a bridge stone cutter

A stone cutter and bridge-type technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problem that dust cannot be completely blocked, and achieve the effect of novel structure, ingenious design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

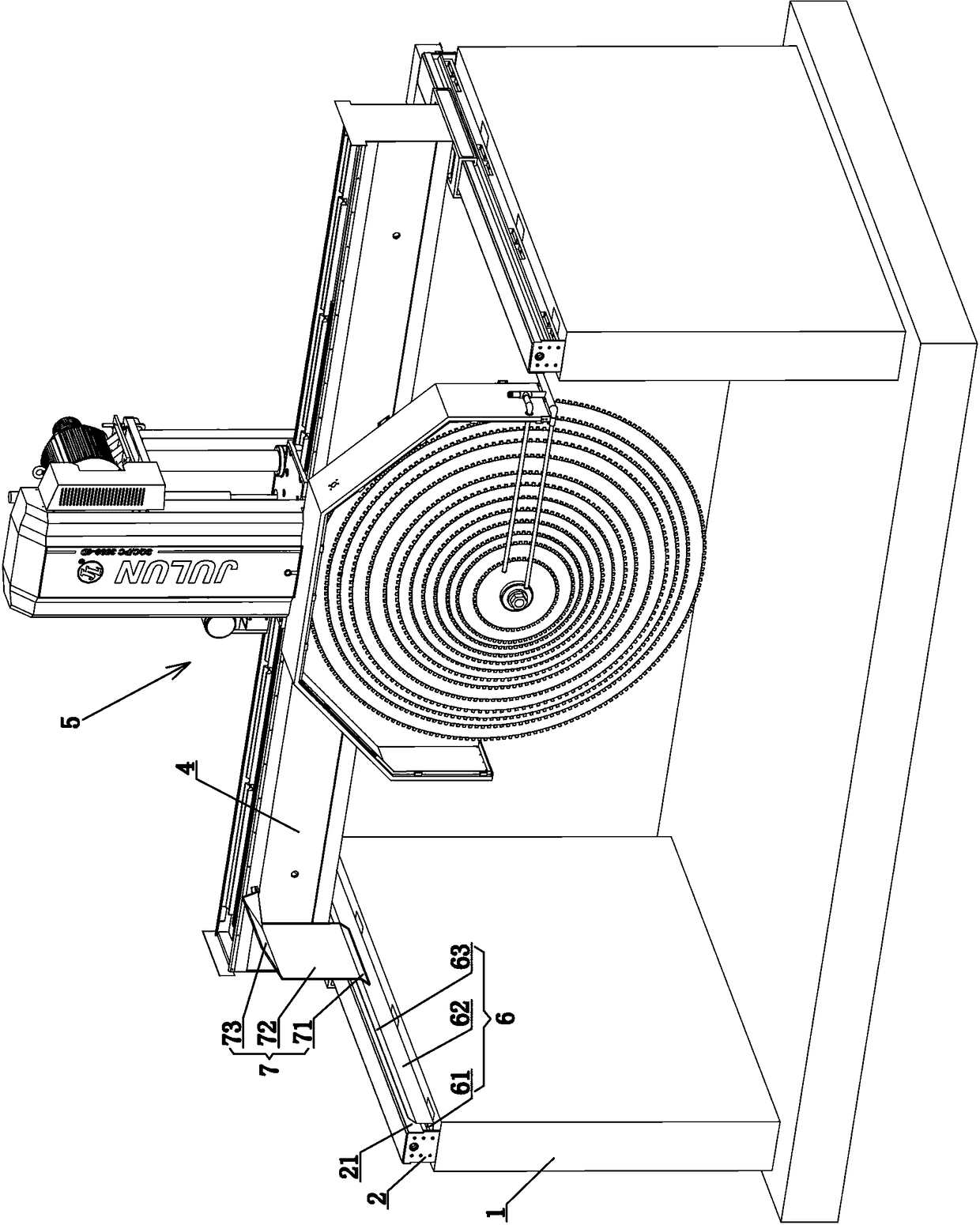

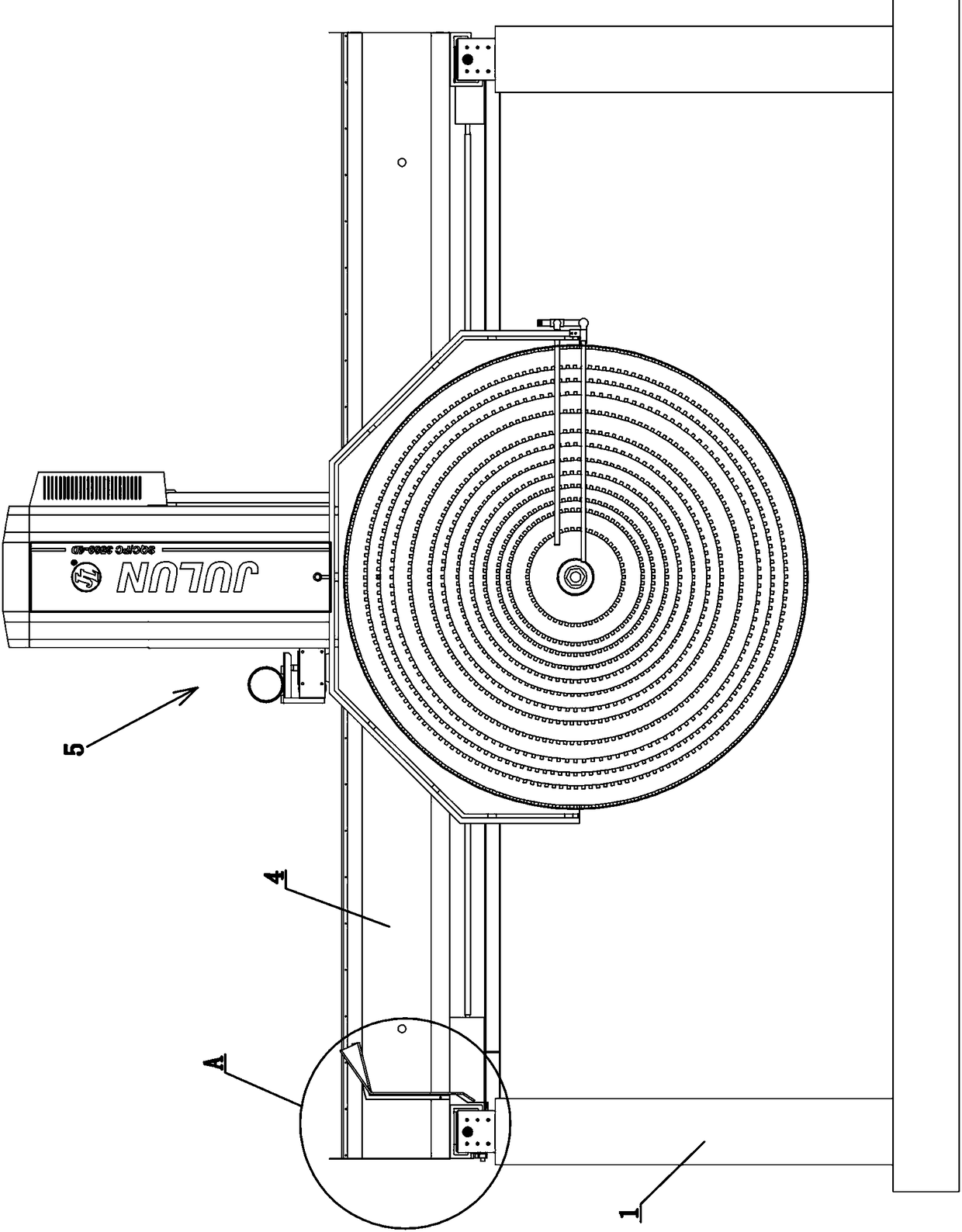

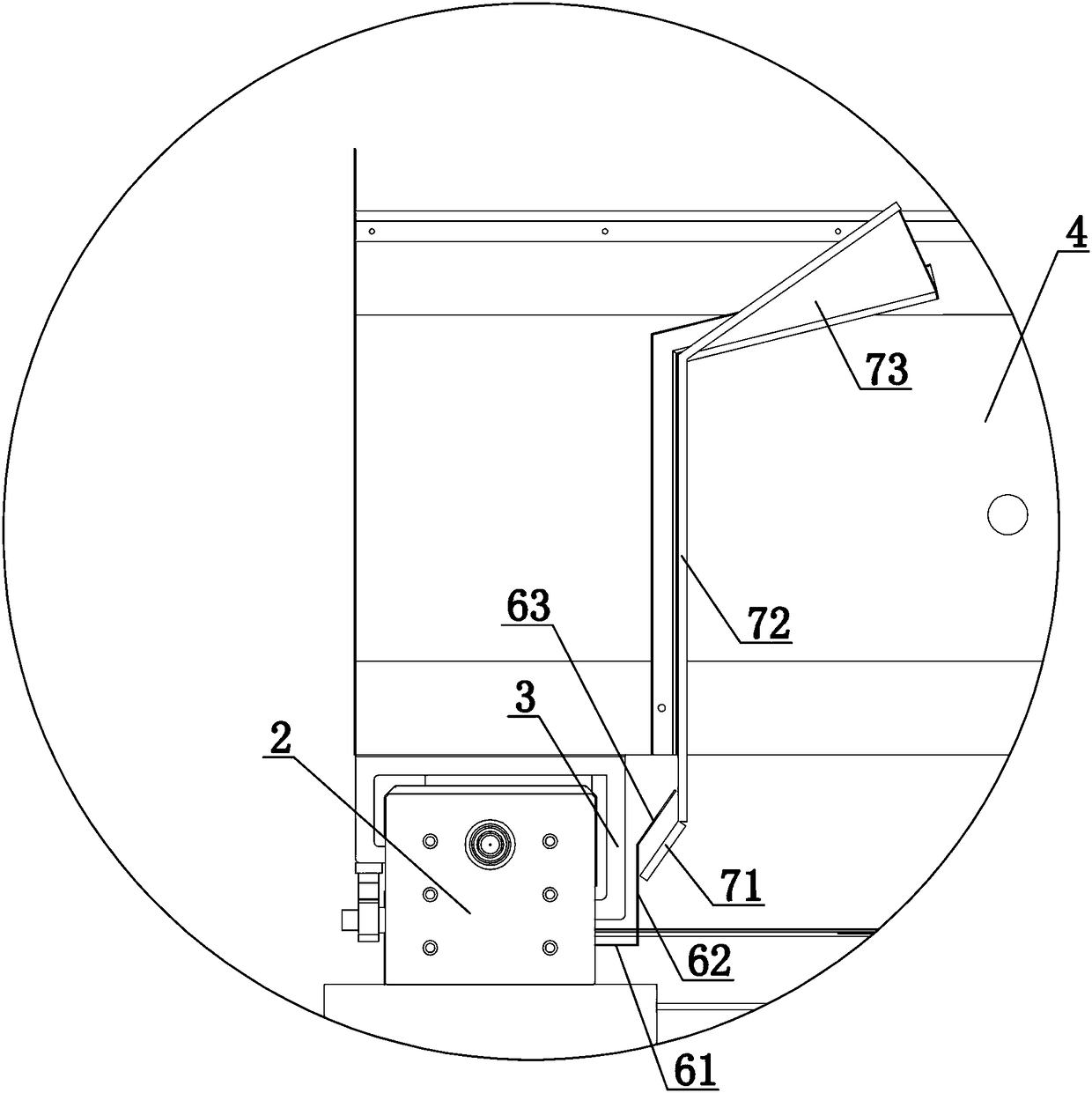

[0017] refer to Figure 1 to Figure 3 . A bridge-type stone cutter, comprising a base 1, a side beam 2 arranged on the base 1, a side beam ram 3 arranged on the side beam 2, a beam 4 connected to the side beam ram 3, and a 4 on the host device 5 . The top of the side beam 2 is covered with a side beam shield 21 along its length direction; A second water retaining bucket 7 is provided, and the second water retaining bucket 7 is located inside the first water retaining bucket 6 . The first water retaining bucket 6 includes a first horizontal plate 61 , a first vertical plate 62 and a first inclined plate 63 , one end of the first horizontal plate 61 is fixedly connected to the inner surface of the side beam 2 , and the first horizontal plate The other end of the plate 61 is fixedly connected to the bottom end of the first vertical plate 62 , and the top end of the first vertical plate 62 is fixedly connected to the bottom end of the first inclined plate 63 . The lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com