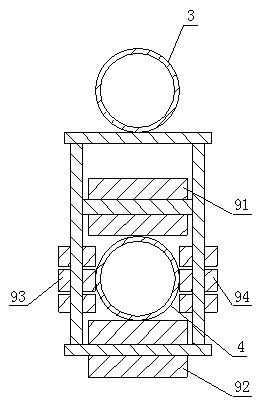

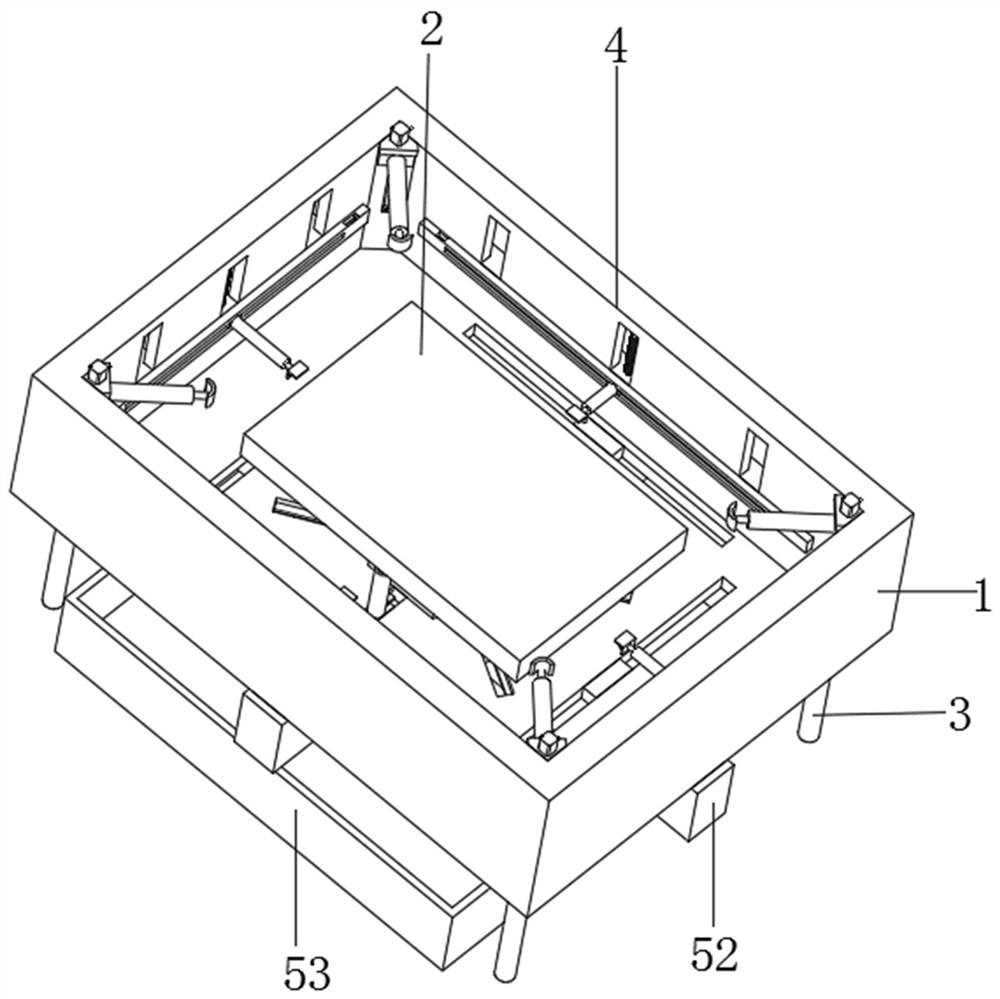

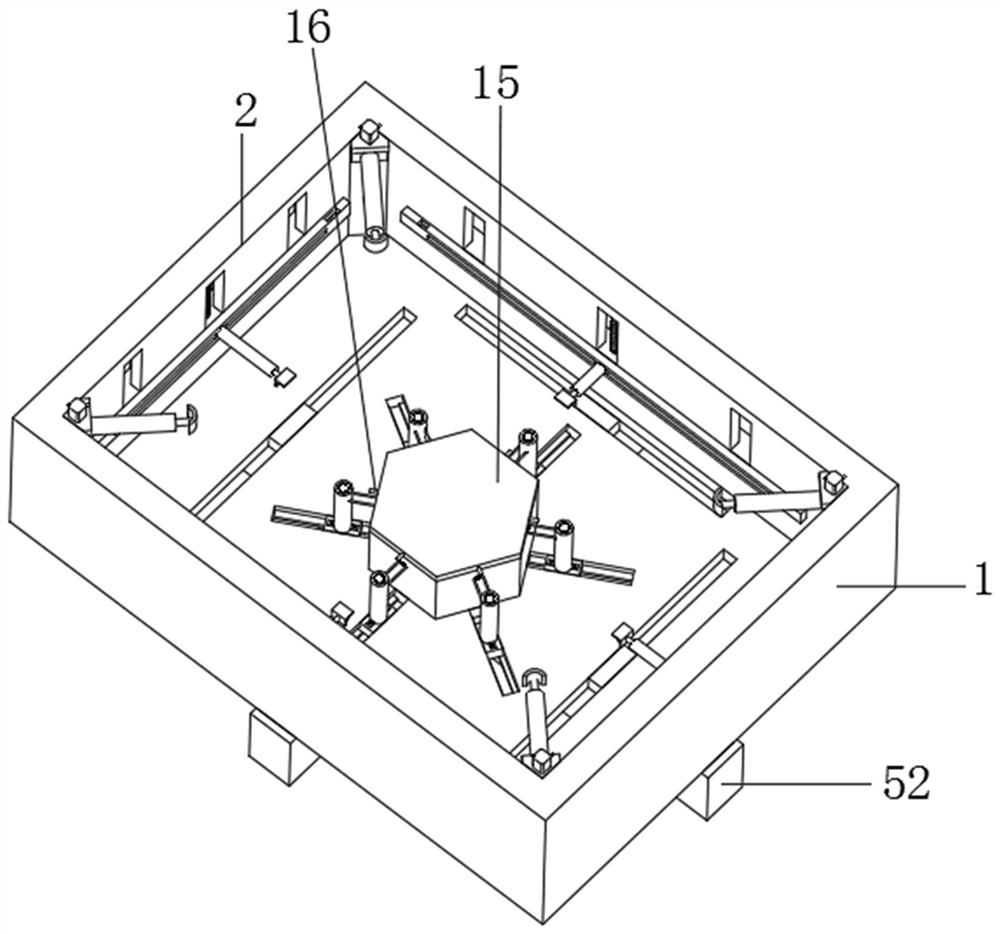

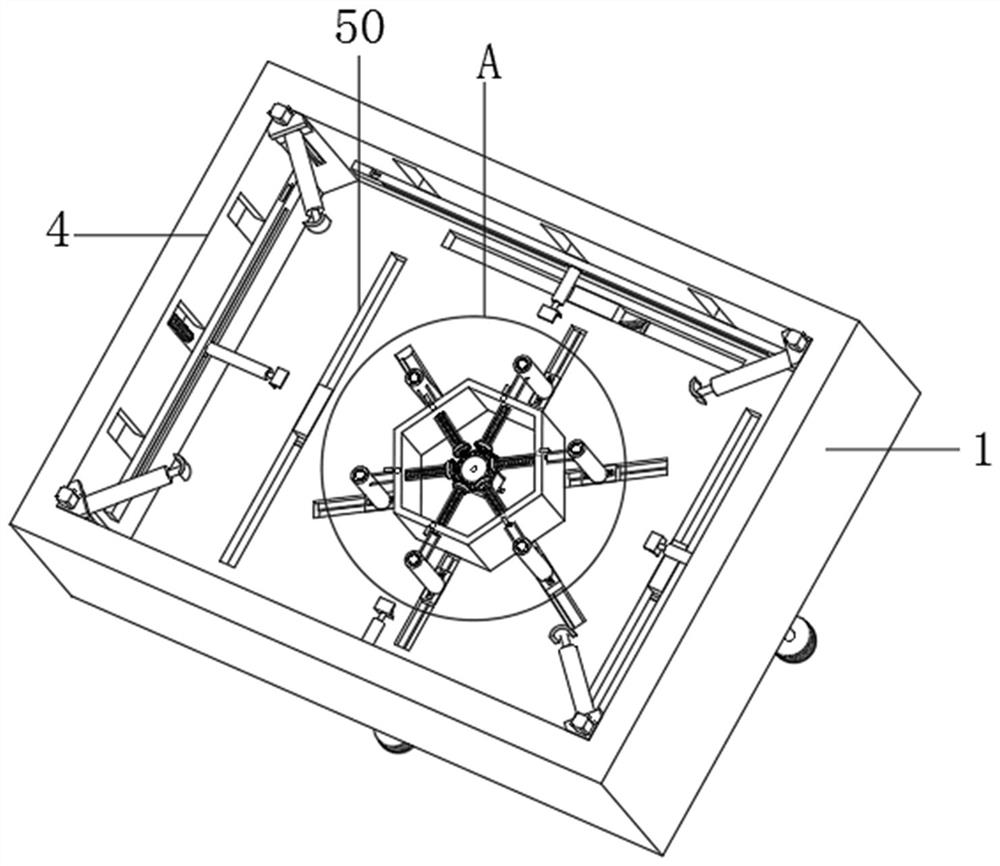

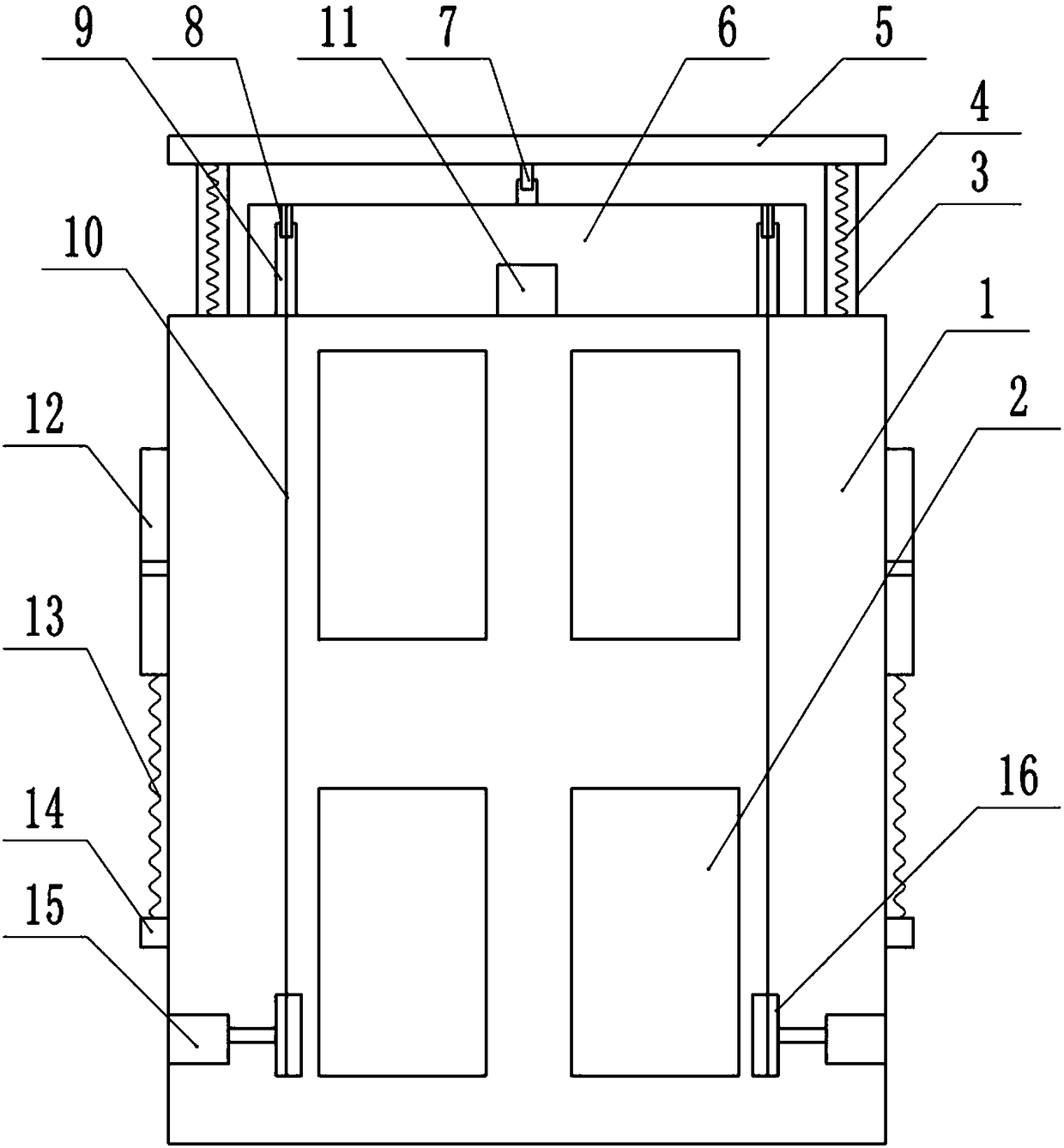

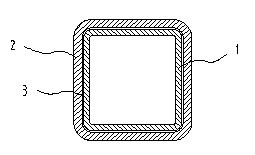

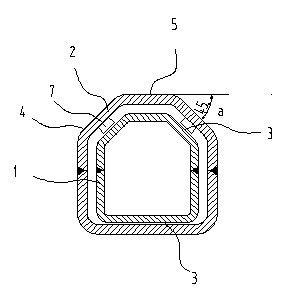

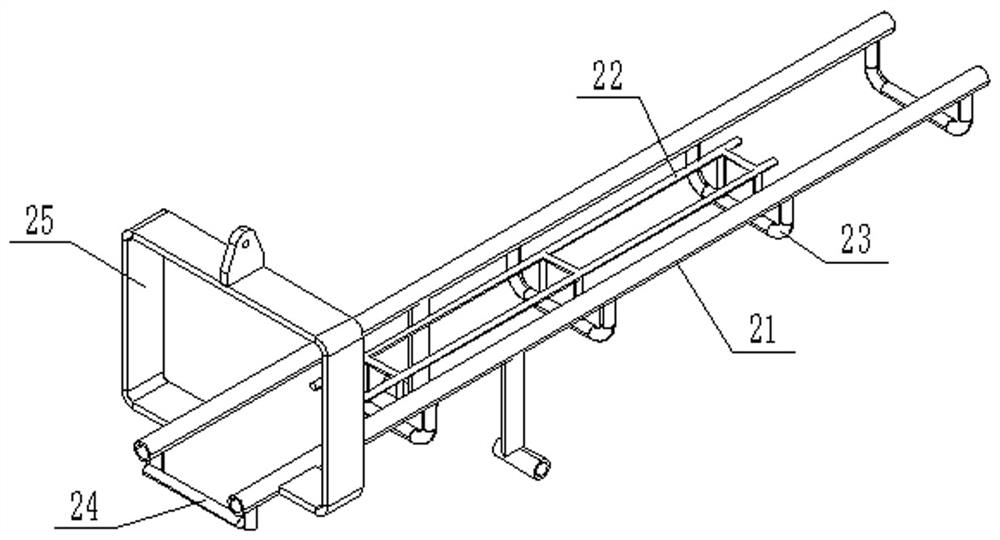

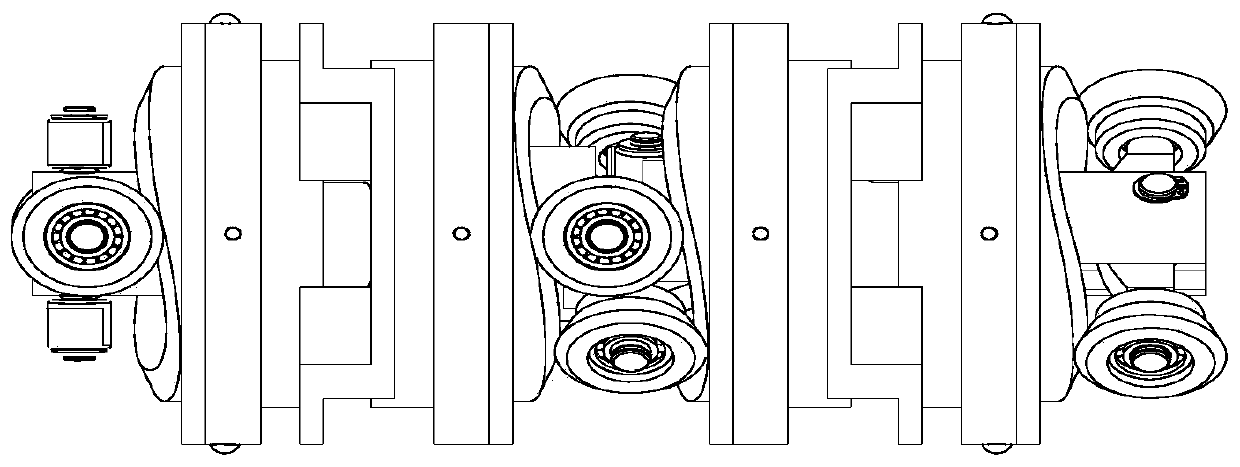

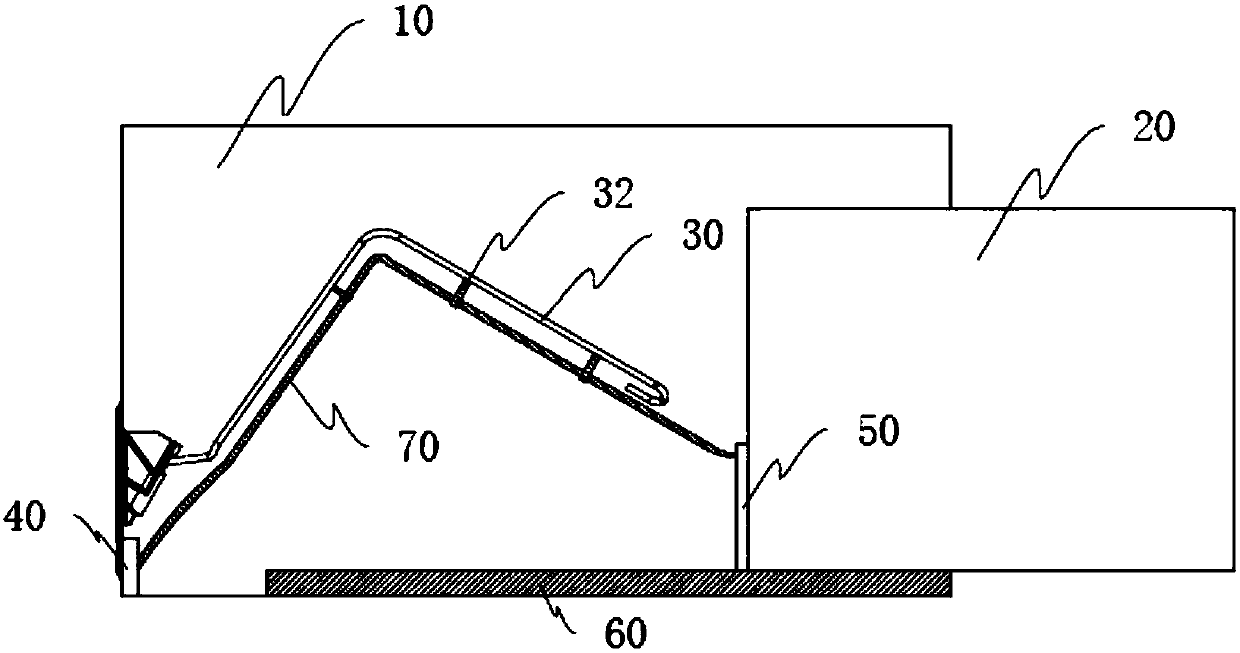

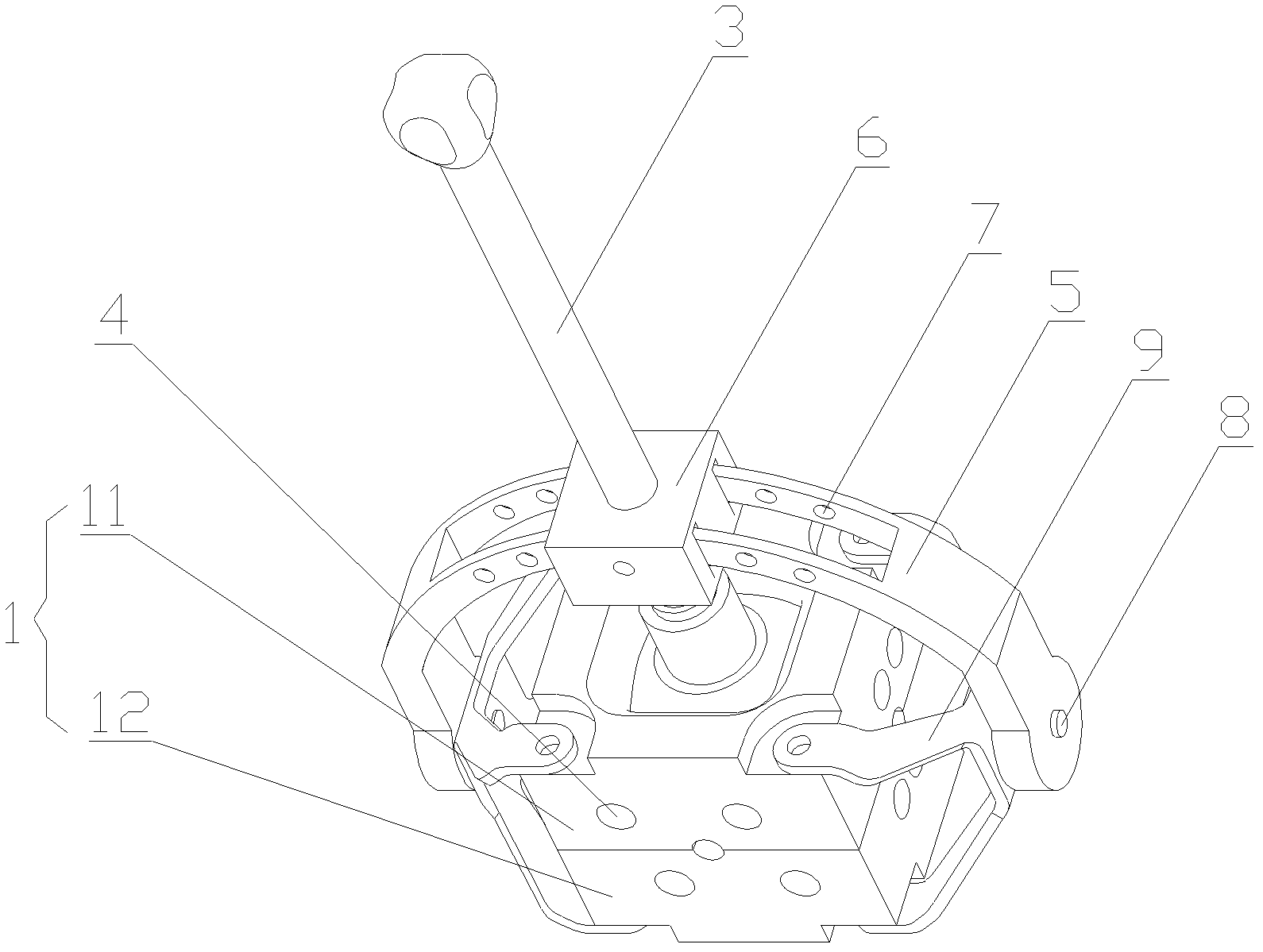

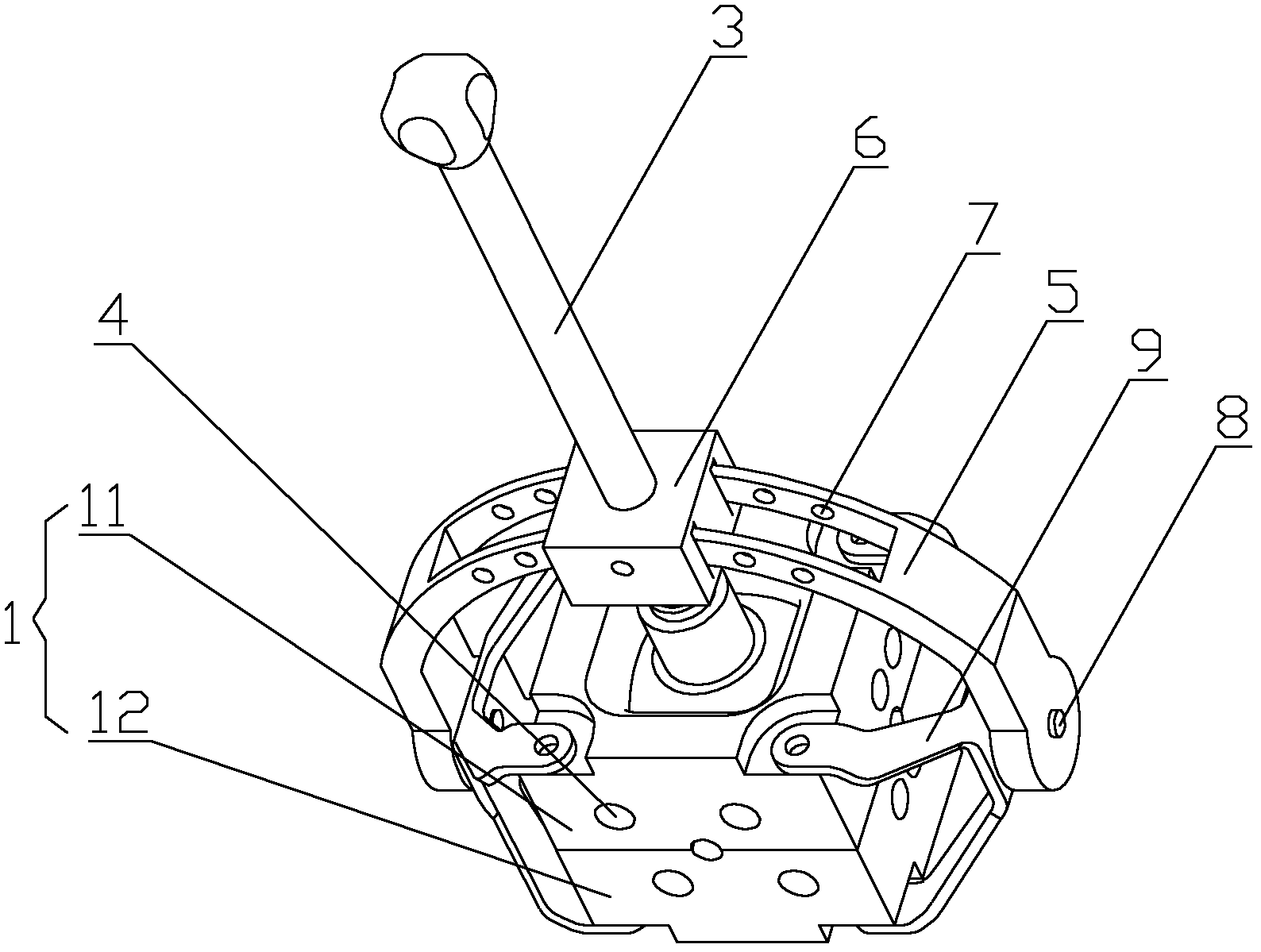

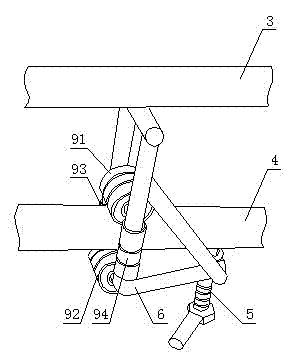

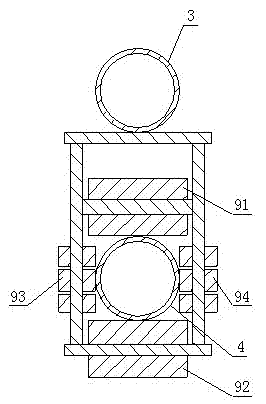

Self-balancing stretcher

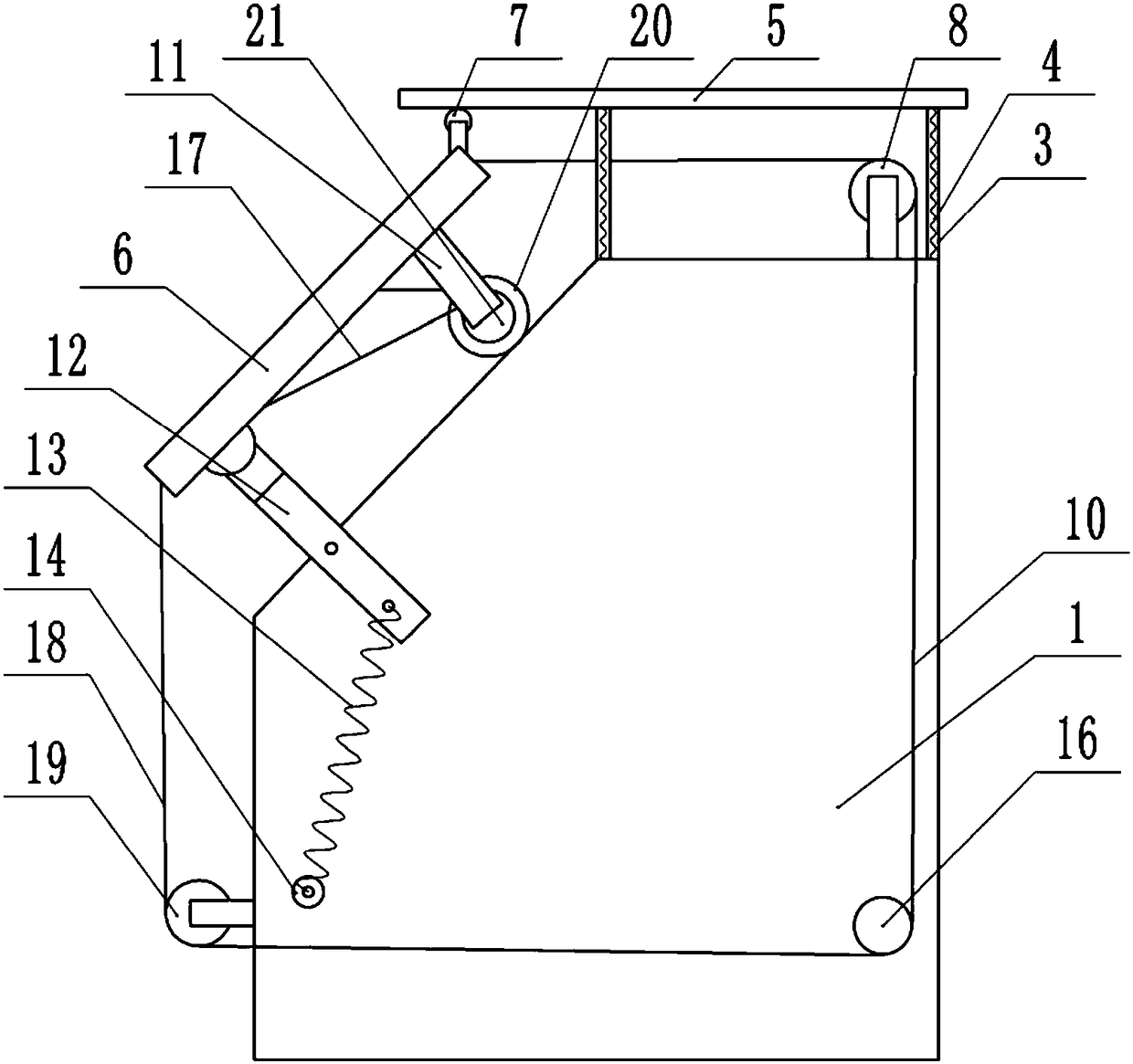

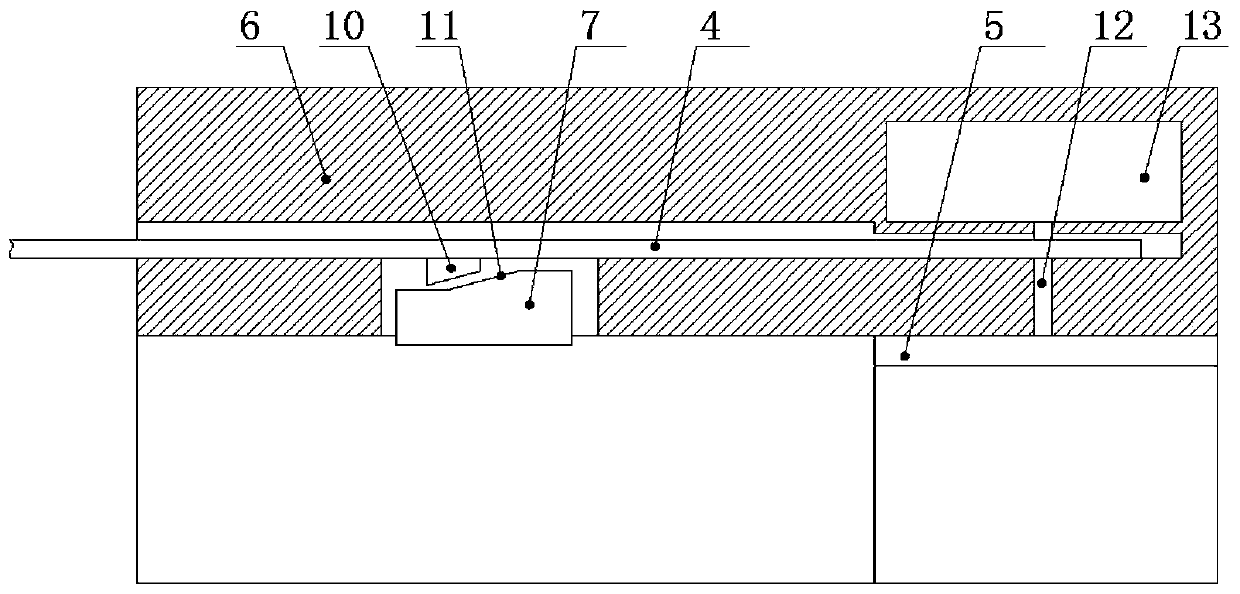

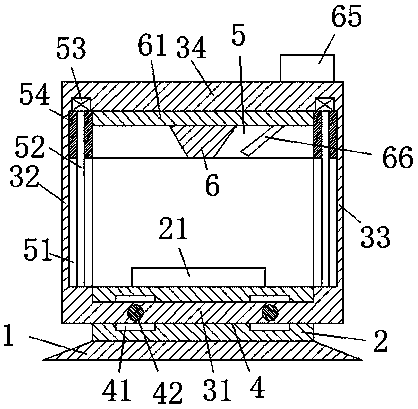

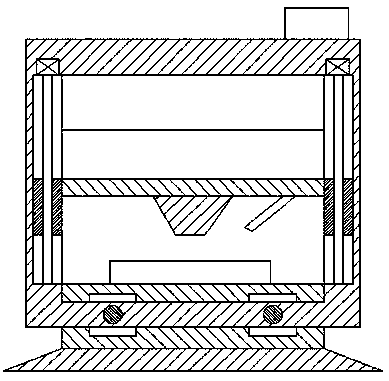

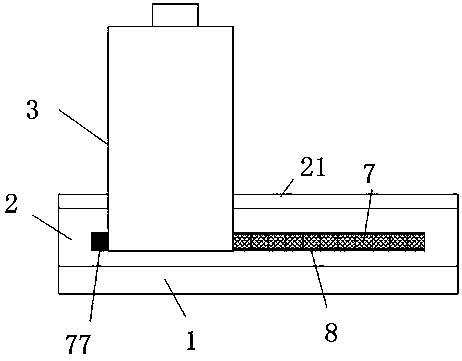

The invention relates to a self-balancing stretcher. The stretcher comprises a first framework layer, wherein a second framework layer and a third framework layer are arranged on the inner side of the first framework layer in turn; two support rods in a length direction or a width direction of the second framework layer are rotatably connected with two support rods on the first framework layer respectively, and the other two support rods on the second framework layer are rotatably connected with two support rods on a third framework layer; the connection joints of the first framework layer, the second framework layer and the third framework layer are positioned in the center of the support rods to which the connection joints belong respectively; a sliding mechanism is arranged on two support rods in the length direction of the third framework layer respectively; the third framework layer is in sliding connection with a fourth framework layer by the sliding mechanism; two support rods on the fourth framework layer which are connected with the third framework layer are arc-shaped; fastening bolts are arranged on the sliding mechanism; and the inner side of the fourth framework layer is connected with a bed surface. The stretcher of the invention has the advantages of high vibration damping performance, capacity of automatically adjusting the balance, simple structure, convenient and flexible use and low cost.

Owner:CHONGQING UNIV OF TECH

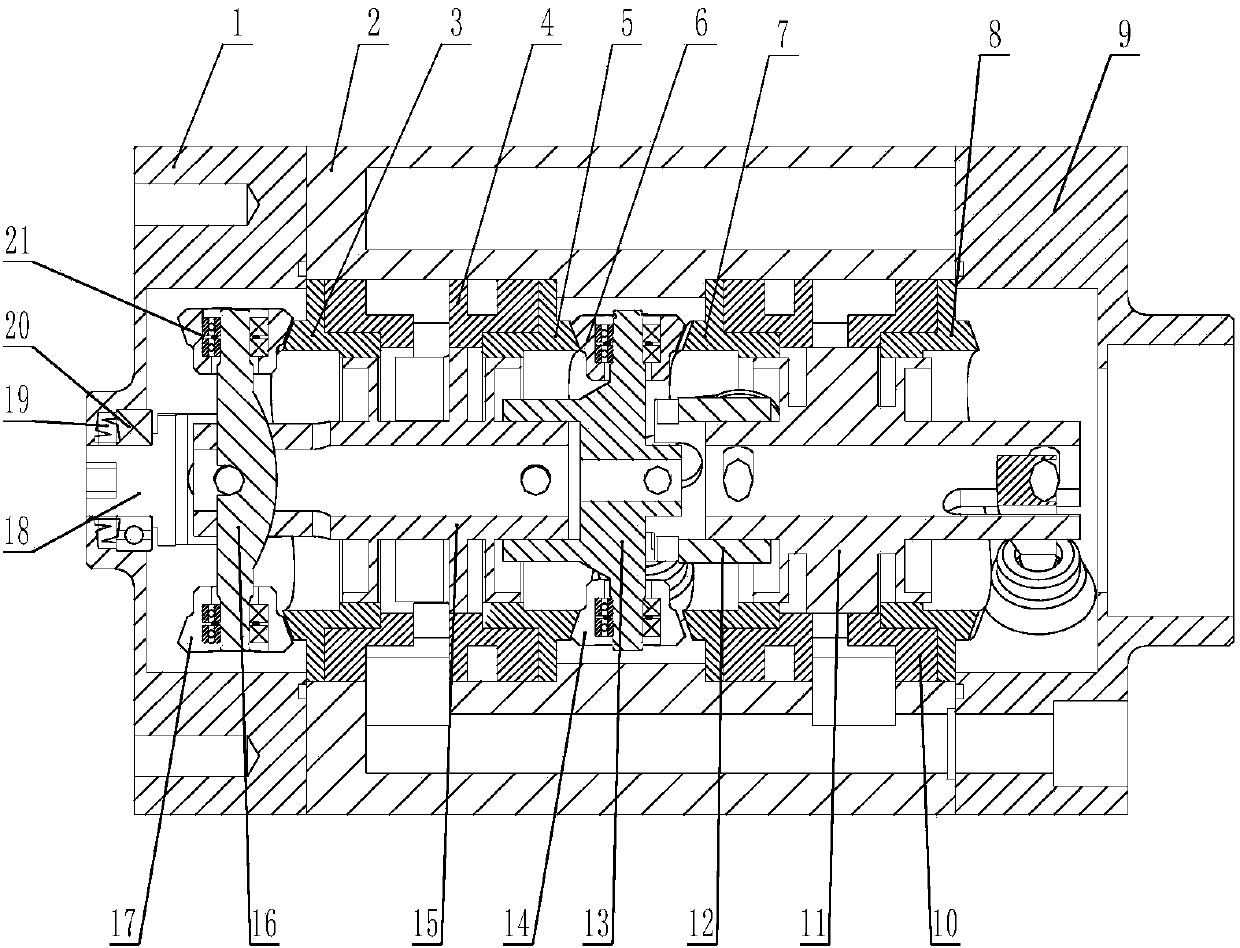

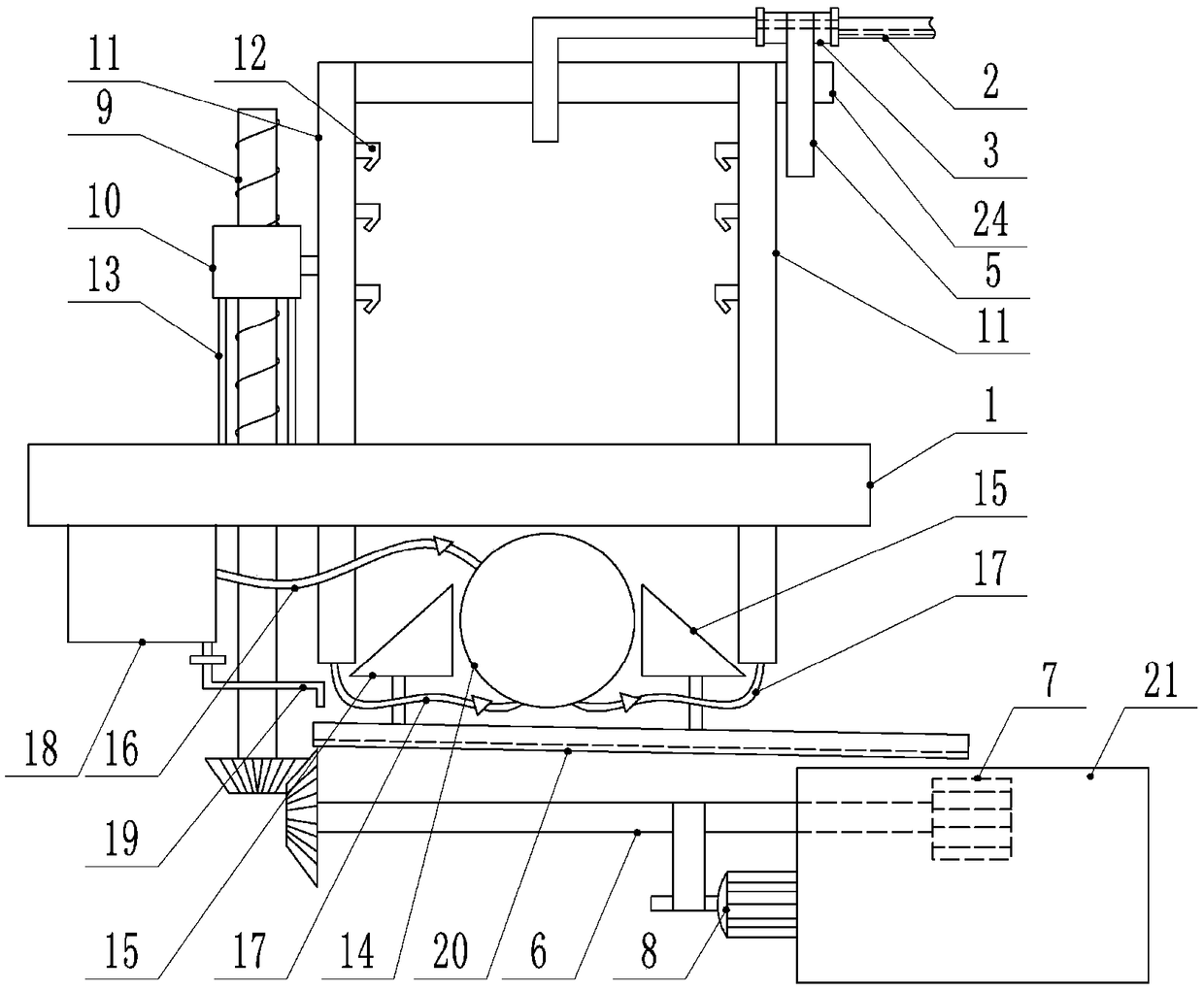

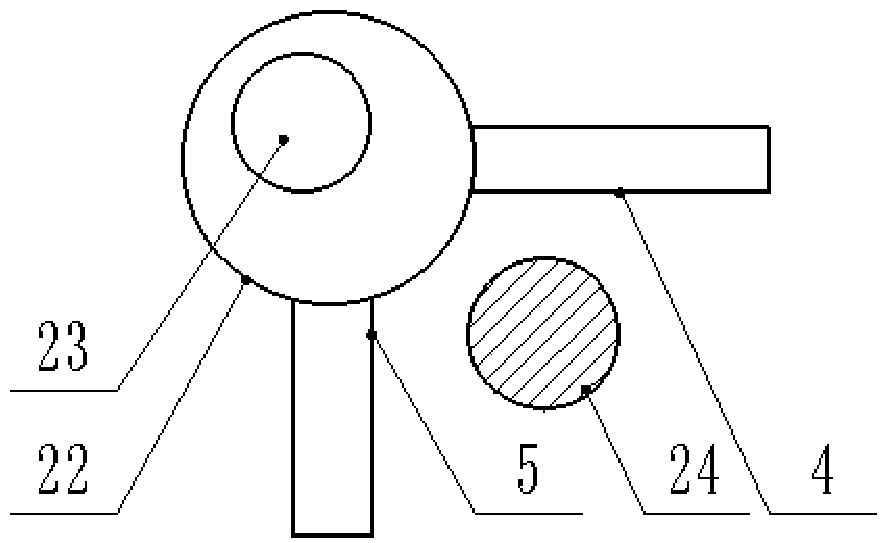

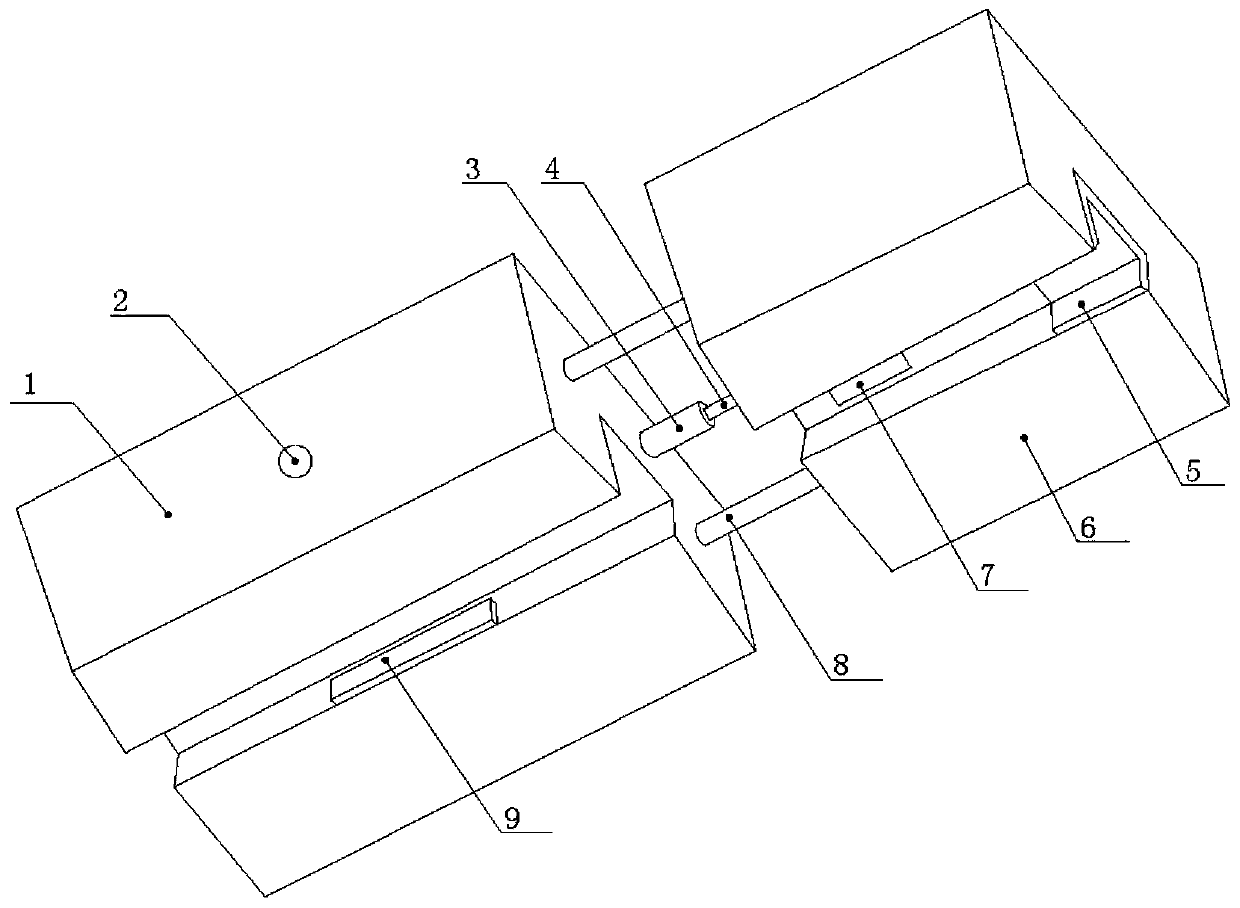

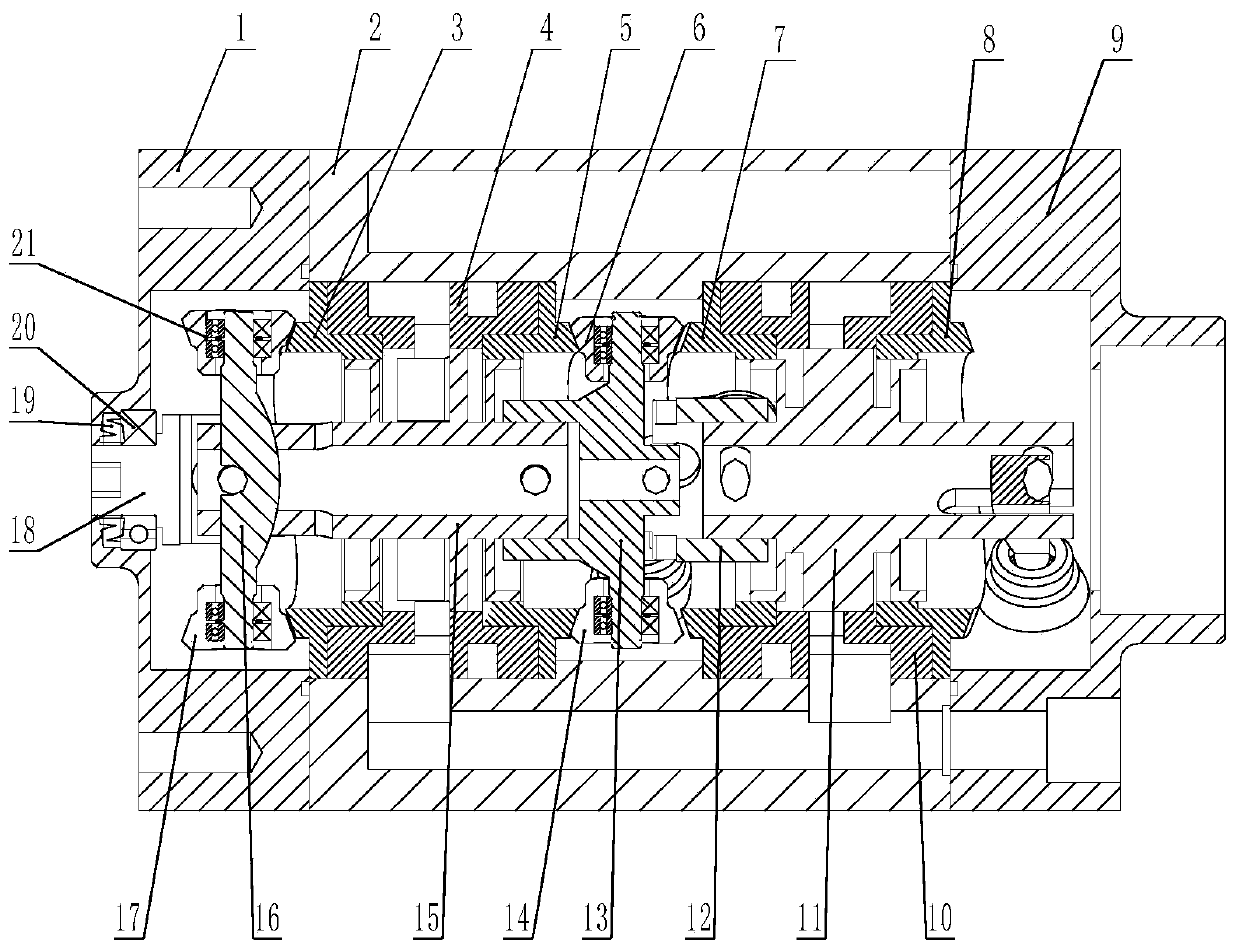

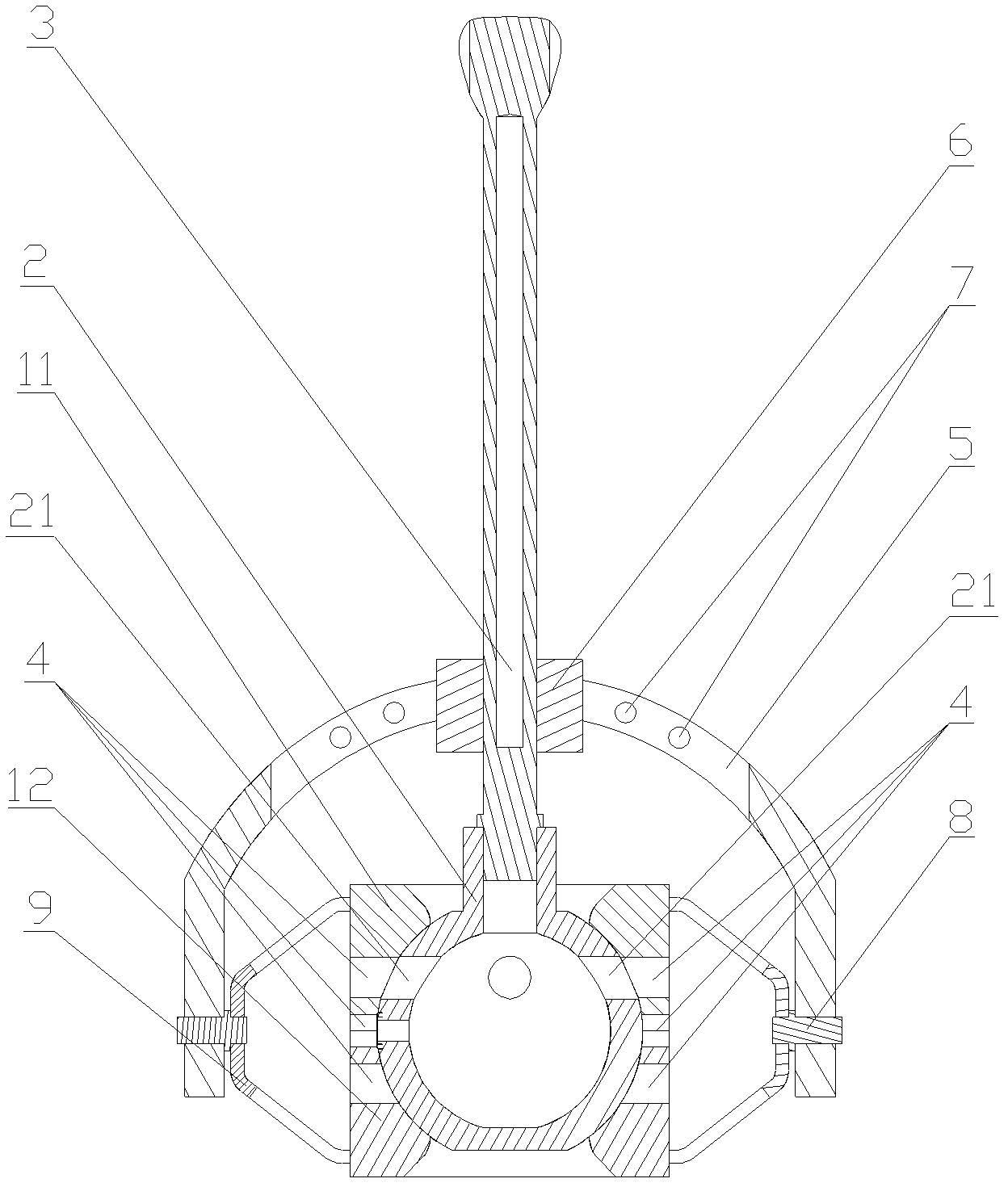

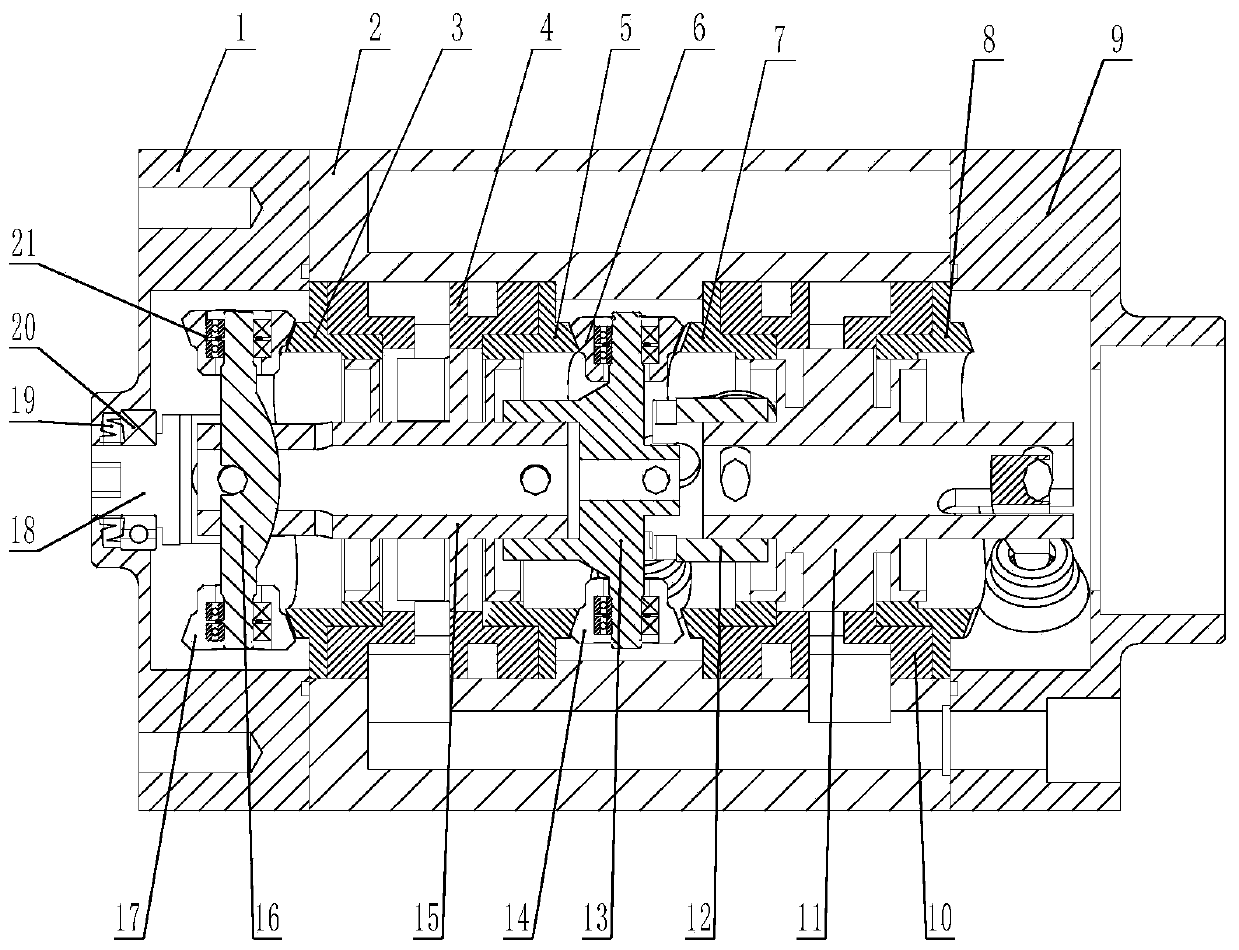

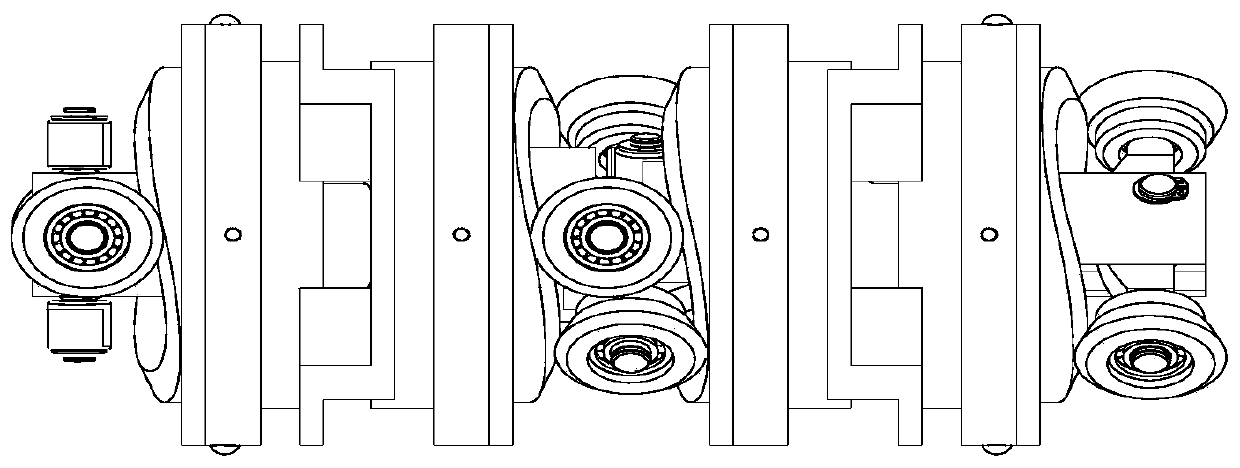

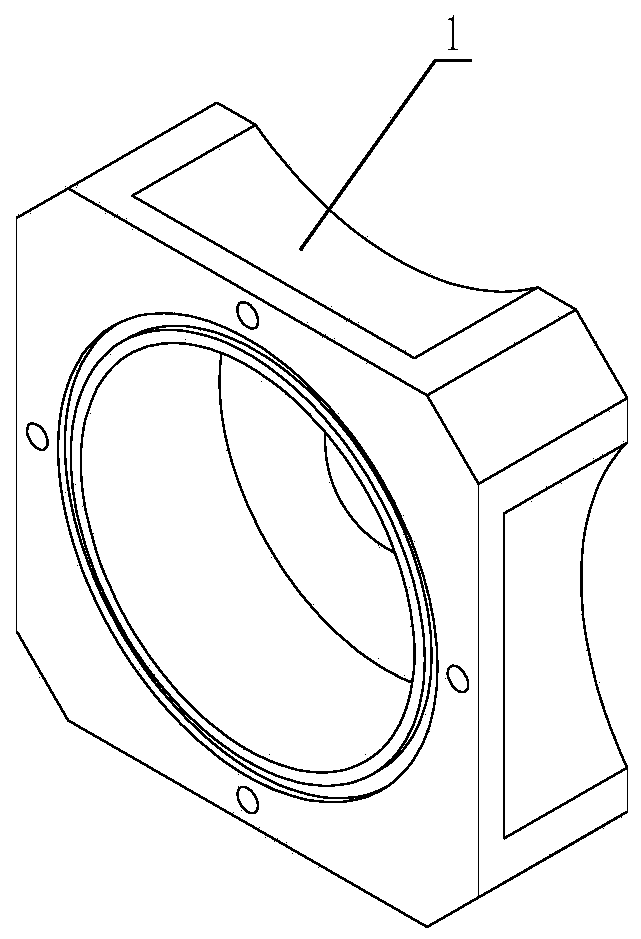

Floating type two-dimensional double-piston pump

ActiveCN107781125AReduce friction lossEliminate flow pulsationPositive displacement pump componentsPiston pumpsPlunger pumpCylinder block

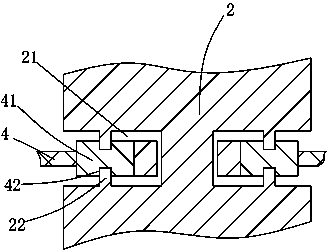

The invention discloses a floating type two-dimensional double-piston pump which comprises a pump. An oil suction opening and an oil drain opening are formed in the pump, a pump unit is arranged in the pump and comprises two cylinders, the two cylinders are fixed into the pump and are arranged in the left-right directions, and two pistons are arranged in the two cylinders and are in linkage with each other; the central axes of the cylinders coincide with the central axes of the pistons, movement components are arranged at two ends of each piston and are used for driving the piston to axially move to change the volume of a working chamber, and piston movement driving directions of the corresponding movement components at the two ends of each piston are opposite to each other; each cylinder,the corresponding piston and the corresponding movement components on two sides of the piston form a portion of the floating type two-dimensional double-piston pump, an upper portion of the floatingtype two-dimensional double-piston pump is close to a front end cover, and a lower portion of the floating type two-dimensional double-piston pump is close to a rear end cover. The floating type two-dimensional double-piston pump has the advantages that oil distribution disc structures of the traditional peripheral plunger pumps are replaced with rotary and slide double-degree-of-freedom structures of the pistons, and accordingly the floating type two-dimensional double-piston pump has continuous oil suction and drain functions; the floating type two-dimensional double-piston pump is in doublemodes, reciprocating movement is carried out by 4 times whenever each piston rotates by a circle, and oil can be sucked and drained by 16 times and are increased by 4 times as compared with single-piston pumps.

Owner:ZHEJIANG UNIV OF TECH

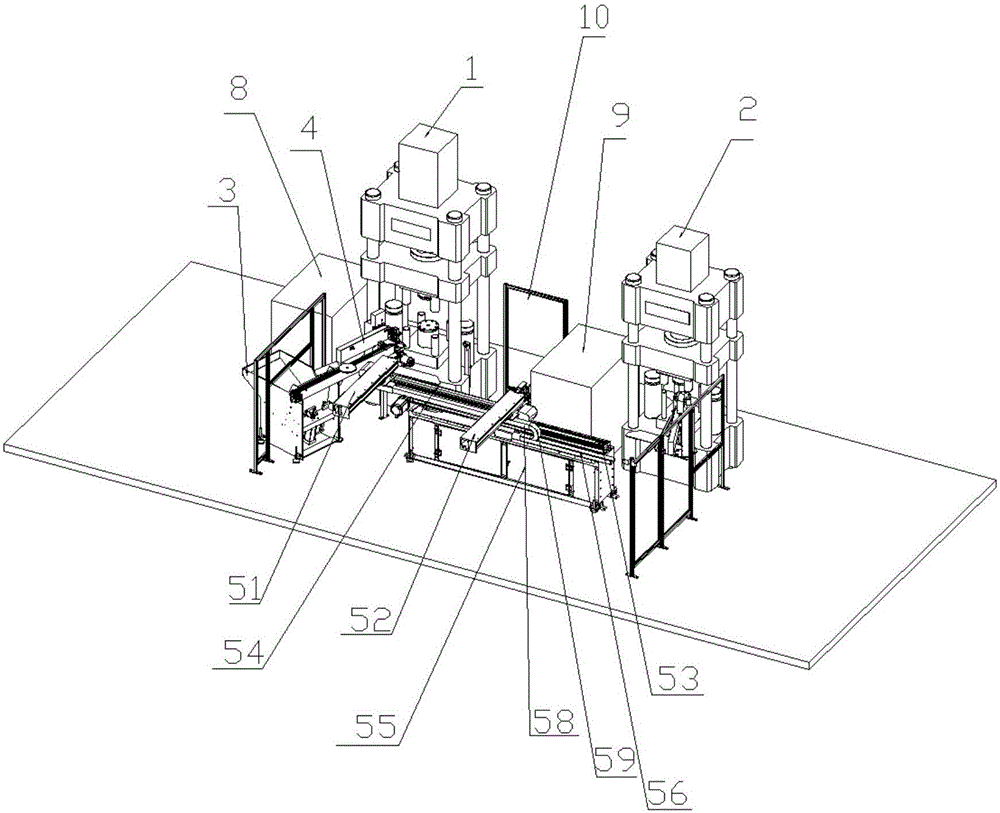

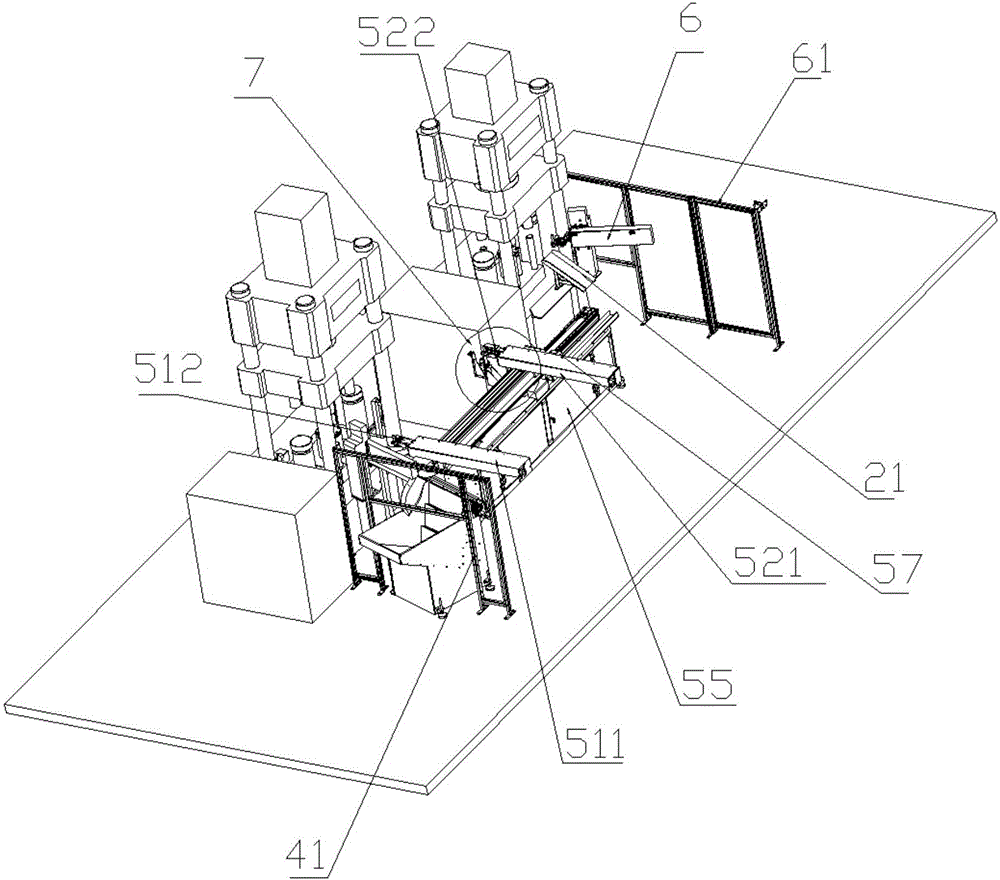

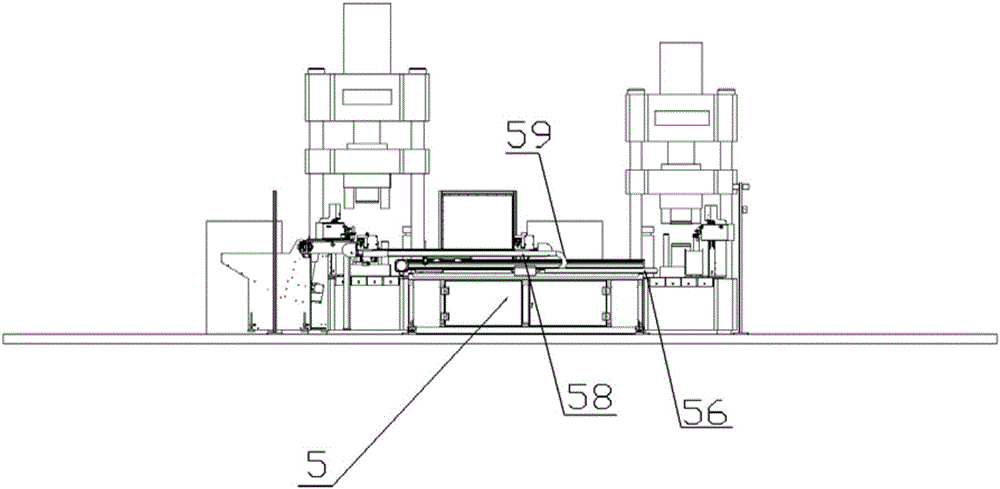

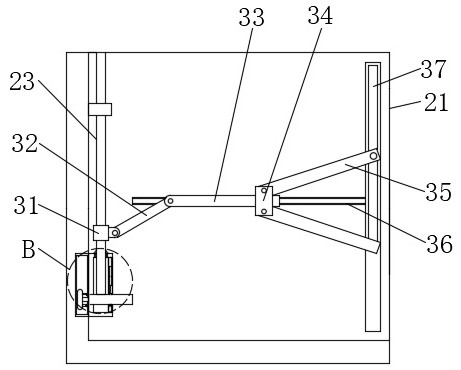

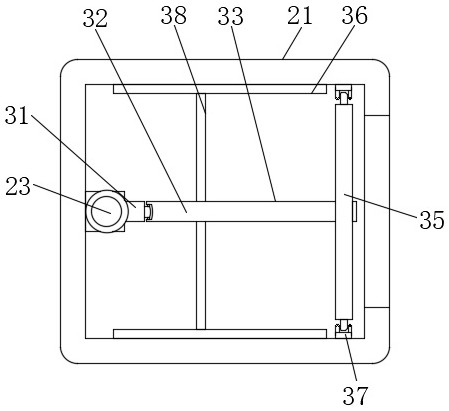

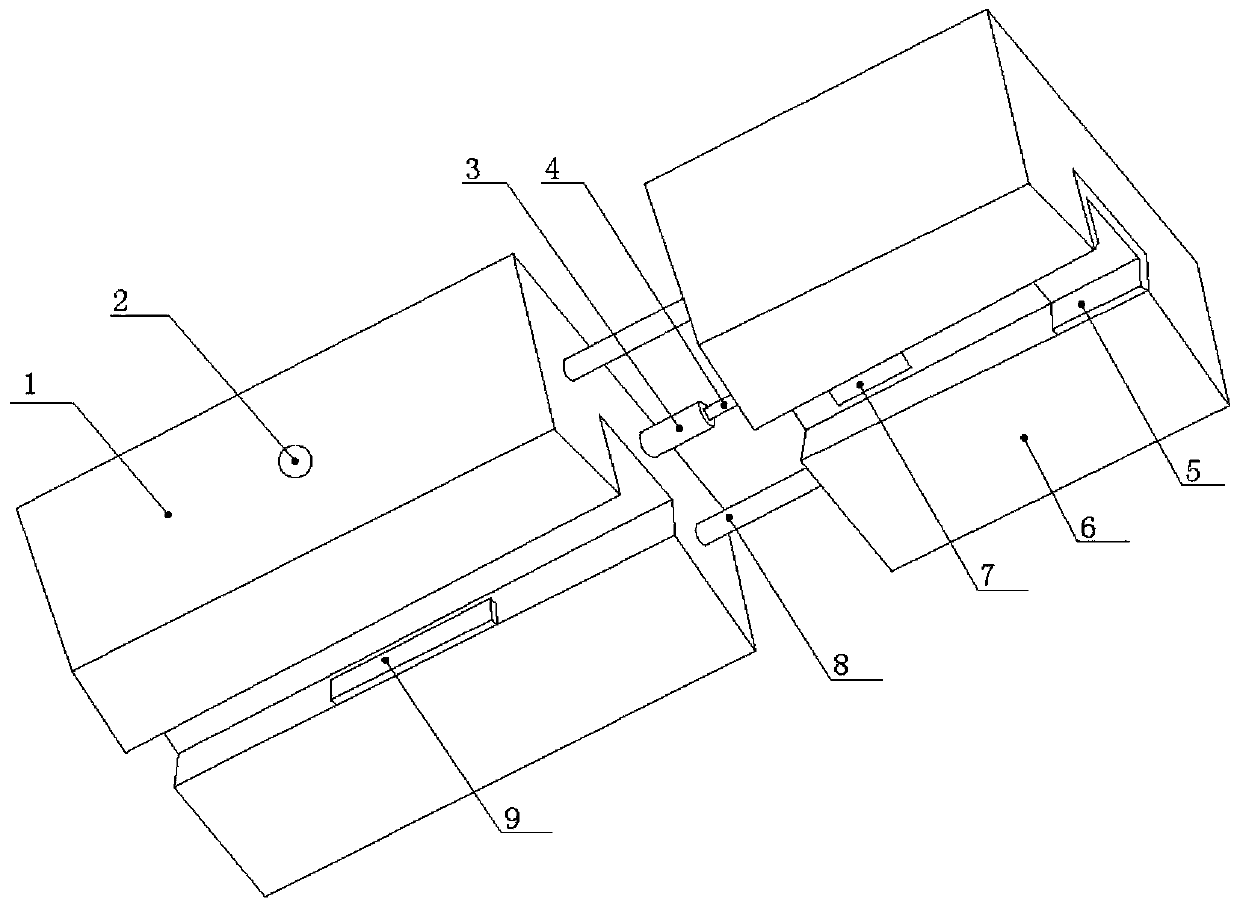

Automatic cold extruding device

InactiveCN106623652APlace stableProblems with large impact lossesMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention provides an automatic cold extruding device. The automatic cold extruding device comprises a first hydraulic machine, a second hydraulic machine, a material warehouse, a feeding mechanism, a transfer mechanism, a material taking mechanism, a positioning mechanism, a first power mechanism and a second power mechanism. The transfer mechanism comprises a first manipulator, a second manipulator, a sliding rail, a sliding block, a fixing groove, an air cylinder and a supporting mechanism. The first manipulator comprises a first mechanical arm and a first clamping mechanism. The second manipulator comprises a second mechanical arm and a second clamping mechanism. The first mechanical arm is arranged at one end of the sliding block, and the second mechanical arm is arranged at the other end of the sliding block. The positioning mechanism comprises a bracket and a transfer platform. The automatic cold extruding device has the beneficial effects that a workpiece obtained through primary punching is put into a sleeve through the first manipulator, the workpiece in the sleeve is taken out through the second manipulator to be subjected to secondary punching, and the problems that the subsequent secondary punching efficiency is affected and accordingly the workpiece loss is large due to the fact that the workpiece is prone to falling when transferred through a traditional transfer mechanism are solved.

Owner:哈尔滨工大工业机器人有限公司

Machine tool part corner angle polishing operation device and polishing method

InactiveCN112428071AEasy to moveSliding effectEdge grinding machinesPolishing machinesPolishingEngineering

Owner:安徽宇艳智能机械科技有限公司

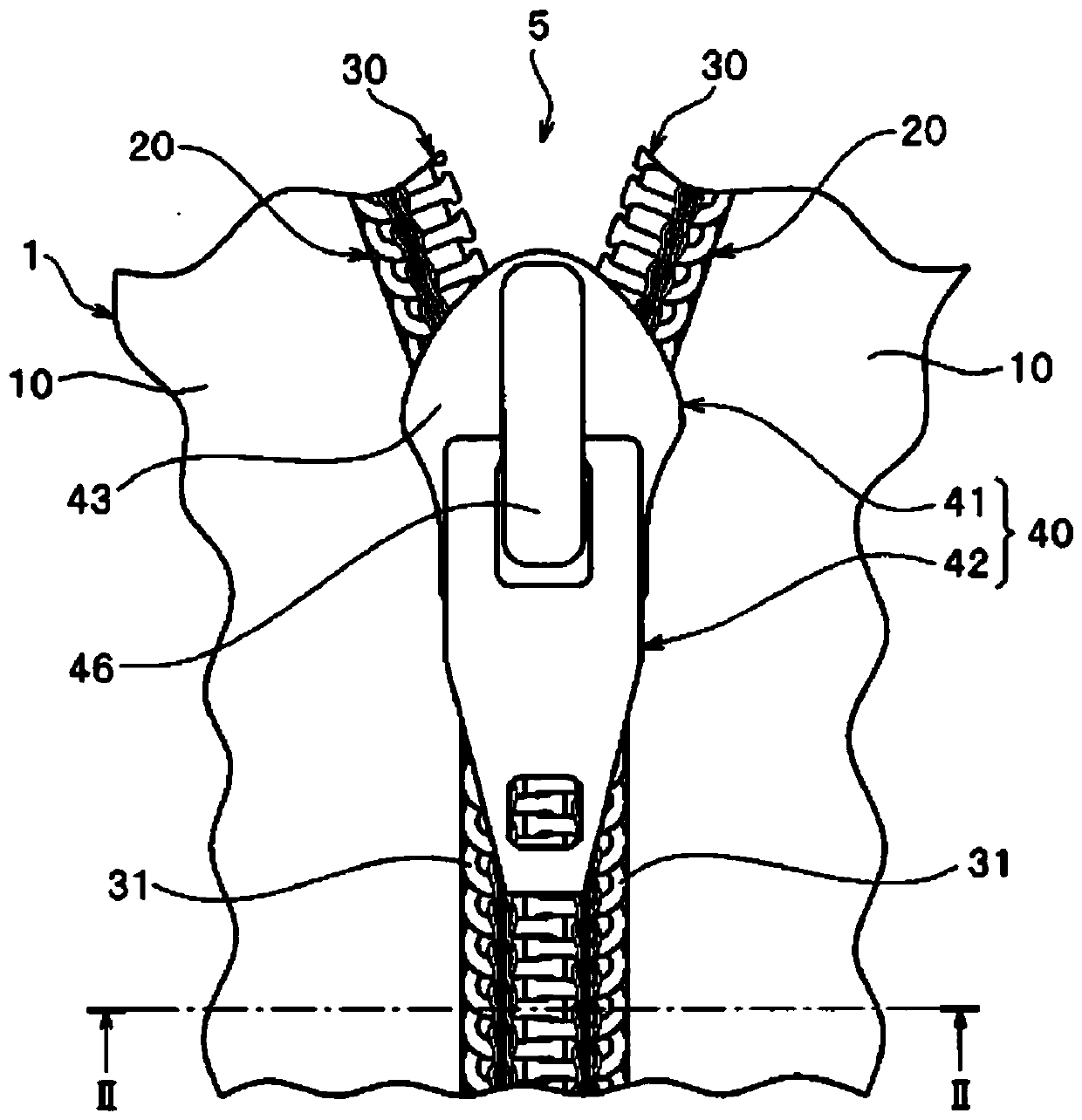

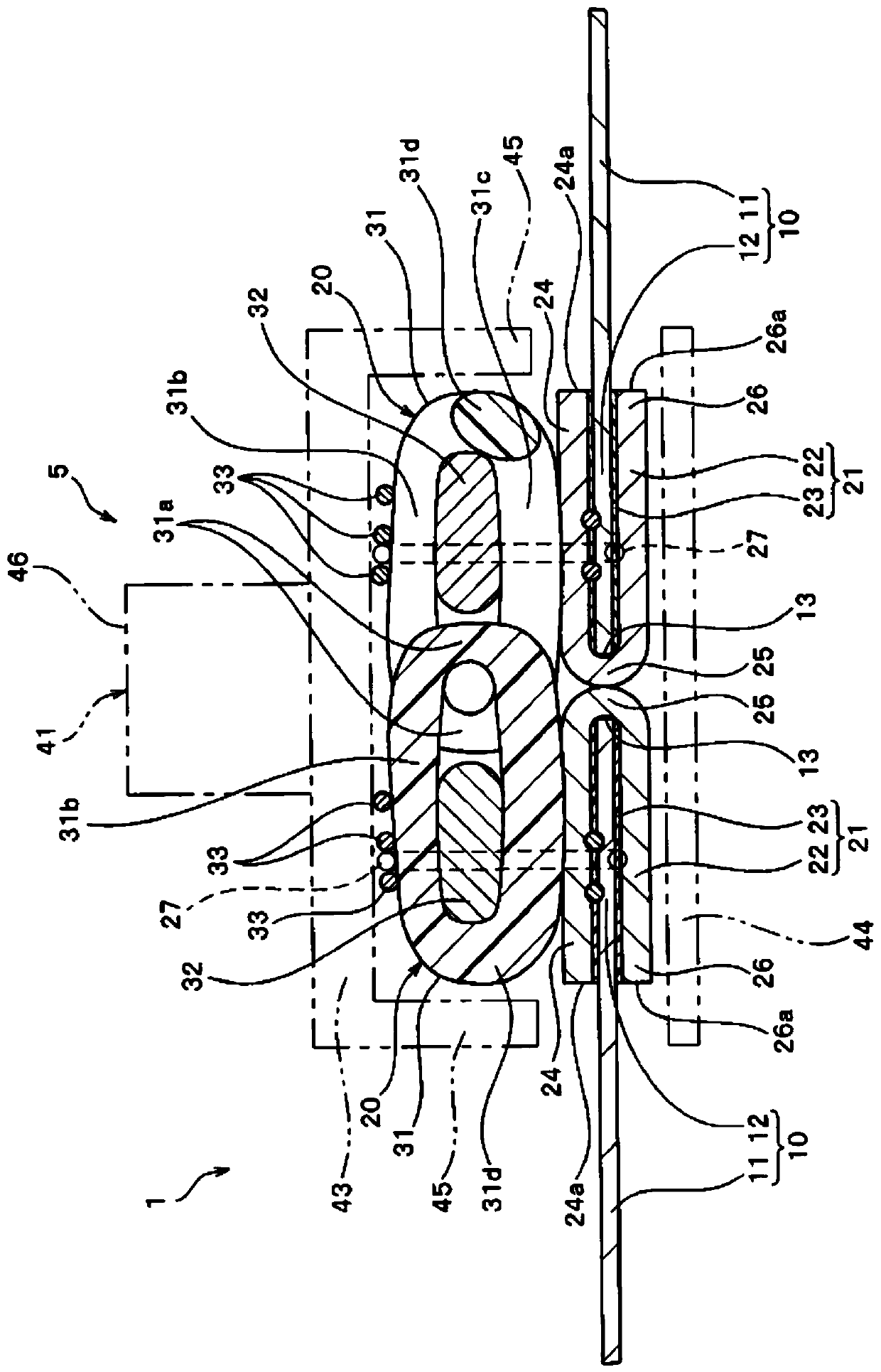

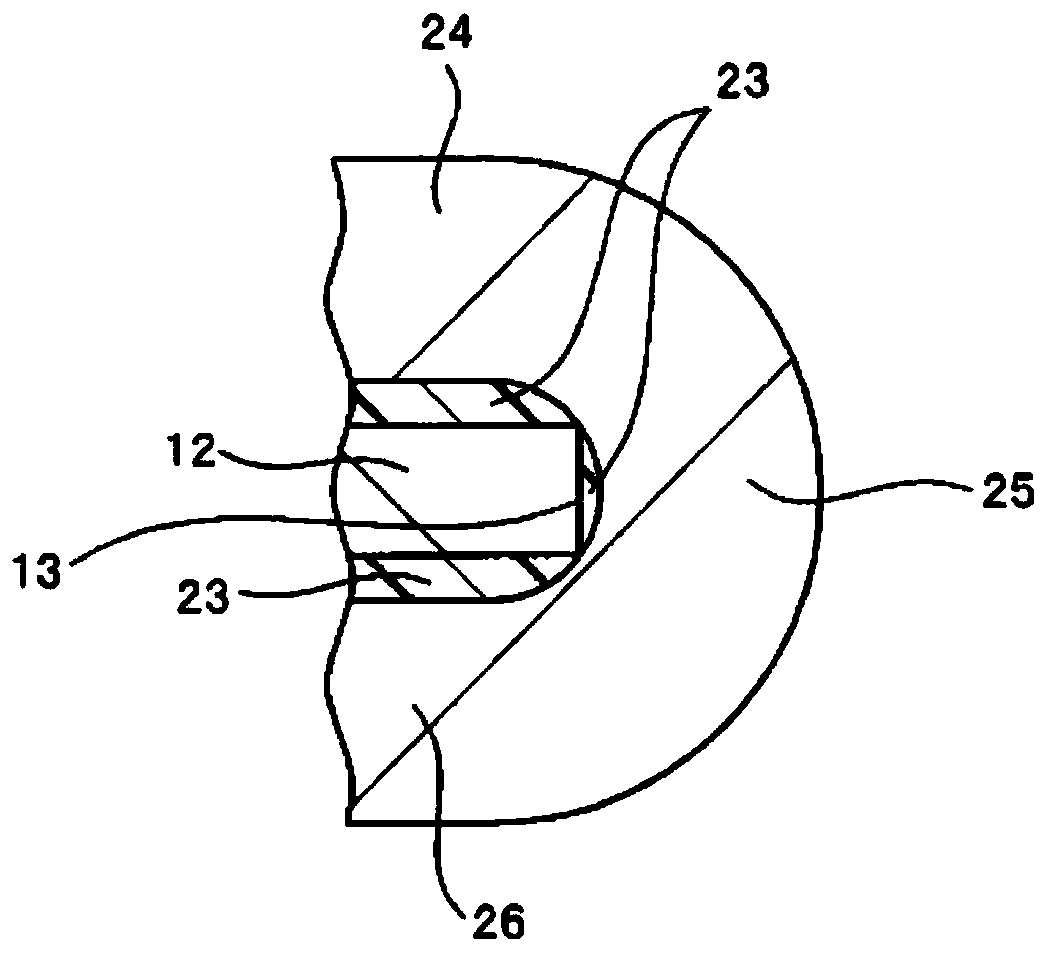

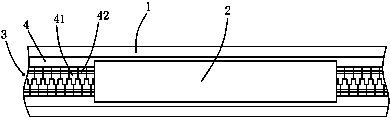

Product with slide fastener and method for manufacturing product with slide fastener

This product with a slide fastener (1, 1a, 1b) includes a pair of fastener stringers (20, 60) and a fastener receiving member (10) which has a pair of stringer-attaching parts (12). The fastener stringers (20, 60) are sewn to the fastener receiving member (10) with a stringer sewing thread (27). Each tape member (21, 51, 61) of the fastener stringers (20, 60) includes: a first tape piece (24, 54,64) to which a fastener element (31, 71) is attached; a tape bending part (25, 55, 65) which extends from the first tape piece (24, 54, 64) and is folded back in a U-shape; and a second tape piece (26, 56, 66) which is fixed to a second surface of the stringer attaching part (12). The second tape piece (26, 56, 66) covers the stringer sewing thread (27) exposed on the second surface of the stringer attaching part (12). Thus, side edges (13) of the fastener receiving member (10) are protected by the tape members (21, 51, 61) and deterioration of the slidability of a slider (40) caused by fraying is prevented.

Owner:YKK CORP

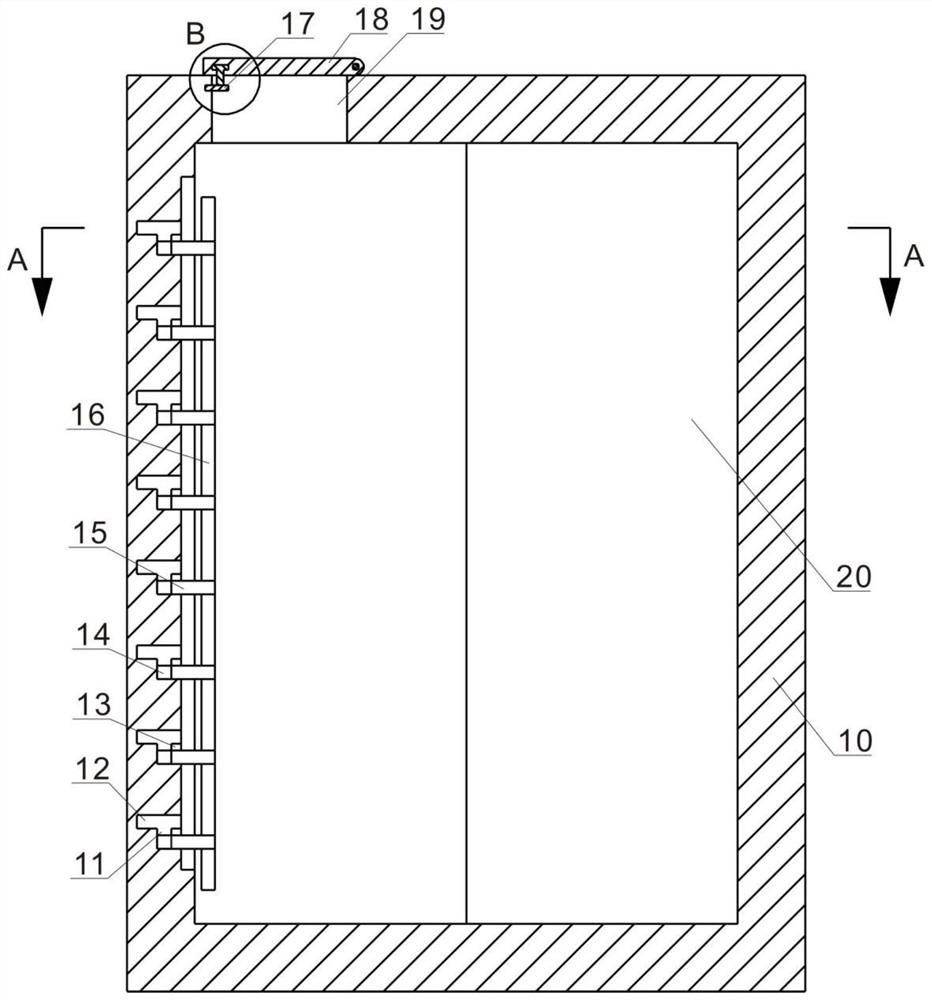

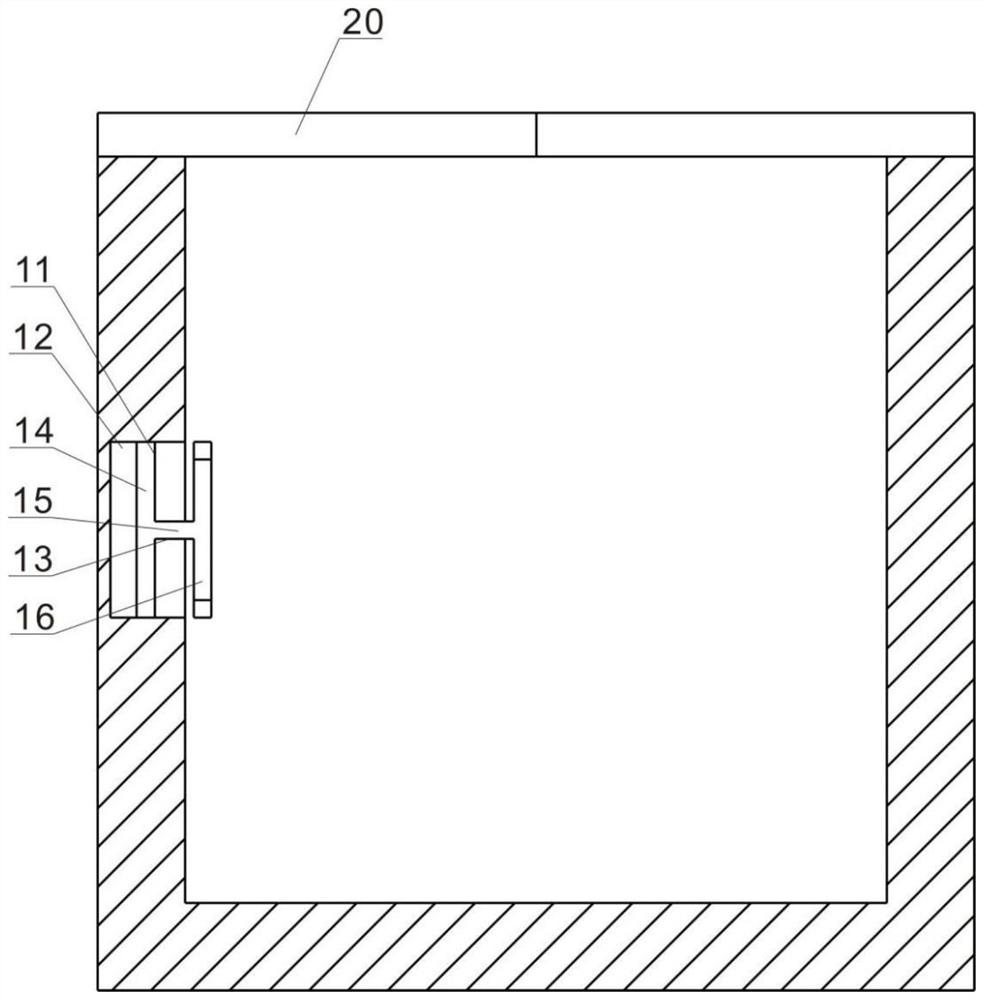

File management library based on real estate registration management

The invention relates to the field of file management, in particular to a file management library based on real estate registration management, which comprises a box body, wherein the side part of thebox body is provided with a box door, the inner part of the box body is provided with space for placing files, a slope is arranged on the top of the box body, a placing plate is movably connected with the slope, a placing groove for placing the file is arranged on the placing plate; a clamp for clamping the files is arranged in the placing groove; and the placing plate is connected with a drivingmechanism for driving the placing plate to slide. According to the scheme, the storage of files at the top of the management library is realized.

Owner:重庆光大网络技术有限公司

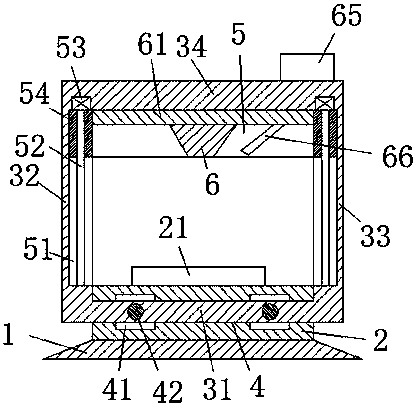

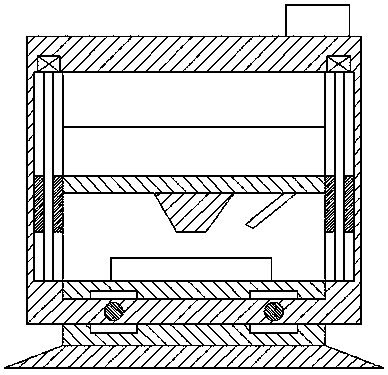

Heat insulation coating filling facility

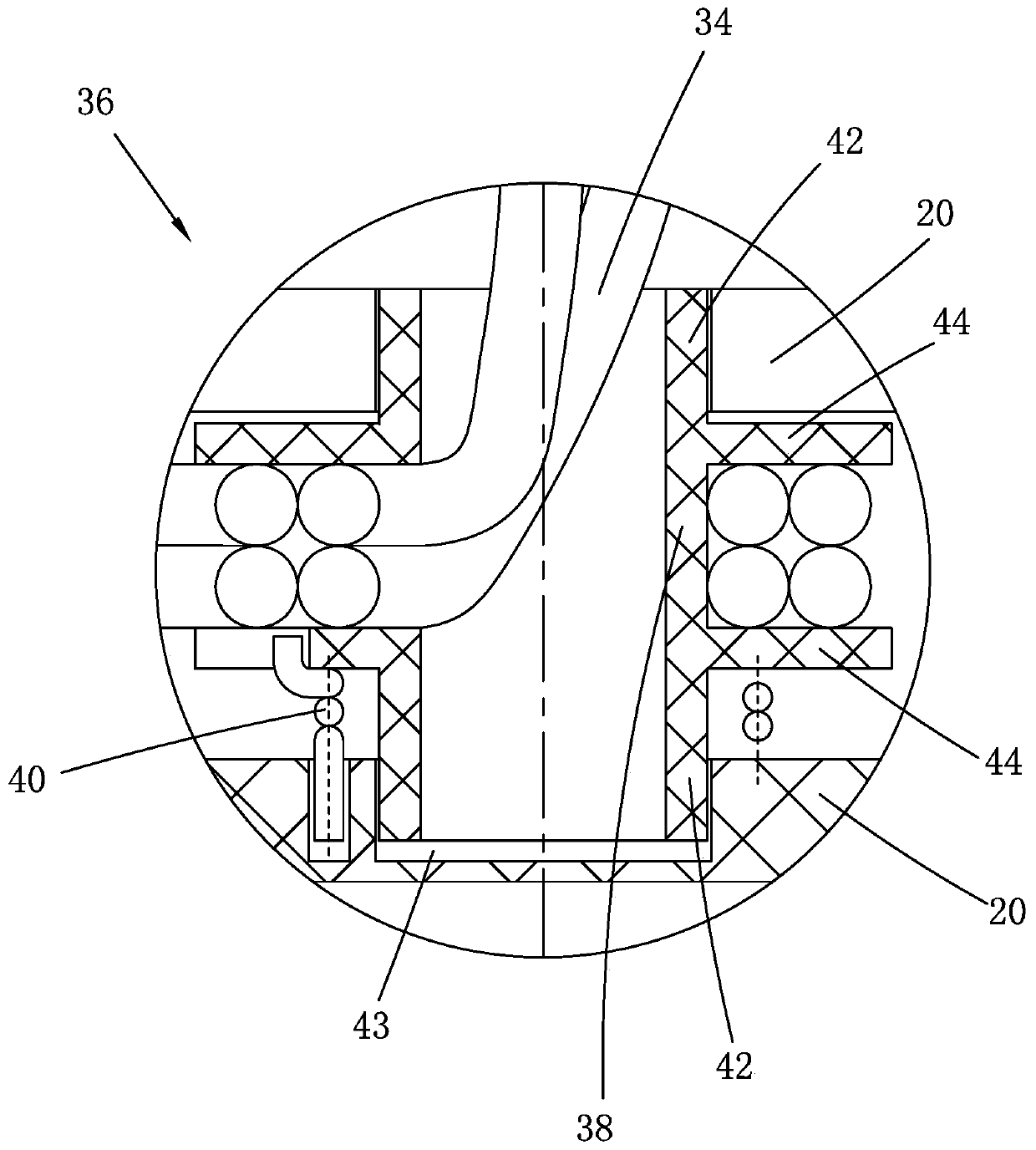

PendingCN108715433ASolve pollutionShort path of motionBarrels/casks fillingFilling device cleaningThermal insulationEngineering

The invention relates to the technical field of coating filling equipment, and discloses a heat insulation coating filling facility. The heat insulation coating filling facility comprises a machine platform. A filling position is arranged on the machine platform, a coating box is arranged above the filling position and connected with a filling pipe, and a filling valve is arranged on the filling pipe in a rotating mode. A protective mechanism is arranged on the machine platform, and comprises a rotating shaft, wherein the rotating shaft is arranged in a rotating mode. The rotating shaft is connected with a reciprocating driving mechanism, a driving gear is fixedly connected to the rotating shaft, and meshes with a driven gear, and the driven gear is fixedly connected with a lead screw which vertically penetrates through the machine platform. The lead screw and the machine platform are connected in a rotating mode, and a matched sliding sleeve is arranged on the lead screw in a sleevingmode. A stretching rod is arranged between the sliding sleeve and the machine platform, and the two ends of the stretching rod are fixedly installed on the machine platform and the sliding sleeve correspondingly. Baffles are fixedly connected to the sliding sleeve, located on the side of the filling position and used for sheltering a splashing coating. By means of the heat insulation coating filling facility, the problem that due to the fact that the coating is prone to splashing, the processing environment and filling barrels are contaminated can be solved.

Owner:重庆阿罗科技有限公司

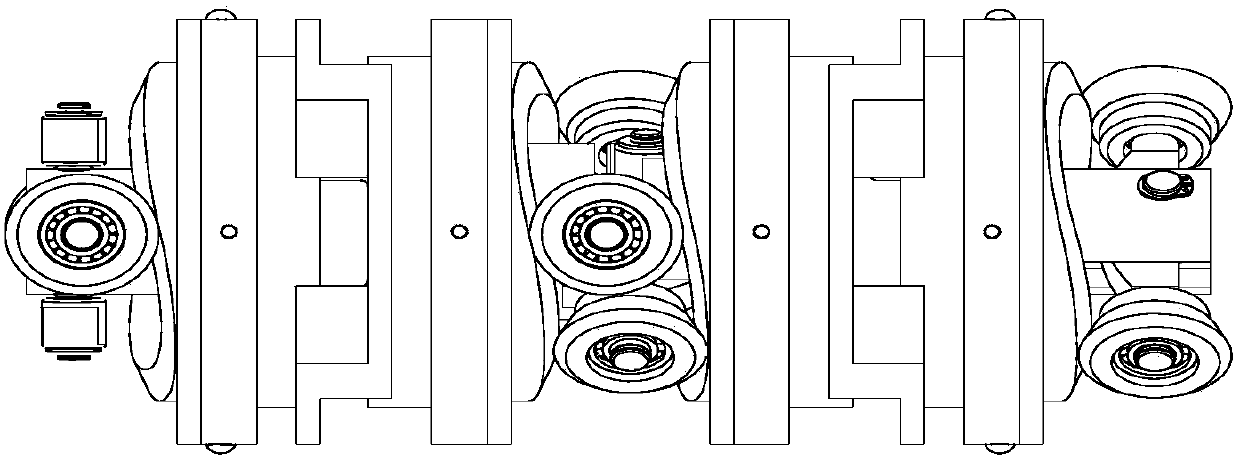

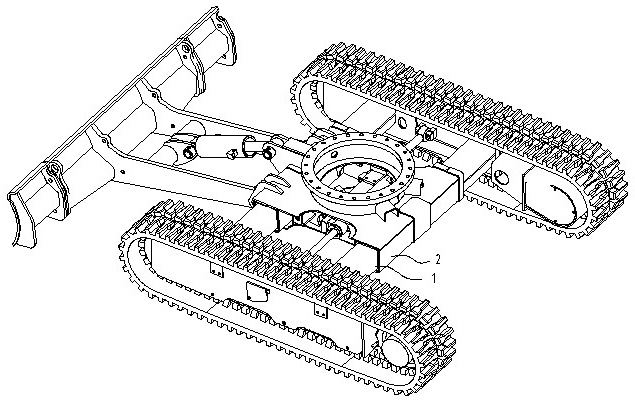

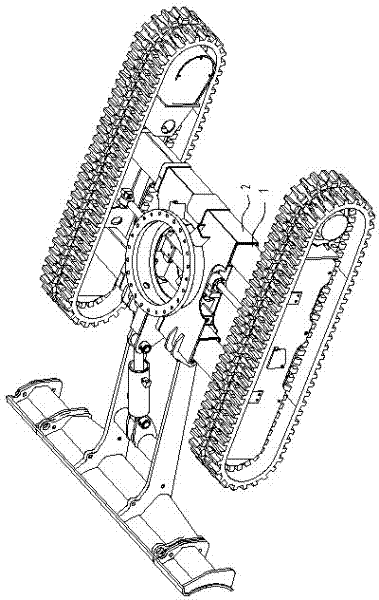

Crawler-type chassis telescopic mechanism

InactiveCN102019971APrevent left and right movementPrevent deviationEndless track vehiclesRolling chassis

The invention discloses a crawler-type chassis telescopic mechanism, comprising a telescopic arm and a telescopic guide rail sheathed on the telescopic arm, wherein a sliding gap is arranged between the telescopic arm and the telescopic guide rail, and the telescopic arm slides along the extending direction of the telescopic guide rail in a reciprocating way. The telescopic mechanism is characterized in thatthe left and right upper sides of the telescopic arm and the top of the telescopic guide rail are inclined planes, the included angles between the left and right upper sides and the top surface are 10-60 degrees, an upper limit block is respectively arranged on the left and right upper sides of the telescopic guide rail between the telescopic arm and the telescopic guide rail, and a sliding gap is arranged between each upper limit block and the telescopic arm. In the invention, an inclined telescopic arm and the upper side of the telescopic guide rail are arranged, and a limit block is arranged at the inner side of the inclined plane of the telescopic guide rail, so that the limit block is appressed with the inclined plane of the telescopic arm under the action of gravity, limit of the telescopic arm in the left and right directions is realized, the telescopic arm is prevented form moving left and right, the phenomenon that the chassis pulls to one side is avoided, and rgw operation stability is improved.

Owner:SANY HEAVY MACHINERY

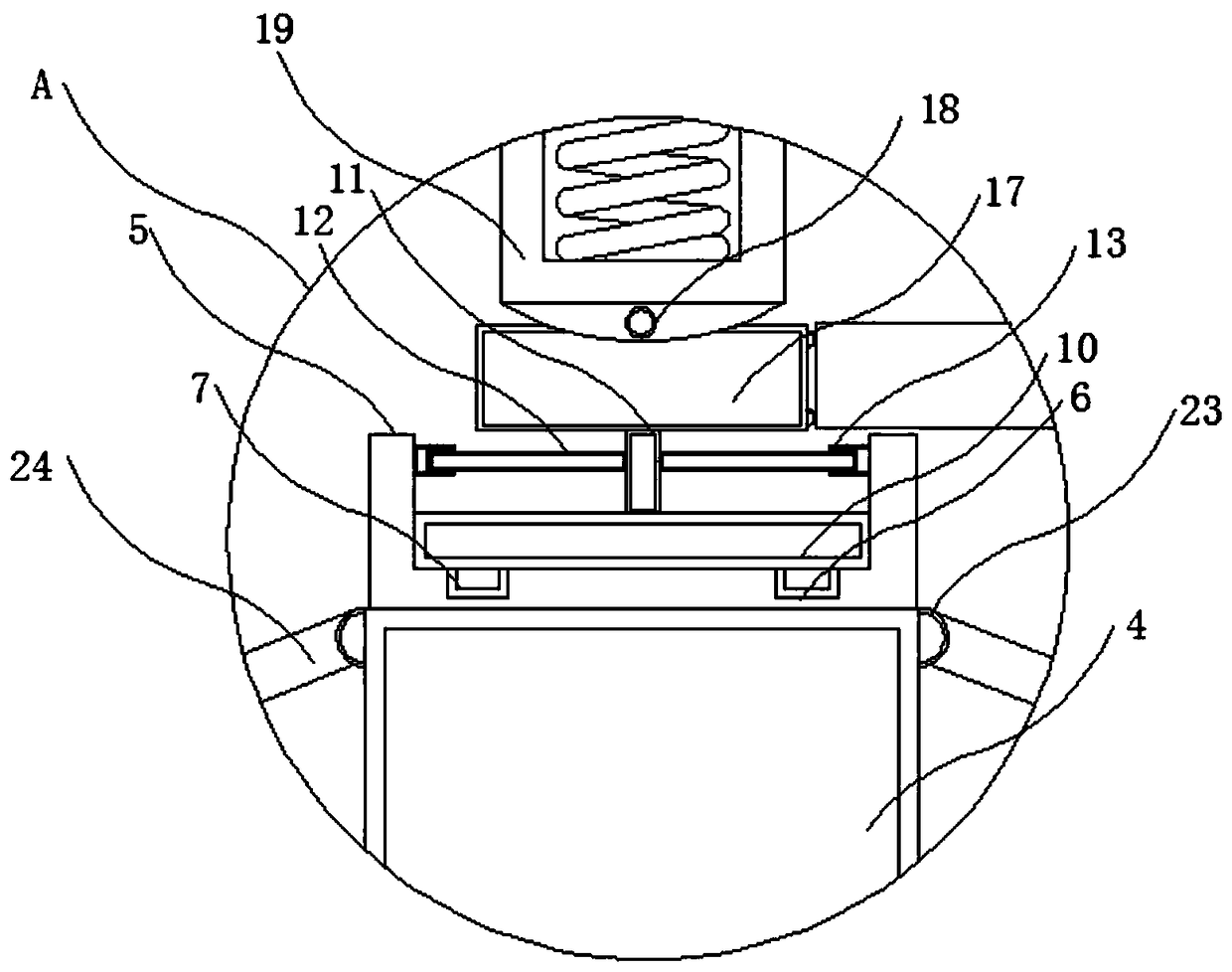

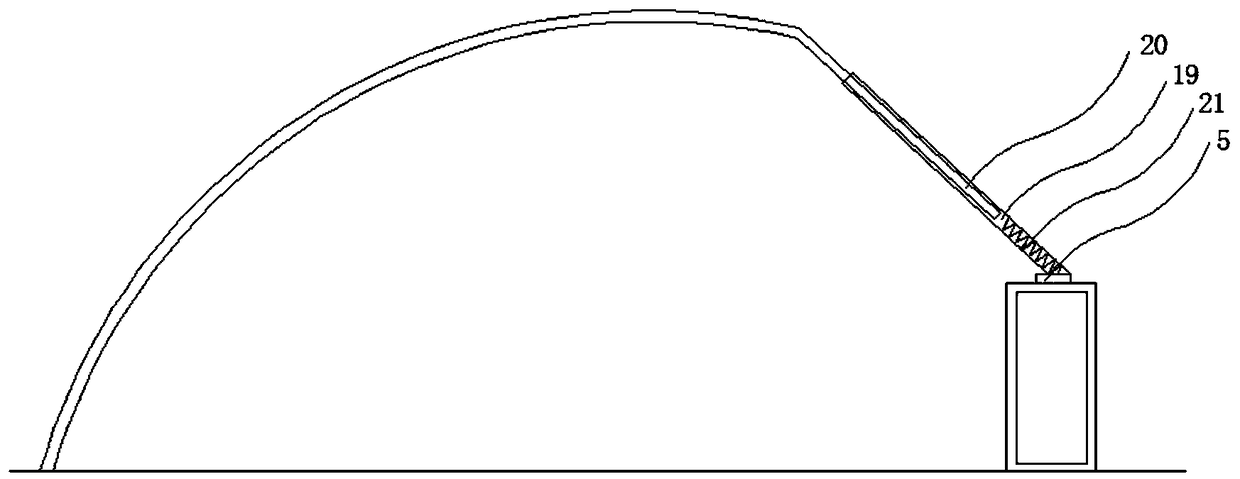

Supporting structure for back slope of solar greenhouse

PendingCN109315192ASliding effectImprove stabilityClimate change adaptationGreenhouse cultivationSolar greenhouseEngineering

The invention discloses a supporting structure for a back slope of a solar greenhouse, and relates to the technical field of solar greenhouses. The supporting structure particularly comprises a mounting plate and a connecting outer rod, wherein the outer wall of the mounting plate is fixedly provided with a baffle, the upper end of a sliding block is fixedly provided with a movable plate, the middle of the upper end of the movable plate is fixedly provided with a vertical rod, the upper portion of the inner wall of a working frame is fixedly provided with a second positioning strip, the upperend of the working frame is provided with a fixing strip, the upper end of the vertical rod is fixedly provided with an adjusting plate, the tail end of the connecting outer rod is fixed to the outerwall of a first rotating shaft, the outer wall of the adjusting plate is provided with a strip folding mechanism, and a bolting device is arranged between the inner walls of the baffle and supportingplate. The supporting structure for the back slope of the solar greenhouse has the advantages that under the action of external thrust, the movable plate slides in a sliding groove back and forth through the sliding block, so that a moving effect on the movable plate is achieved, and the supporting structure can be entirely moved according to the form of a slope, so that the entire stability of the supporting structure is better.

Owner:WEIFANG UNIV OF SCI & TECH

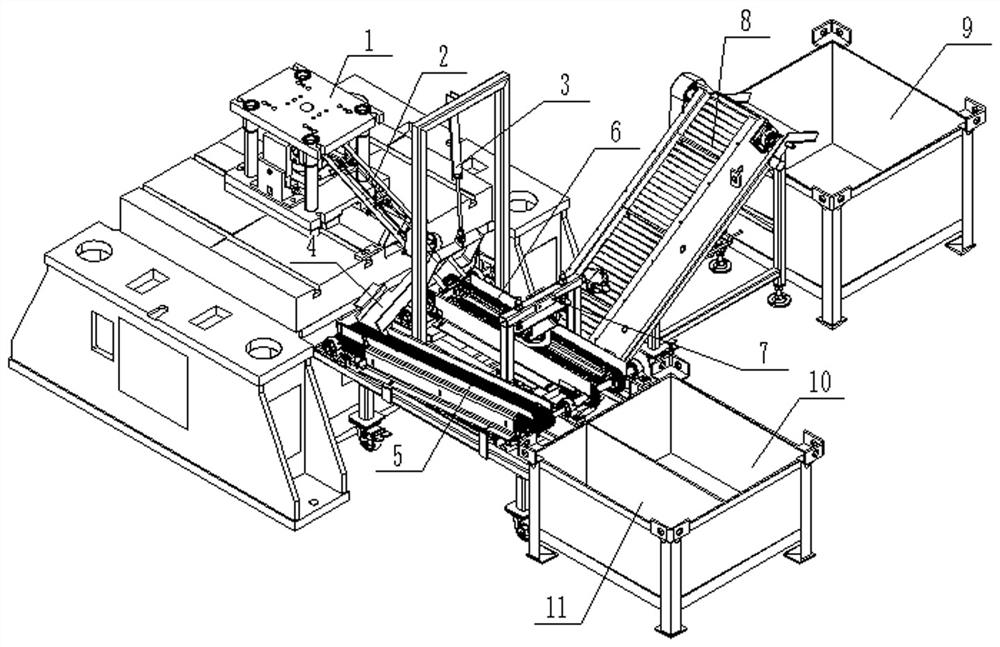

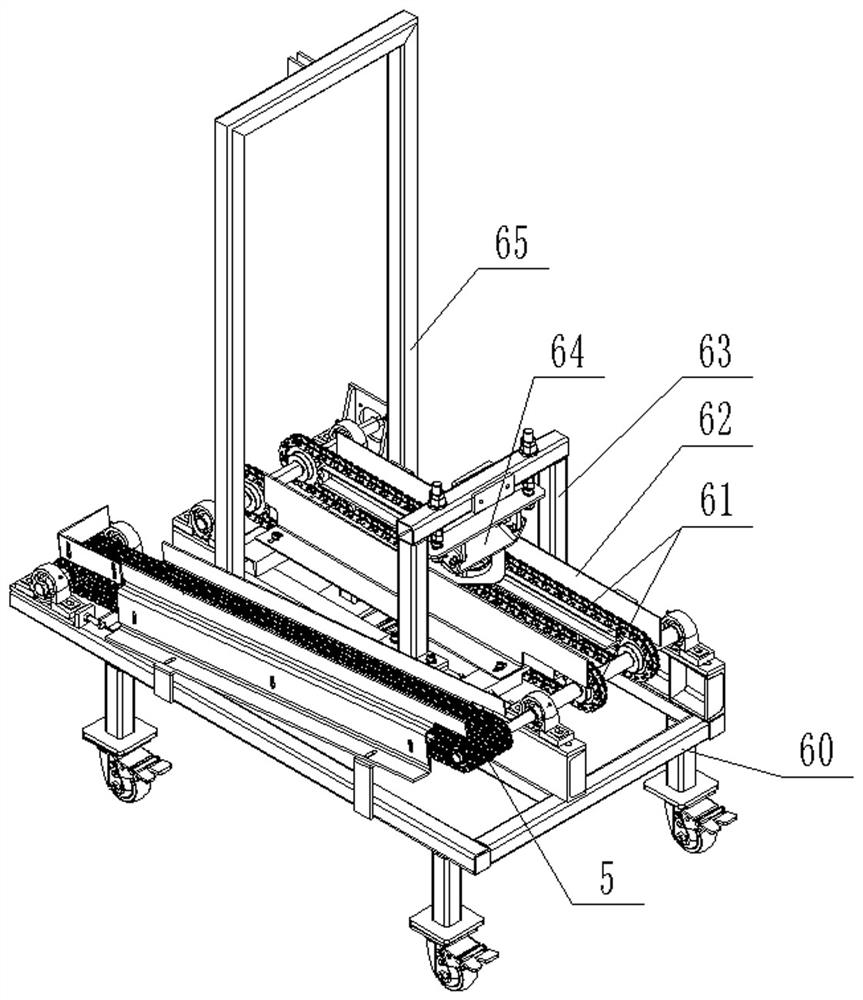

Automatic separating and discharging device for double-fork forgings

ActiveCN113426912AAvoid incomplete separationPlay a secondary separation effectMetal-working feeding devicesStripping-off devicesChain linkTransfer line

The invention discloses an automatic separating and discharging device for double-fork forgings, and belongs to the field of punching, separating and conveying. The device comprises a recess separating and conveying slide way, the recess separating and conveying slide way is inclined downwards, a stop lever is arranged below the tail end of the recess separating and conveying slide way, and when the double-fork forgings slide downwards, double forgings at the bottom are in contact with the stop lever to turn over the double-fork forgings; a flash separating and conveying line is arranged at the bottom of the tail end of the recess separating and conveying slide way, the recess separating and conveying line comprises two parallel flash conveying chains, a pressing device is arranged above the two flash conveying chains, the double forks of the double-fork forgings on the flash conveying chains can be pressed down by the pressing device, and a double-fork conveying line is arranged at the bottom of the middle of the two parallel flash conveying chains; and the device further comprises a recess conveying chain, the recess conveying chain is arranged on one side of the flash separating and conveying line, a wad collecting inclined sliding way is arranged at the bottom of the recess separating and conveying sliding way, the recess conveying chain is arranged at the tail end of the wad collecting inclined sliding way, and separation and collection of flashes, recesses and the double forks can be achieved through the structure.

Owner:山东豪迈精锻科技有限公司

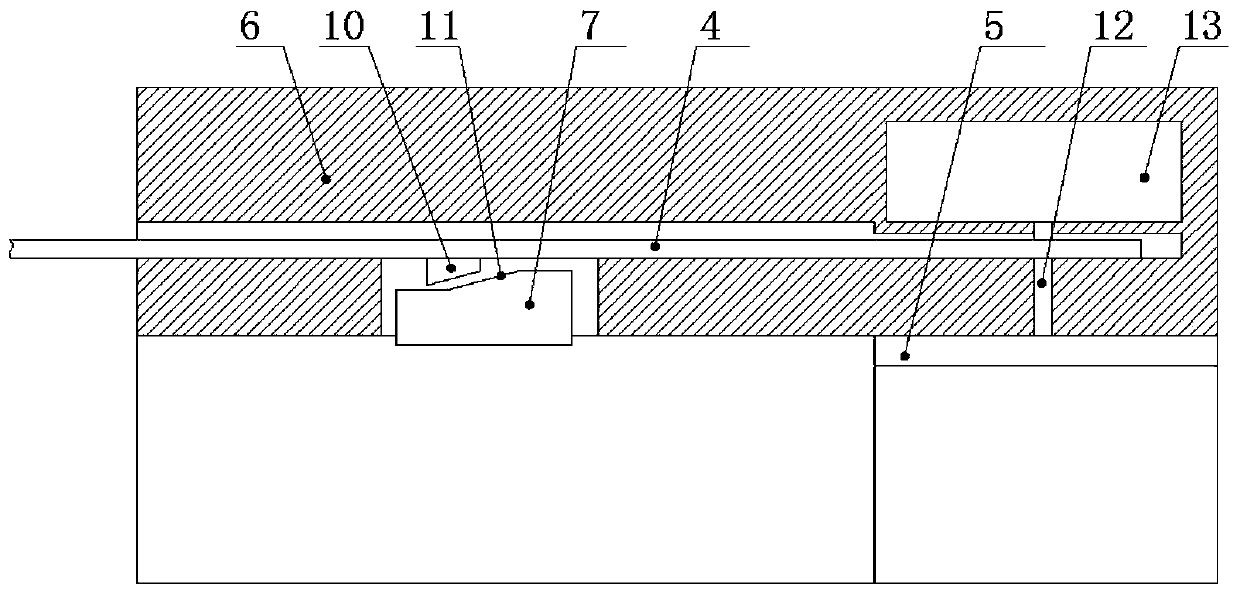

Positioning clamp device with automatic cleaning function

ActiveCN110181290ASimple structureEasy to operateLarge fixed membersMaintainance and safety accessoriesFriction lossForeign matter

The invention relates to the technical field of machine tools, in particular to a positioning clamp device with an automatic cleaning function. A clamping block arranged on the inner wall of a slidingblock in a sliding manner is included, wherein the sliding block is used for being connected with a guide rail. The clamping block is connected with a drive mechanism for driving the clamping block to slide. The front end, in the motion direction, of the sliding block is provided with a cleaning block which is in sliding connection with the guide rail. The inner wall of the cleaning block is provided with a wiping piece for wiping the guide rail. The positioning clamp device solves the problems that in the prior art, foreign matter on a guide rail is clamped between a sliding block and the guide rail, sliding block sliding is influenced, and consequently the sliding block and guide rail friction losses are large.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

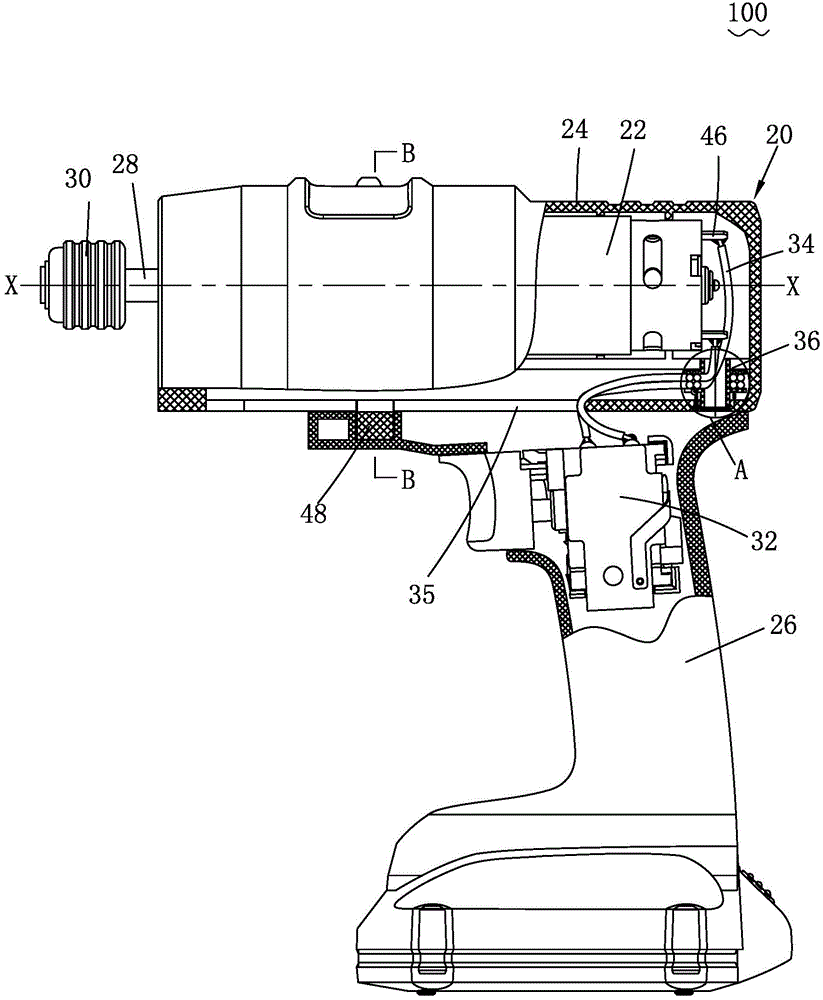

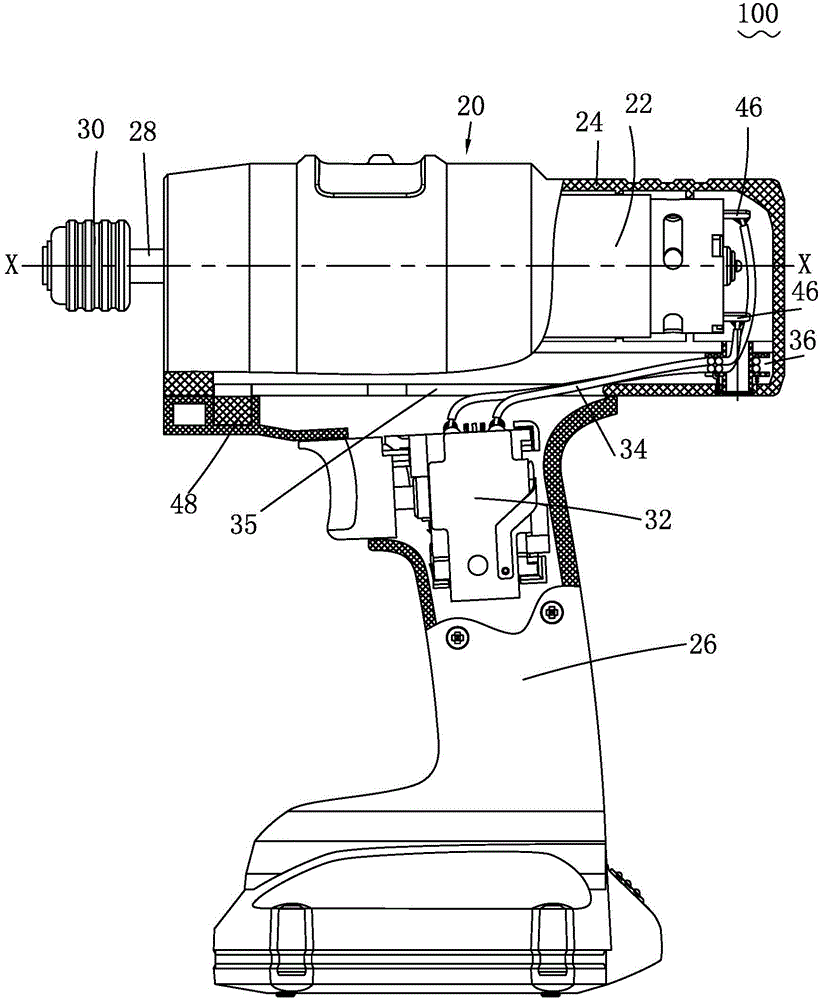

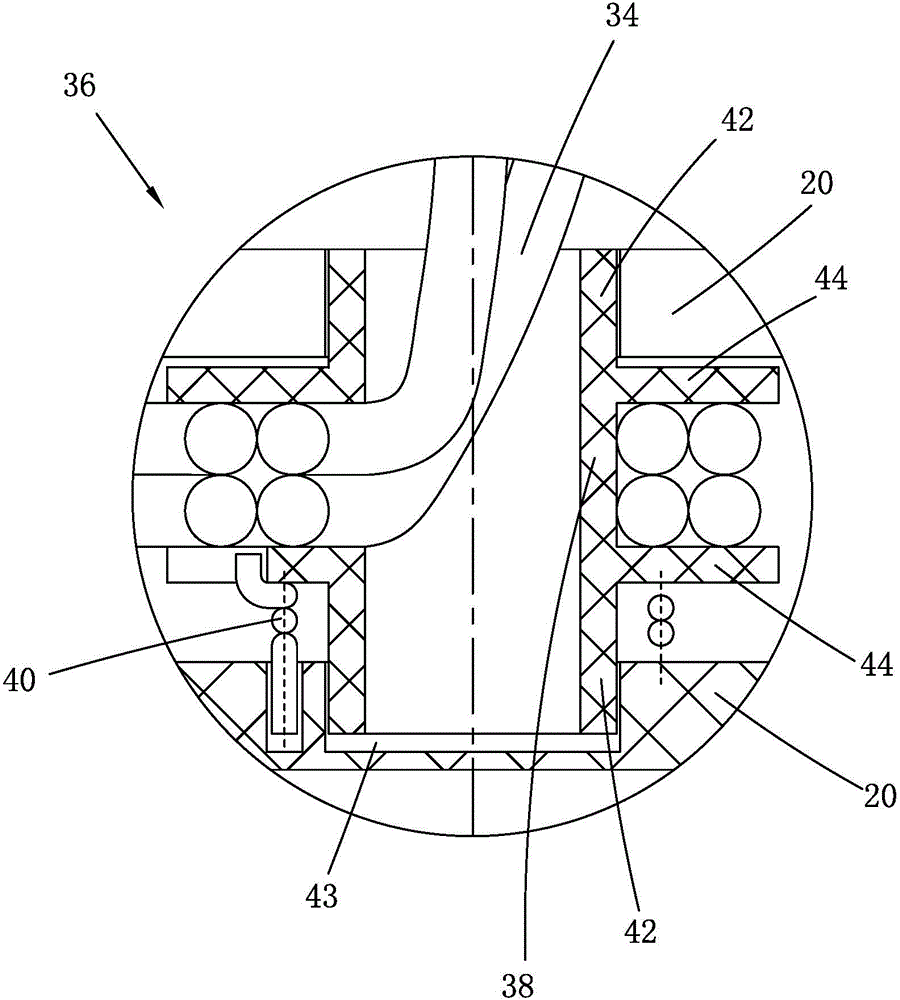

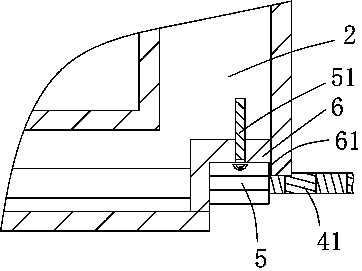

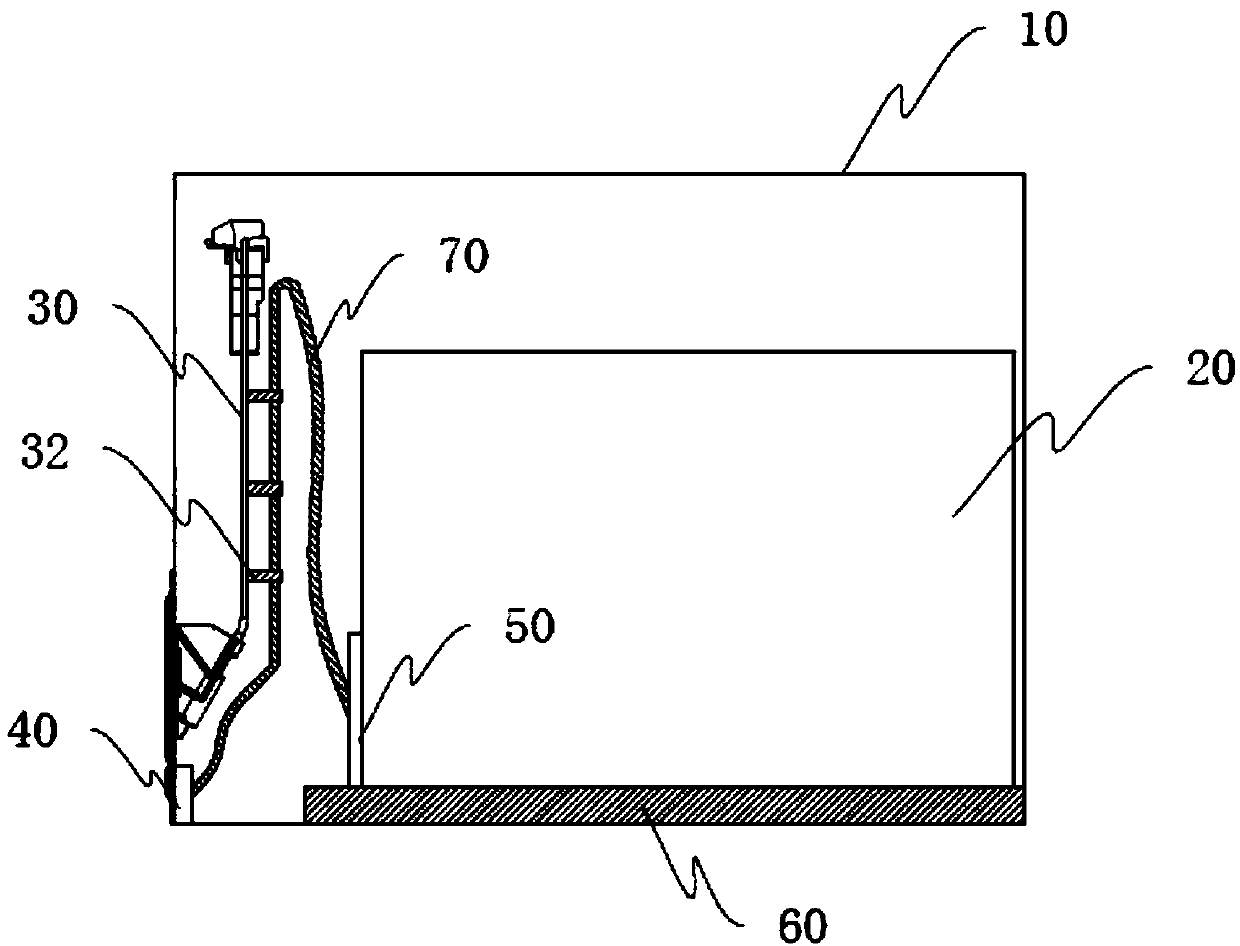

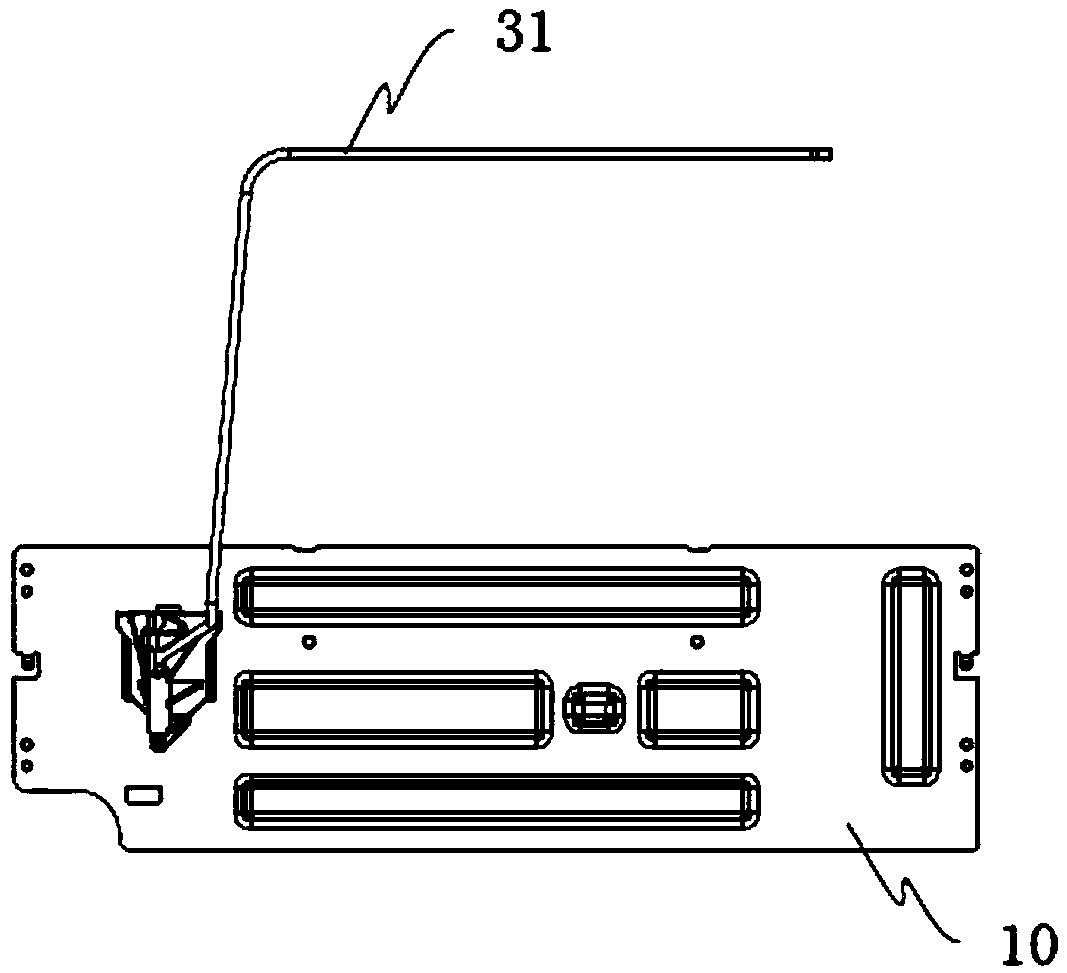

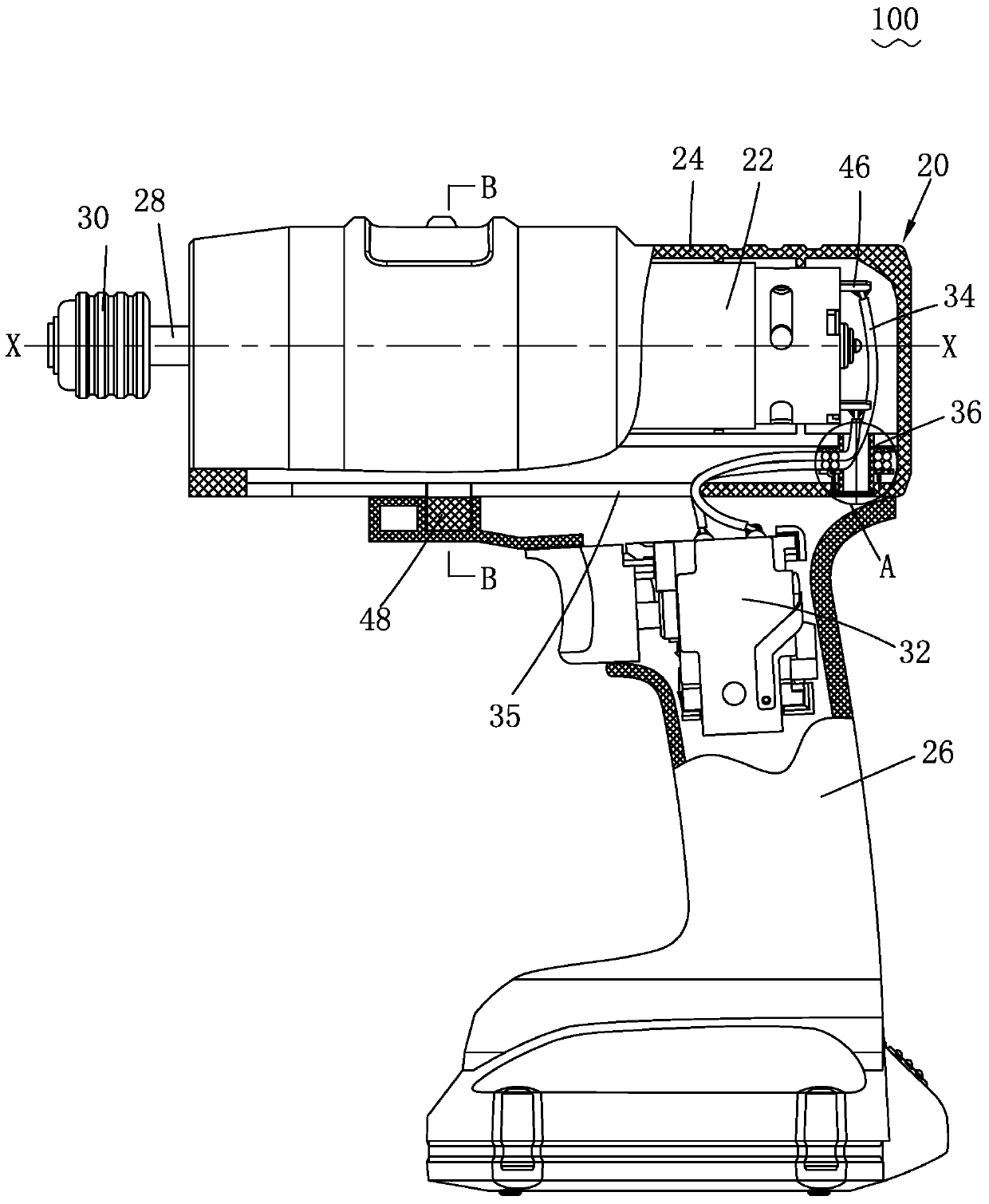

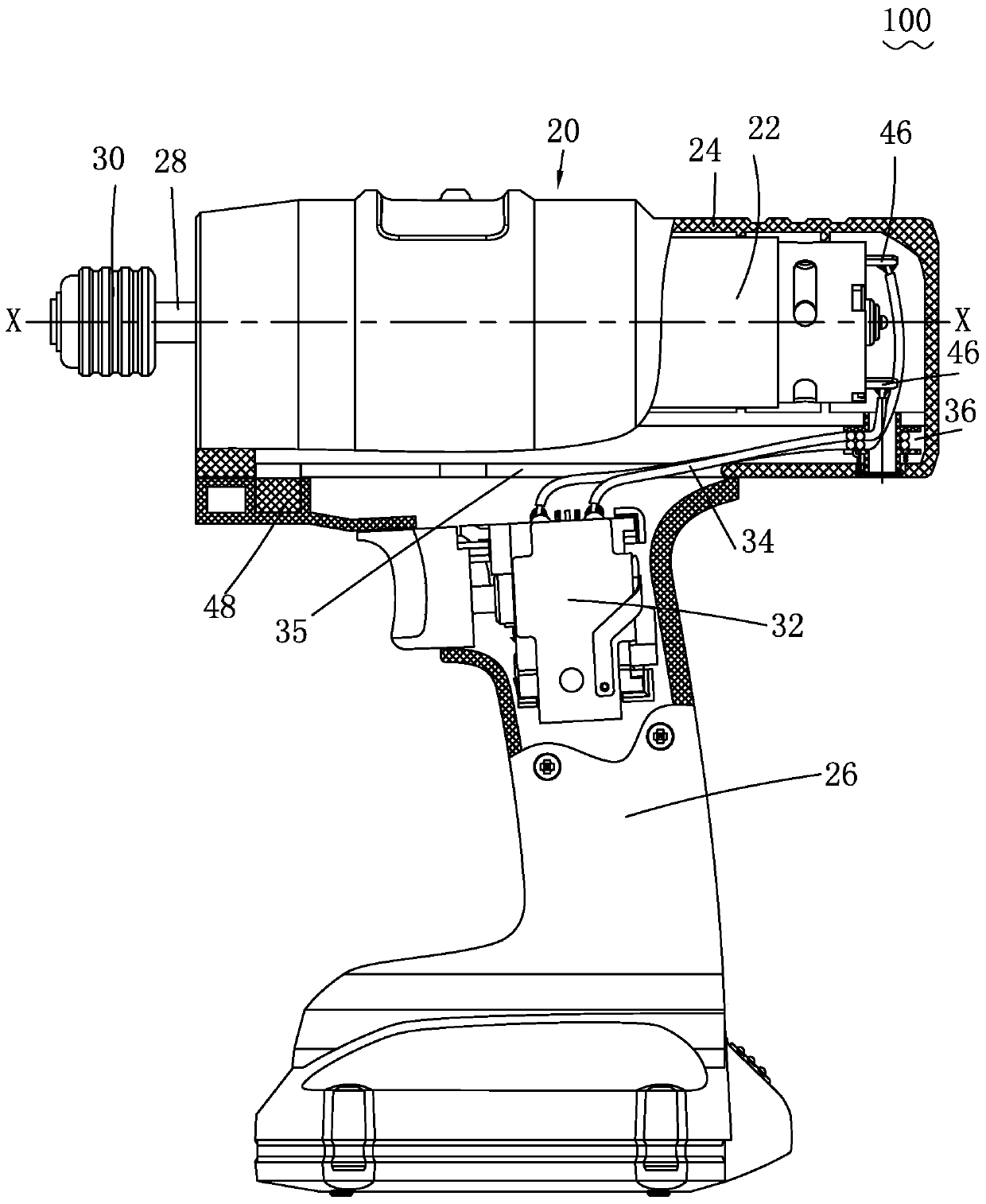

Power tool

ActiveCN104942770ASliding effectEffective and regularPortable power-driven toolsElectricityMotor drive

The invention provides a power tool. The power tool comprises a shell. The shell comprises a machine shell used for containing a motor and a handle which is connected with the machine shell. An output shaft of the motor drives an output rod to move through a transmission mechanism. The output shaft is provided with an axis. The handle and the machine shell are in sliding fit connection in the extending direction of the axis. The handle is provided with a control piece. The control piece and the motor are electrically connected through a wire. The shell is provided with a winding device. The winding device tensions the wire in the winding direction of the tensioned wire. The wire can be effectively arranged, and it is avoided that sliding of the handle relative to the machine shell is affected due to the disordered wire.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

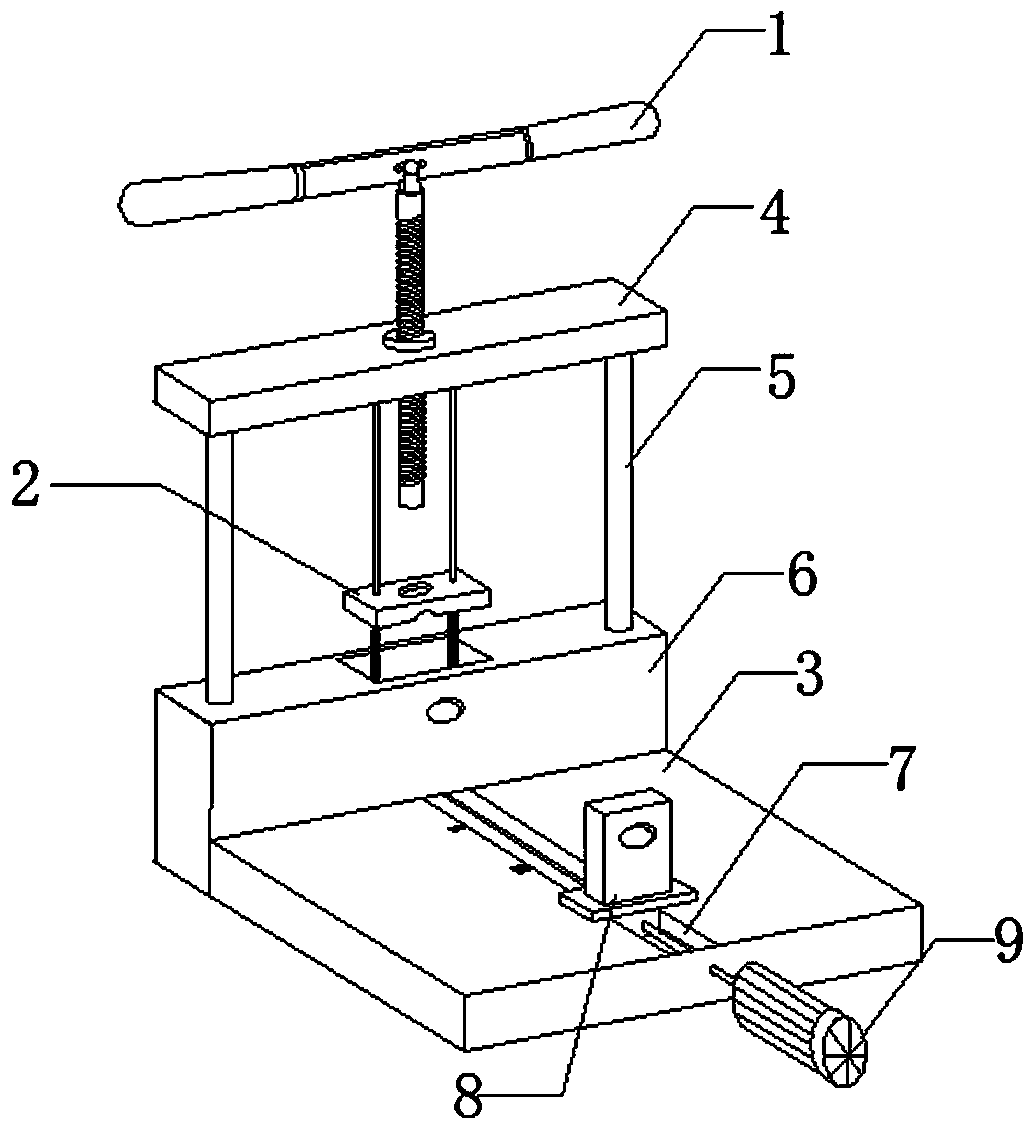

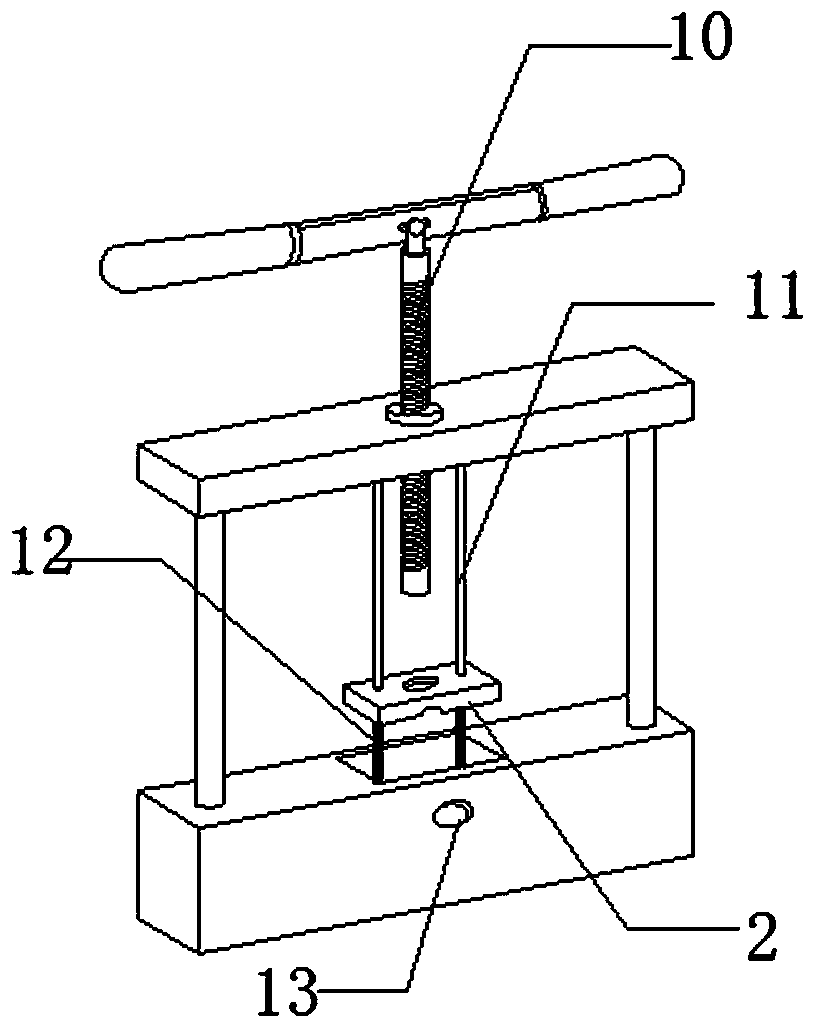

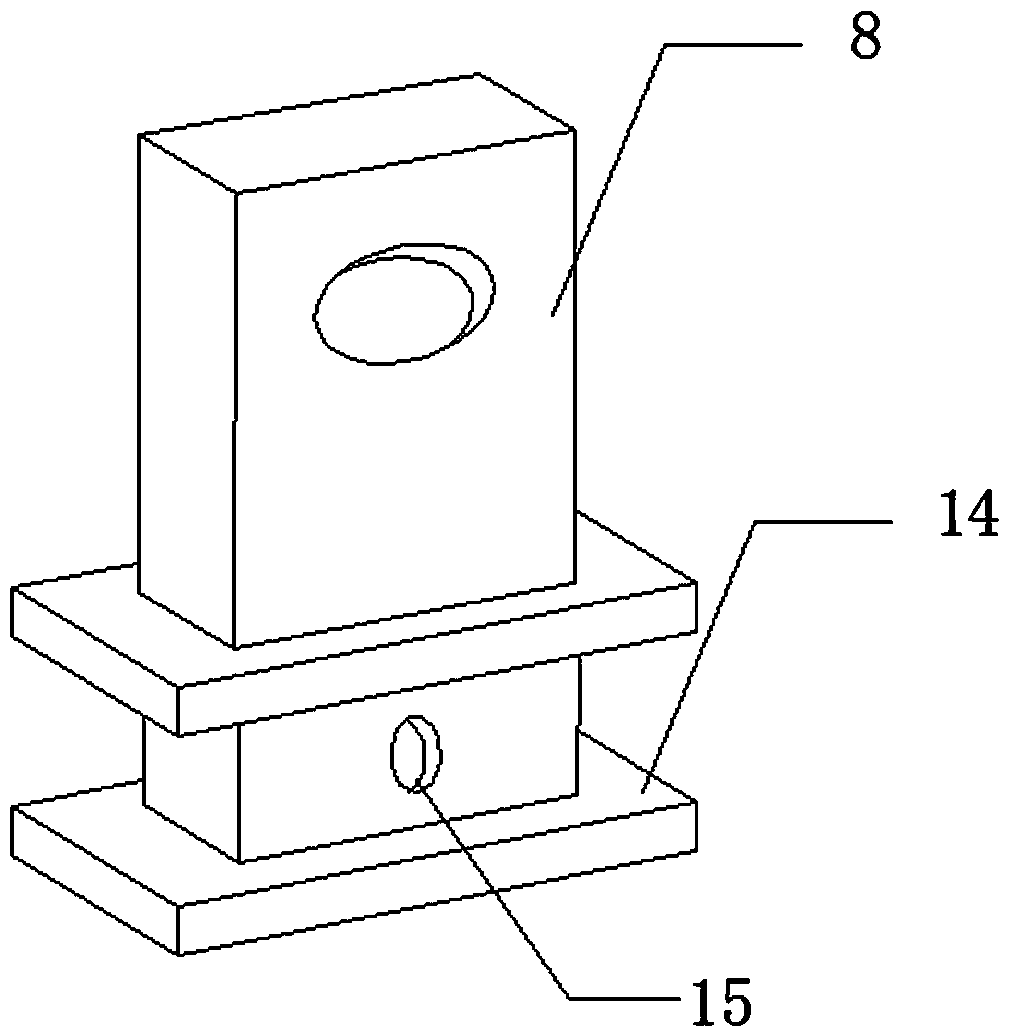

Positioning device for cutting steel pipes

InactiveCN109894884AEasy to fixFixed and accurateMeasurement/indication equipmentsPositioning apparatusMechanical engineering

The invention discloses a positioning device for cutting steel pipes. The positioning device comprises a handle, a clamping plate, a worktable, a support plate, a strut, a base, a sliding groove, a support plate, an air blower, a screw, an iron rod, a spring, a clamping hole, a clamping plate, an air inlet hole, a screw hole and a clamping groove. The positioning device is provided with the clamping plate, a user can push the clamping plate to move by screwing the handle, the steel pipes are clamped through the clamping groove in the clamping plate, fixation of the steel pipes is facilitated,and cutting is more convenient to achieve; the support plate is arranged and is clamped into the sliding groove, and therefore the support plate can slide on the sliding groove back and forth, the user can identify the lengths of the steel pipes according to the scale on the worktable, and the steel pipes are cut more accurately; and the air blower is arranged, and therefore the air blower can beused for blowing chippings generated in the cutting process out of the sliding groove, and the condition that the chippings are accumulated in the sliding groove and sliding of the support plate is influenced are prevented. The positioning device has the characteristics of being firm in fixation and accurate in positioning.

Owner:湖南古新合盈机电有限责任公司

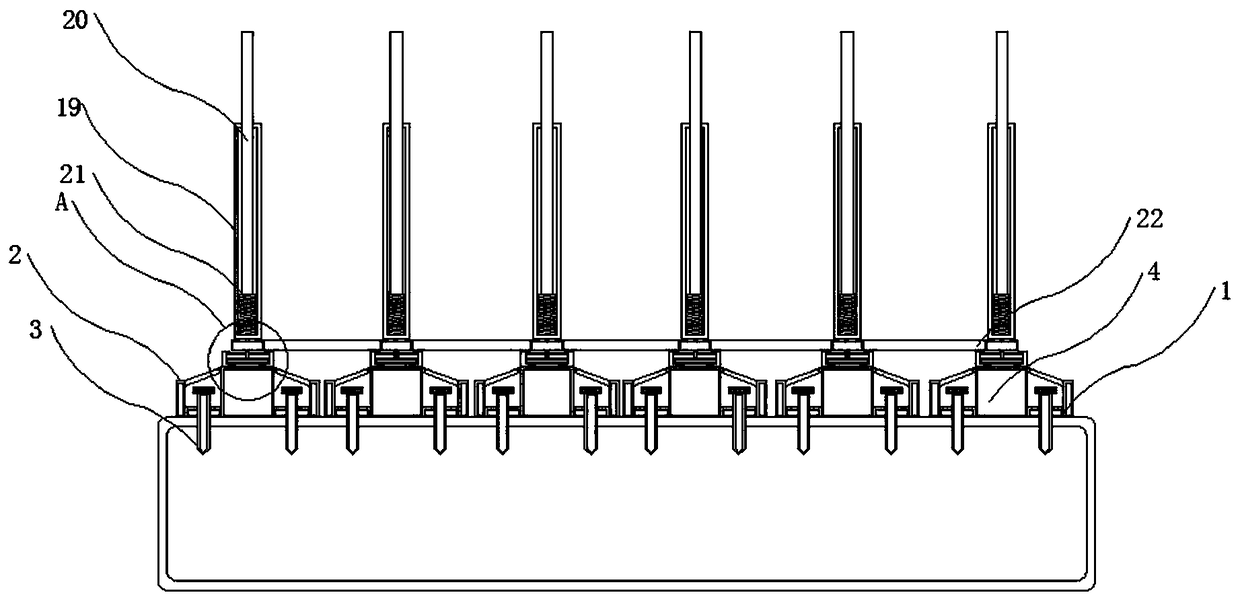

Soil sampler

PendingCN114199616ATake convenienceSliding effectWithdrawing sample devicesEarth material testingSoil scienceEngineering

The embodiment of the invention discloses a soil sampler, relates to the technical field of geotechnical engineering investigation equipment, and solves the problem of low water content measurement quality of the soil sampler. The soil sampler comprises a base, a soil sampling tube and a detection assembly, wherein the base is used for being connected with a drill rod; the soil sampling pipe is fixedly connected with the base; the detection assembly is located in the soil sampling tube, is slidably connected with the soil sampling tube through a sliding mechanism and comprises a water content detection part and a supporting rod, the first end of the supporting rod slidably extends out of the base, and the second end of the supporting rod is fixedly connected with the water content detection part and is close to the end, away from the base, of the soil sampling tube. The soil sampler is used for sampling a soil sample and measuring the water content of a soil body.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

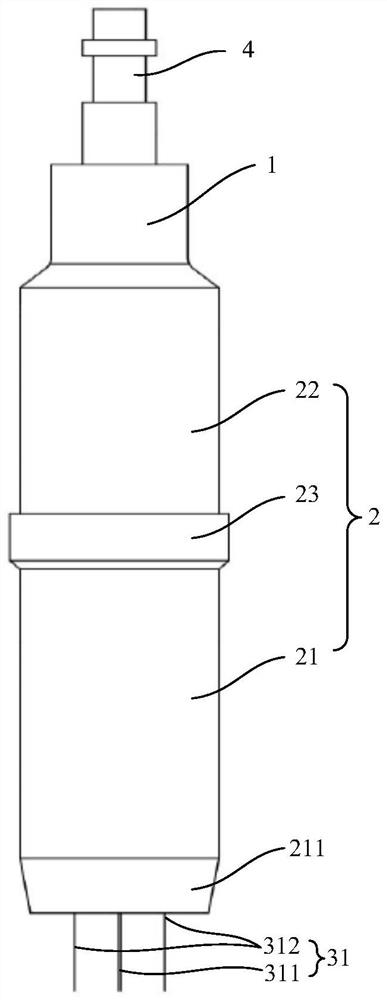

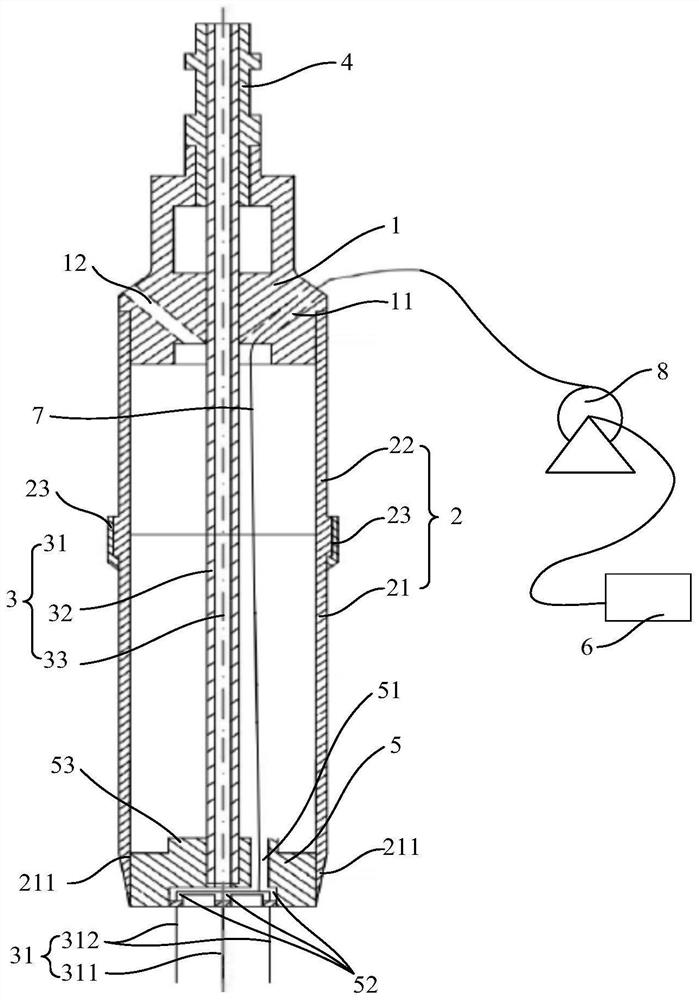

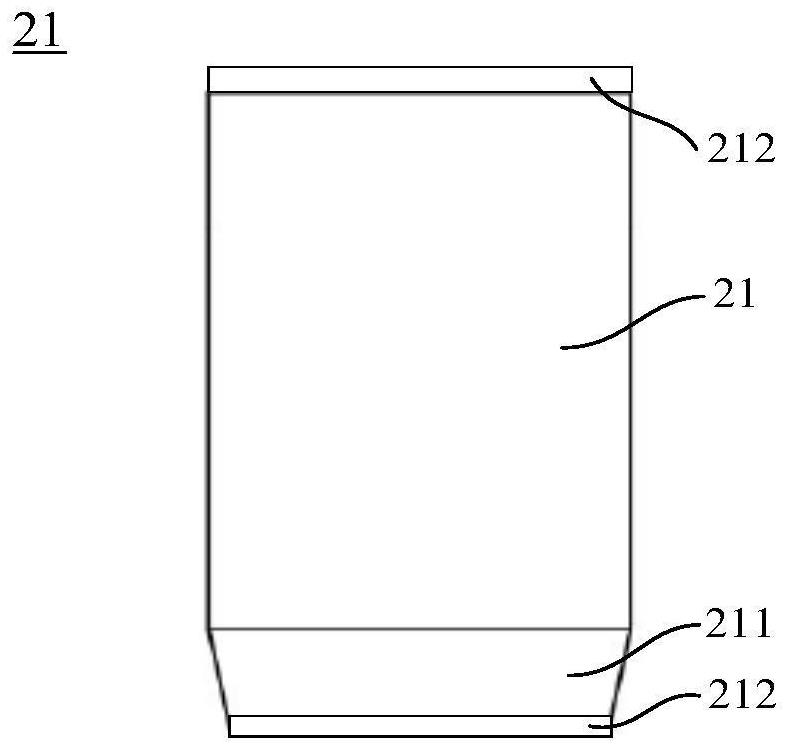

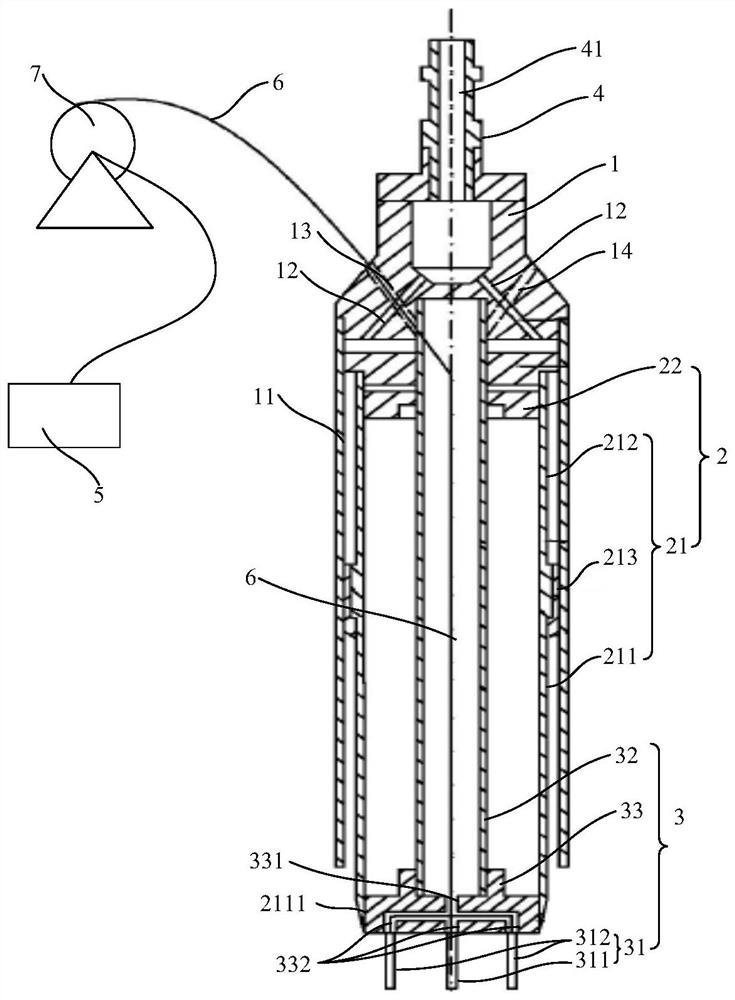

Inlet pressurized two-dimensional double piston pump

ActiveCN107795447BIncrease pressureEliminate cavitationPositive displacement pump componentsPiston pumpsReciprocating motionEngineering

The invention discloses an inlet pressurizing type two-dimensional duplex piston pump comprising a pump body. The pump body is provided with an oil suction opening and an oil discharge opening. A pumpunit is arranged in the pump body and comprises two cylinder blocks fixed into the pump body. The two cylinder blocks are arranged in the left-right direction. Pistons are both arranged in the two cylinder blocks, and the two pistons are in mutual linkage. The center axis of each cylinder block coincides with the center axis of the corresponding piston. The two ends of each piston are both provided with moving components, wherein the moving components drive the piston to axially move so as to cause the volume of a work cavity to change. The piston motion driving directions of the two moving components at the two ends of each piston are opposite. Each piston, the corresponding cylinder block and the moving components on the two sides of the piston constitute one half part of the duplex structure of the piston pump, the part close to a front end cover is the upper half part of the duplex structure of the piston pump, and the part close to a back end cover is the lower half part of the duplex structure of the piston pump. According to the inlet pressurizing type two-dimensional duplex piston pump, the double-freedom-degree structure of rotation and sliding of the pistons is used forreplacing an oil distributing disk structure of a traditional circumferential plunger pump, and continuous oil suction and discharge functions are achieved; besides, the duplex mode is adopted, if thepistons rotate for one circle, reciprocating motion is conducted four times, oil suction and oil discharge are each conducted eight times, and the number of times of oil suction and the number of times of oil discharge are each four larger than those of a monoblock piston pump.

Owner:ZHEJIANG UNIV OF TECH

Window frame to prevent dust from entering the chute

ActiveCN106837086BRunning poorlyAvoid enteringWing arrangementsSpecial door/window arrangementsEngineeringElectrical and Electronics engineering

Owner:盐城新汇村镇建设发展有限公司

Washing equipment

PendingCN110192831ANeat and beautiful interior layoutSliding effectFootwear cleanersEngineeringConductor Coil

Owner:QINGDAO HAIER WASHING MASCH CO LTD

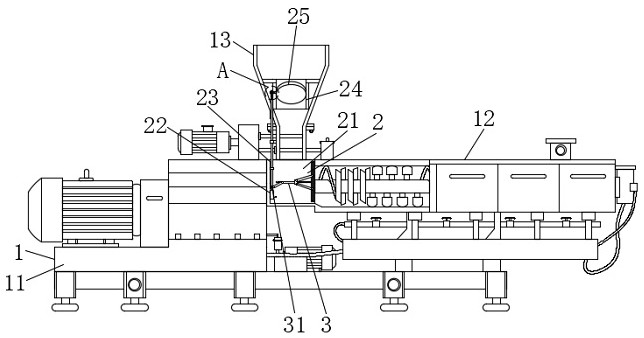

A high-torque co-rotating parallel twin-screw extruder

The invention relates to the technical field of extruders, in particular to a high-torque co-rotating parallel twin-screw extruder, which includes a body, the body includes a frame, the surface of the frame is fixedly connected with a discharge bin, and the discharge bin is fixedly connected to the surface of the frame. The surface of the silo is fixedly connected with a material inlet, and the inner side of the discharge silo is provided with a storage mechanism, and the storage mechanism includes a storage silo, and the inner side of the discharge silo is fixedly connected with a storage silo. The surface of the storage bin is fixedly connected with a chute, and the inner side of the chute is slidably connected with an adjusting rod. In the present invention, through the sliding and telescopic adjustment of the adjusting rod, the rack drives the rotating gear to rotate, thereby facilitating the rotating gear to drive the rotation of the material control plate at the material control port. After the rotation angle of the material control plate is changed, it is convenient to control the flow rate of the material in the feed port. And the control of the material volume makes the storage material inside the equipment to be replenished independently, and the linkage between the baffle plate and the control panel is realized through the sliding of the control panel, and then the material in the storage bin is automatically conveyed.

Owner:南京金吉机械设备有限公司

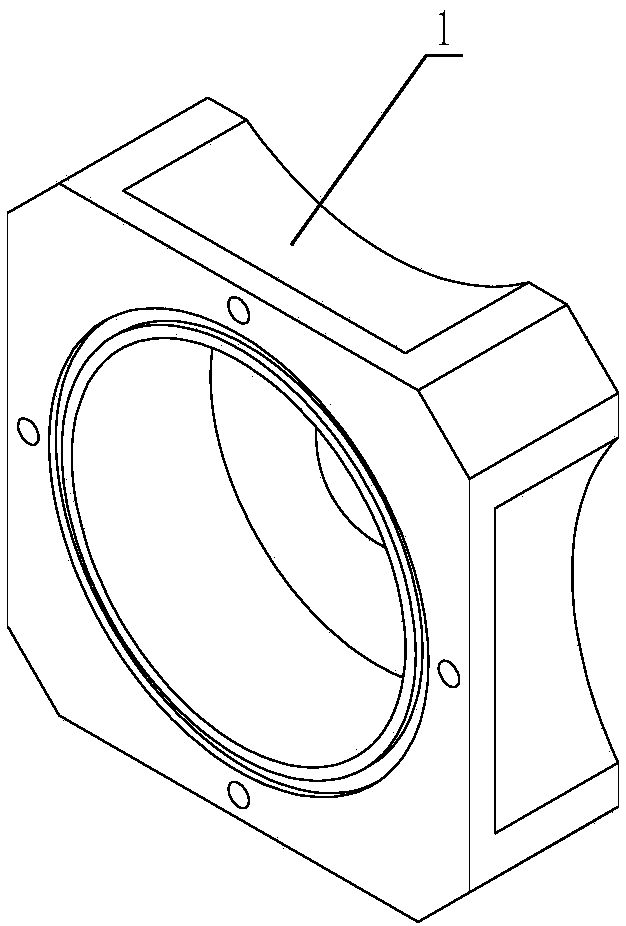

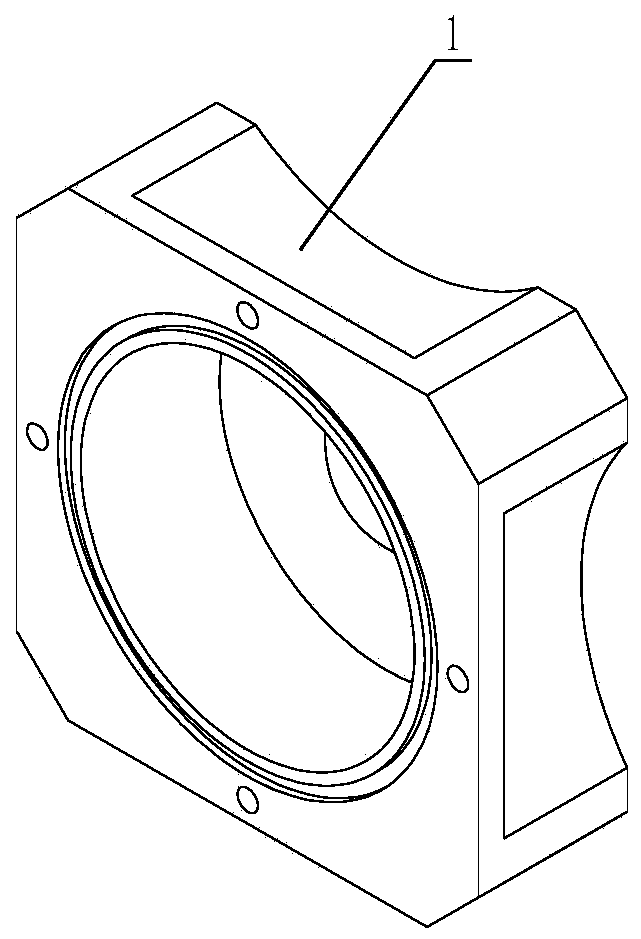

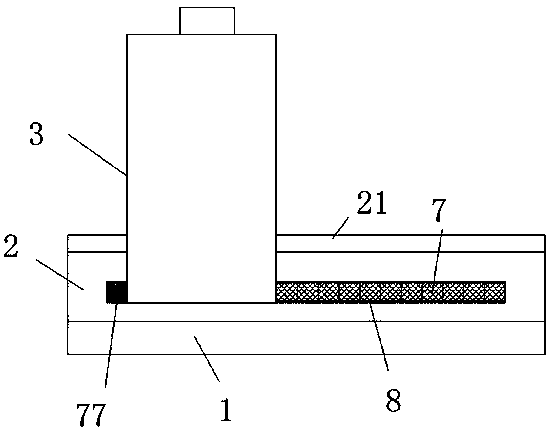

Hydraulic transmission system and reversing valve thereof

ActiveCN102494158ASimple structureReduce the difficulty of manipulationOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanical engineering

The invention discloses a hydraulic reversing valve, which comprises a valve body (1), a valve core (2) arranged in the valve body (1) in a rotatable manner and an operating rod (3) for driving the valve core (2) to rotate in the valve body (1), wherein a hollow cavity and at least three first oil feed holes (21) are formed in the valve core (2); at least two second oil feed holes (4) are formed in the valve body; and any one of the first oil feed holes is selectively connected with or disconnected from any one of the second oil feed holes (4) through rotation of the valve core (2). The operating rod drives the valve core to move, so that switching among at least six oil paths is realized, and the structure is simple. The invention also discloses a hydraulic transmission system comprisingthe reversing valve.

Owner:SANY AUTOMOBILE MFG CO LTD

Positioning gripper with self-cleaning function

ActiveCN110181290BSliding effectAchieve positioningLarge fixed membersMaintainance and safety accessoriesForeign matterFriction loss

The invention relates to the technical field of machine tools, in particular to a positioning clamp device with an automatic cleaning function. A clamping block arranged on the inner wall of a slidingblock in a sliding manner is included, wherein the sliding block is used for being connected with a guide rail. The clamping block is connected with a drive mechanism for driving the clamping block to slide. The front end, in the motion direction, of the sliding block is provided with a cleaning block which is in sliding connection with the guide rail. The inner wall of the cleaning block is provided with a wiping piece for wiping the guide rail. The positioning clamp device solves the problems that in the prior art, foreign matter on a guide rail is clamped between a sliding block and the guide rail, sliding block sliding is influenced, and consequently the sliding block and guide rail friction losses are large.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

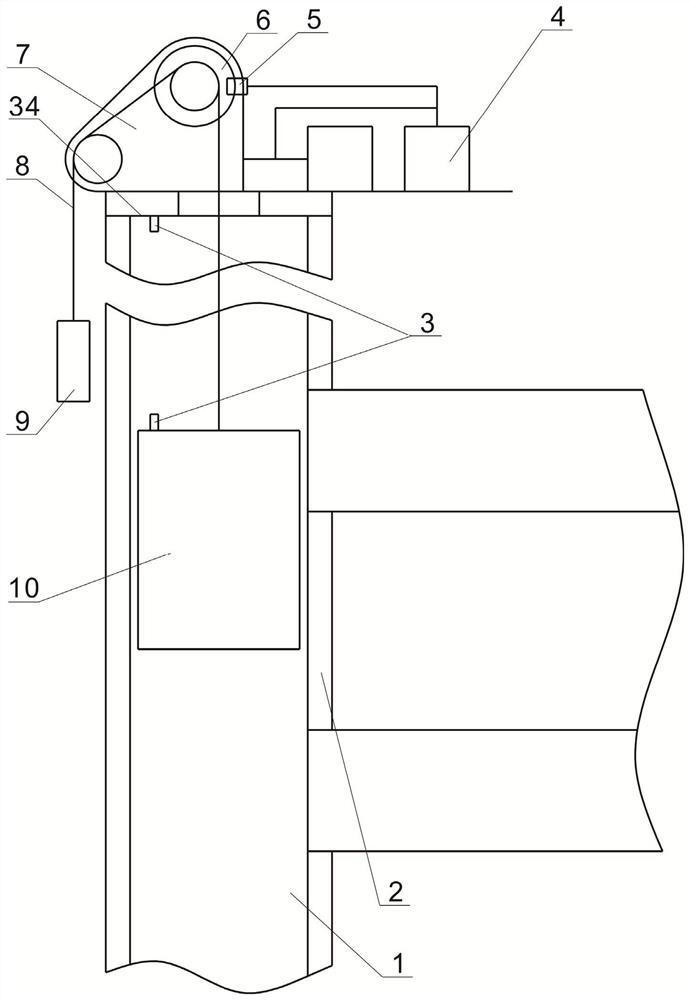

Elevator for rescue and control method thereof

The invention discloses an elevator for rescue and a control method thereof.The elevator comprises an escape exit, a first photoelectric sensor, a second photoelectric sensor, a first ladder stand assembly, a second ladder stand assembly, a landing door opening and closing assembly, a controller and an ARD emergency rescue device, and the controller is electrically connected with a car door opening and closing assembly, the first photoelectric sensor and the second photoelectric sensor; the ARD emergency rescue device is electrically connected with the controller, the lift car lifting assembly, the landing door opening and closing assembly, the computer terminal and the external power grid. The control method comprises steps S1 to S5. When power failure occurs, the lift car runs to the leveling position, the car door and the hoistway door are opened, and passengers escape; when the lift car cannot normally lift or the car door cannot be opened, the hoistway door suitable for passengers to escape is automatically opened, and the passengers are prompted to escape; in addition, the first crawling ladder assembly and the second crawling ladder assembly are both of a pure mechanical structure, the structure is simple, operation is convenient, and escape of passengers is facilitated.

Owner:浙江速捷电梯有限公司

Crawler-type chassis telescopic mechanism

InactiveCN102019971BPrevent left and right movementPrevent deviationEndless track vehiclesRolling chassis

Owner:SANY HEAVY MACHINERY

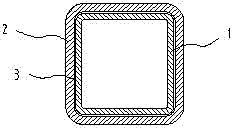

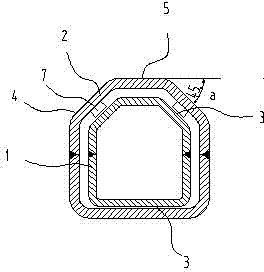

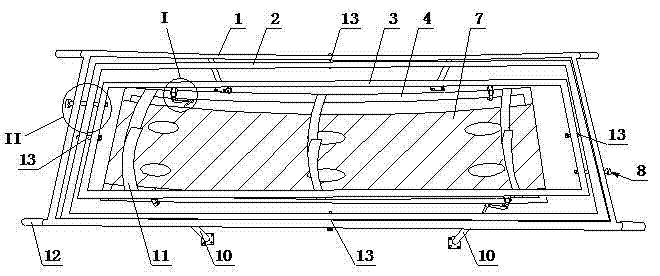

Self-balancing stretcher

InactiveCN101947165BAutomatically adjust balanceImprove shock absorptionStretcherComputer engineering

The invention relates to a self-balancing stretcher. The stretcher comprises a first framework layer, wherein a second framework layer and a third framework layer are arranged on the inner side of the first framework layer in turn; two support rods in a length direction or a width direction of the second framework layer are rotatably connected with two support rods on the first framework layer respectively, and the other two support rods on the second framework layer are rotatably connected with two support rods on a third framework layer; the connection joints of the first framework layer, the second framework layer and the third framework layer are positioned in the center of the support rods to which the connection joints belong respectively; a sliding mechanism is arranged on two support rods in the length direction of the third framework layer respectively; the third framework layer is in sliding connection with a fourth framework layer by the sliding mechanism; two support rods on the fourth framework layer which are connected with the third framework layer are arc-shaped; fastening bolts are arranged on the sliding mechanism; and the inner side of the fourth framework layeris connected with a bed surface. The stretcher of the invention has the advantages of high vibration damping performance, capacity of automatically adjusting the balance, simple structure, convenientand flexible use and low cost.

Owner:CHONGQING UNIV OF TECH

power tool

ActiveCN104942770BSliding effectEffective and regularPortable power-driven toolsElectricityMotor drive

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

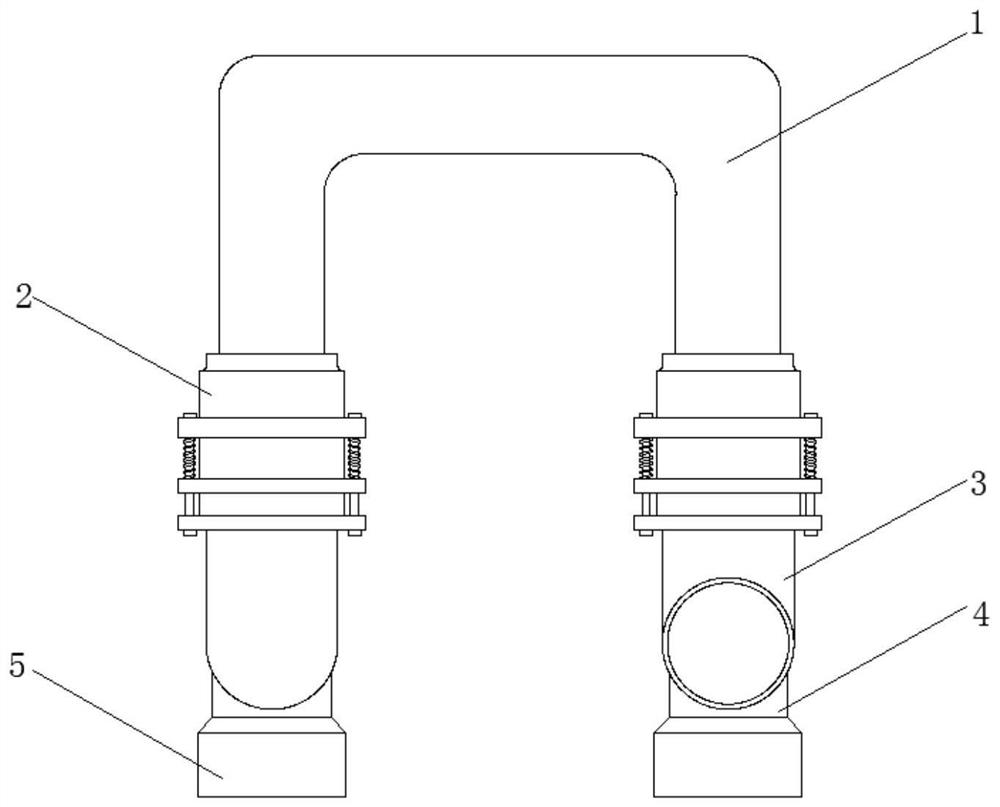

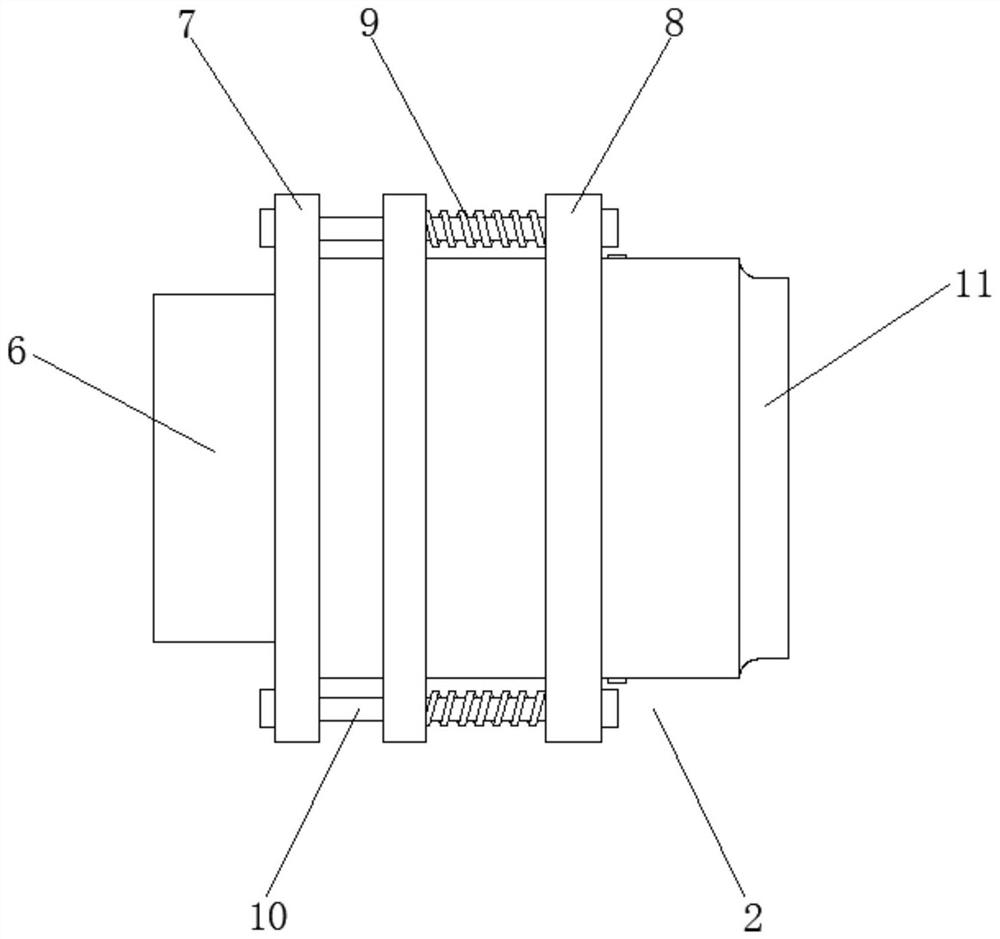

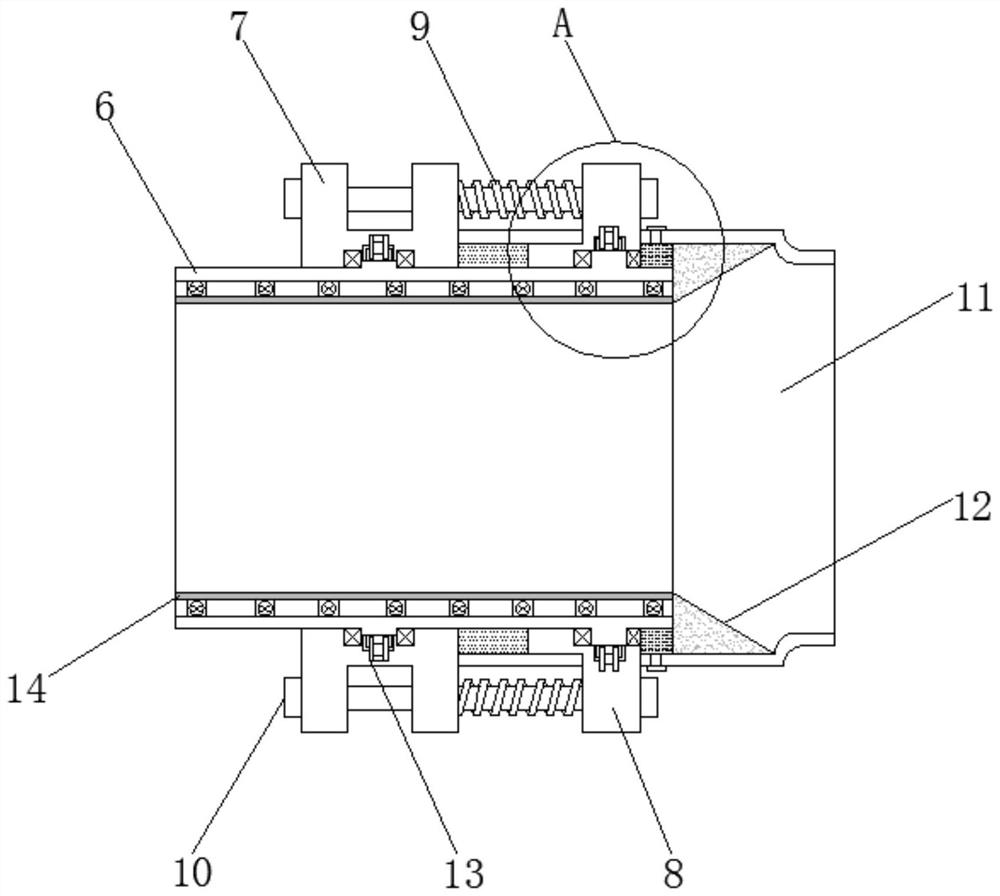

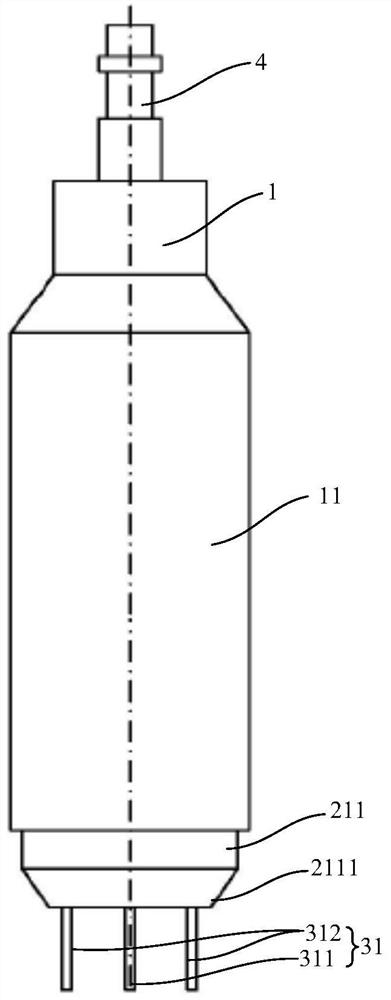

A rotary compensator with flexible rotation and high pressure resistance

ActiveCN112197087BImprove rotational flexibilitySmooth rotationPipeline expansion-compensationAdjustable jointsEngineeringPhysics

Owner:江苏恒昌波纹管有限公司

Floating two-dimensional double piston pump

ActiveCN107781125BSimple structureRealize continuous oil suction and discharge functionPositive displacement pump componentsPiston pumpsEngineeringOil distribution

Owner:ZHEJIANG UNIV OF TECH

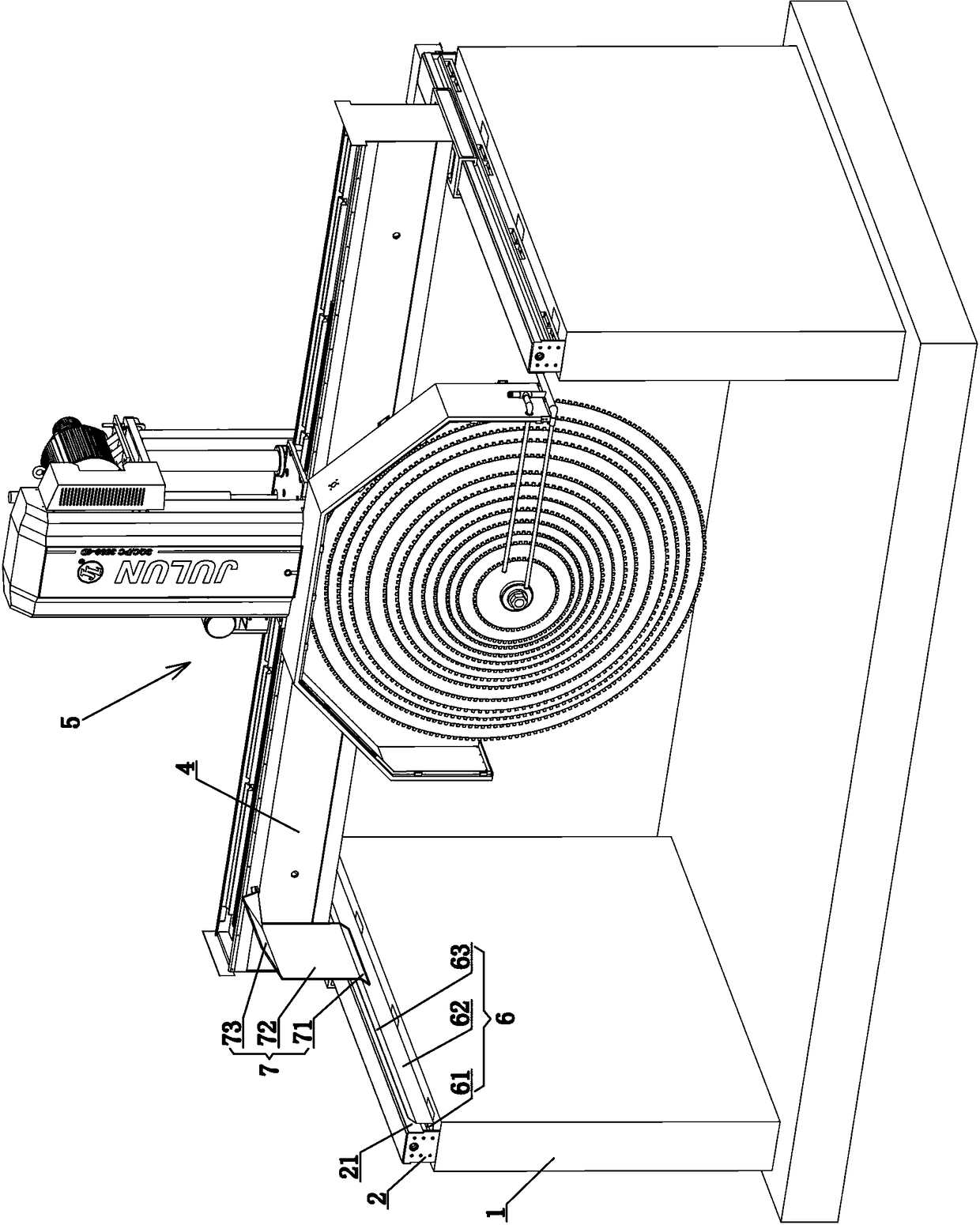

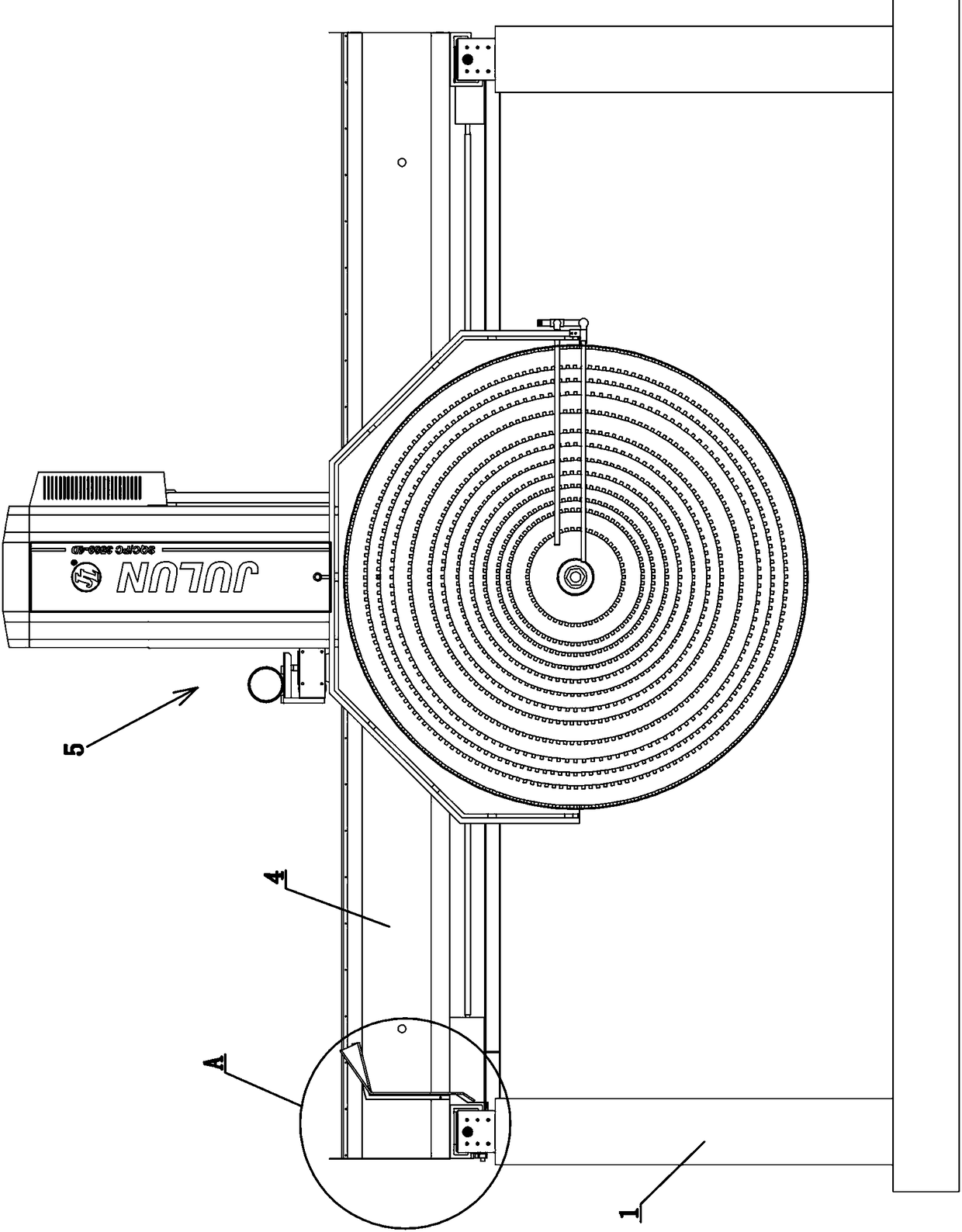

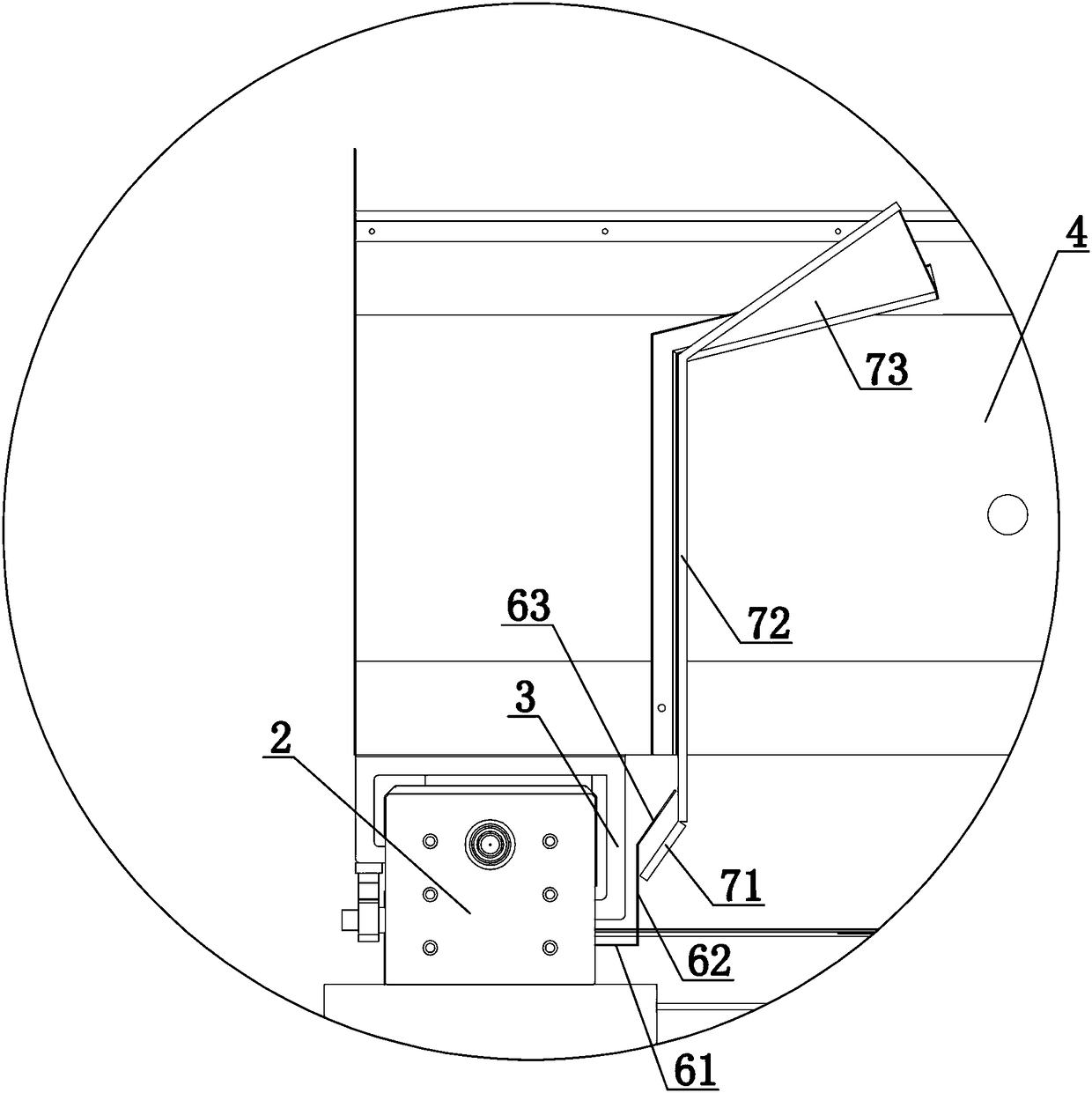

a bridge stone cutter

ActiveCN107009520BAvoid enteringSolve the problem of accessing the inside of the side beam ramWorking accessoriesStone-like material working toolsBridge typeArchitectural engineering

The invention discloses a novel bridge type stone cutting machine. The novel bridge type stone cutting machine comprises a base, edge beams arranged on the base, edge beam rams which are respectively arranged on the edge beams, a transverse beam connected with the edge beam rams, and a host device arranged on the transverse beam, wherein an edge beam protection hood covers the top of each edge beam along the length direction of the edge beam; a first water retaining hopper is arranged on the inner side of each edge beam along the length direction of the edge beam; a second water retaining hopper is located on the front end surface of the transverse beam, and is located on the inner side of the corresponding first water retaining hopper; each first water retaining hopper comprises a first transverse plate, a first vertical plate, and a first oblique plate; one end of each first transverse plate is fixedly connected with the inner side surface of the corresponding edge beam; the other end of each first transverse plate is fixedly connected with the bottom end of the corresponding first vertical plate; the top end of each first vertical plate is fixedly connected with the bottom end of the corresponding first oblique plate; the lower part of each edge beam ram is located in the space enclosed by the corresponding first transverse plate and the corresponding first vertical plate; the bottom of the second water retaining hopper is located on the right side of the corresponding first vertical plate; and the height of the second water retaining hopper is higher than that of the corresponding edge beam ram.

Owner:福建省南安市巨轮机械有限公司

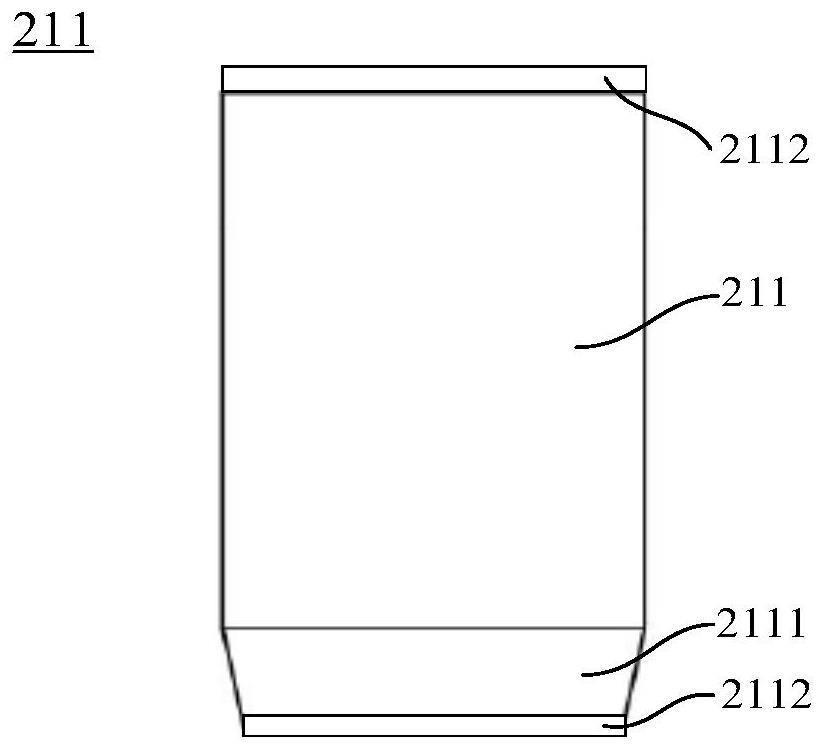

Thin-wall soil sampler capable of measuring water content of soil sample

PendingCN114199613ASliding effectWithdrawing sample devicesMoisture content investigation using microwavesSoil scienceEnvironmental engineering

The embodiment of the invention discloses a thin-wall soil sampler capable of measuring the water content of a soil sample, relates to the technical field of geotechnical engineering investigation equipment, and solves the problem of low water content measurement and soil sample collection quality of a soil sampler. The thin-wall soil sampler capable of measuring the water content of the soil sample comprises a base, a soil sampling assembly and a detection assembly, the first end of the base is used for being connected with a drill rod, and the second end of the base is provided with a limiting pipeline. The soil sampling assembly comprises a soil sampling pipe, the soil sampling pipe is consistent with the limiting pipeline in extension direction and located in the limiting pipeline, and the soil sampling pipe is slidably connected with the limiting pipeline through a first sliding mechanism; the detection assembly is located in the soil sampling pipe, is in sliding connection with the soil sampling pipe through a second sliding mechanism and comprises a water content detection part and a supporting rod, the first end of the supporting rod is fixedly connected with the second end of the base, the second end of the supporting rod is fixedly connected with the water content detection part, and the second end of the supporting rod is close to the end, away from the base, of the soil sampling pipe. The thin-wall soil sampler capable of measuring the water content of the soil sample is used for sampling the soil sample and measuring the water content of a soil body.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Welding equipment

InactiveCN108080845AImprove stabilityImprove airtightnessWelding/cutting auxillary devicesAuxillary welding devicesSoldering gunEngineering

The invention discloses welding equipment. The welding equipment comprises a welding frame and a sliding frame connected with the welding frame in a sliding and cooperating mode; a base is arranged atthe bottom of the welding frame, and a sliding groove which enables the left side and the right side of the welding frame to communicate with each other is formed in the welding frame; and the sliding frame comprises a bottom arm, a left arm and a right arm, wherein the bottom arm is connected with the sliding groove in a sliding and cooperating mode, the left arm is arranged at the left end of the bottom arm and is connected with the left end face of the welding frame in a sliding and cooperating mode, and the right arm is arranged at the right end of the bottom arm and is connected with theright end face of the welding frame in a sliding and cooperating mode. According to the welding equipment, the overall structure is simple, the production cost is relatively low, and operation is simple and convenient; the front-and-back movement of a welding gun is driven by power provided by front-and-back electric rotating machines through working, and the up-and-down movement of the welding gun is driven by power provided by up-and-down electric rotating machines through working, so that stability of a plate during welding is guaranteed, and the welding gun is guaranteed not to deviate when being used for welding the plate; and therefore, the welding equipment is good in welding effect and suitable for popularization and use.

Owner:惠安县南兴电子科技有限公司

Novel welding device

InactiveCN108080823AImprove stabilityImprove airtightnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a novel welding device. The novel welding device comprises a welding frame and a sliding frame connected with the welding frame in a sliding and cooperating mode; a base is arranged at the bottom of the welding frame, and a sliding groove which enables the left side and the right side of the welding frame to communicate with each other is formed in the welding frame; and the sliding frame comprises a bottom arm, a left arm and a right arm, wherein the bottom arm is connected with the sliding groove in a sliding and cooperating mode, the left arm is arranged at the leftend of the bottom arm and is connected with the left end face of the welding frame in a sliding and cooperating mode, and the right arm is arranged at the right end of the bottom arm and is connectedwith the right end face of the welding frame in a sliding and cooperating mode. According to the novel welding device, the overall structure is simple, the production cost is relatively low, and operation is simple and convenient; the front-and-back movement of a welding gun is driven by power provided by front-and-back electric rotating machines through working, and the up-and-down movement of the welding gun is driven by power provided by up-and-down electric rotating machines through working, so that stability of a plate during welding is guaranteed, and the welding gun is guaranteed not todeviate when being used for welding the plate; and therefore, the novel welding device is good in welding effect and suitable for popularization and use.

Owner:惠安县南兴电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com