Power tool

A technology for a power tool and a winding column, which is applied in the field of power tools, can solve the problems of inconvenient use, lack of consideration, and inconvenient machining of workpieces, and achieves the effects of convenient use and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

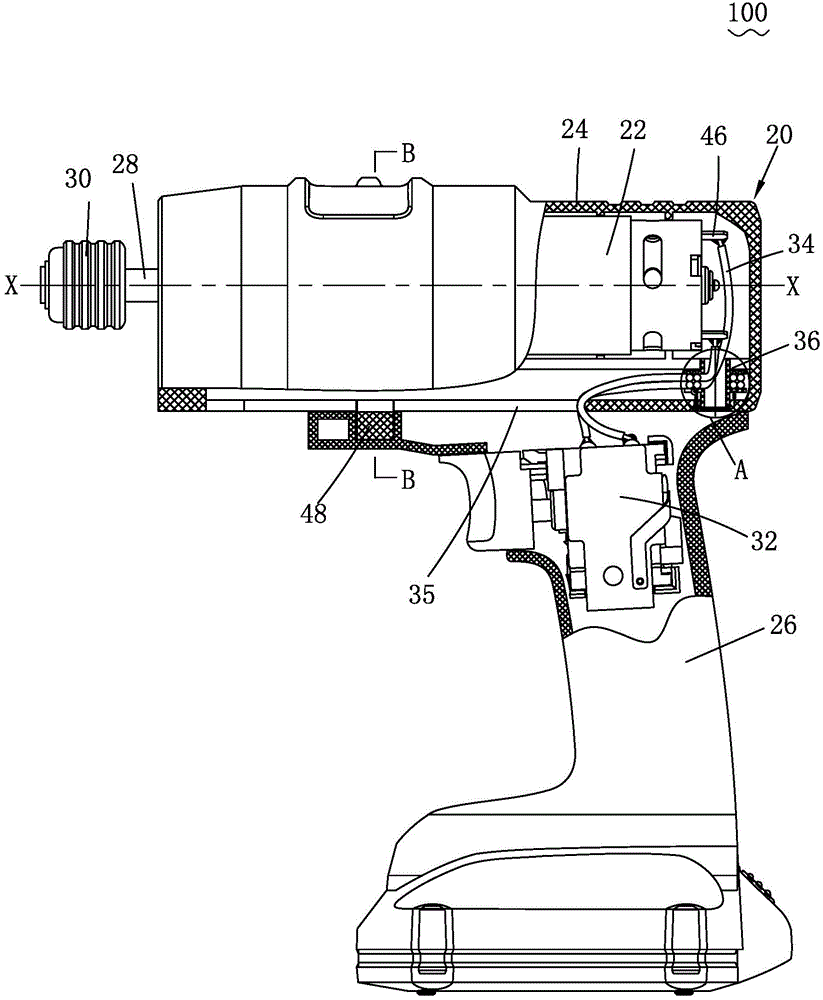

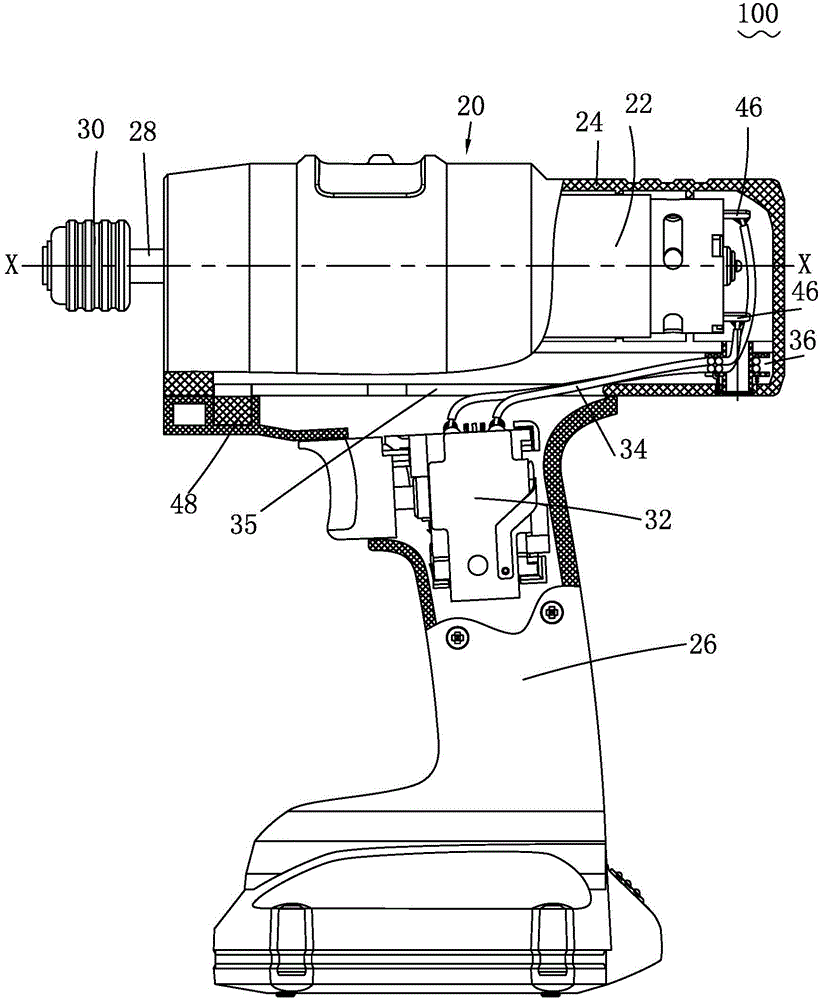

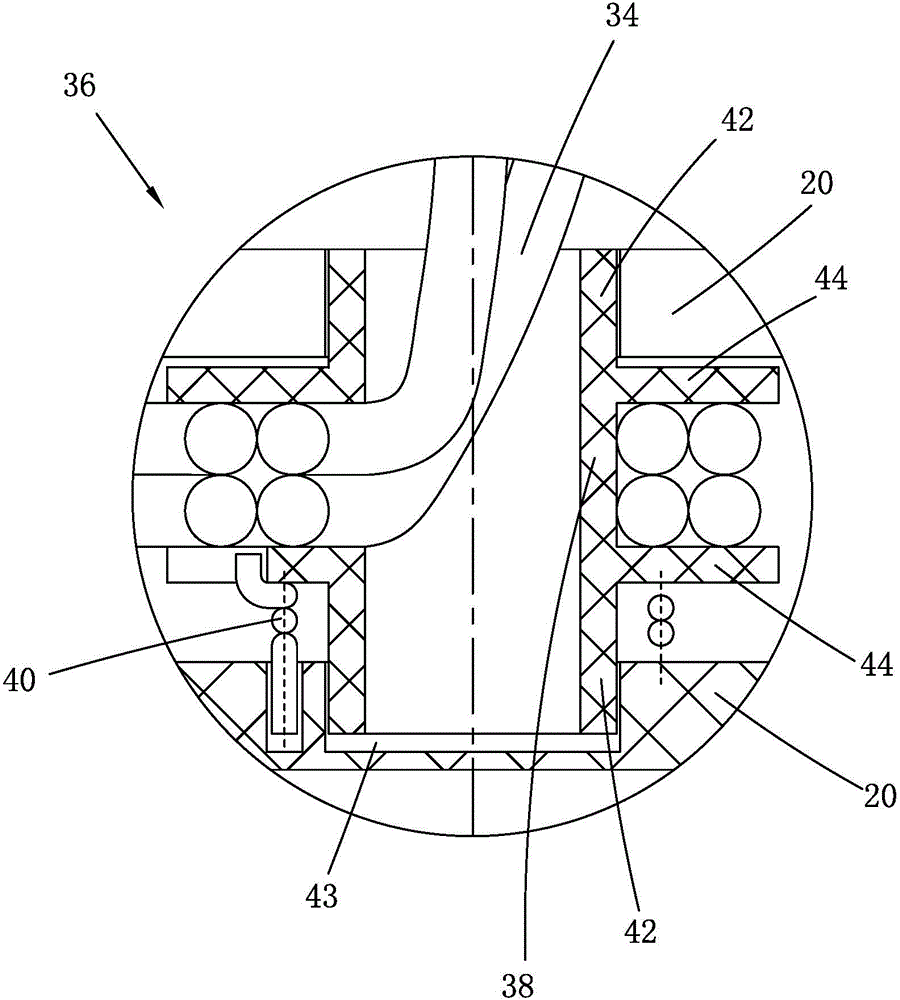

[0036] See figure 1 and figure 2 The power tool 100 of this embodiment includes a casing 20, the casing 20 includes a casing 24 for accommodating the motor 22, and a handle 26 connected to the casing 24. The output shaft of the motor 22 drives the output rod 28 to move through a transmission mechanism. A collet 30 on which a working head (not shown) can be mounted is fixedly connected to the output rod 28 . When the power tool 100 is in use, the motor 22 drives the working head to move through the transmission mechanism, the output rod 28 and the collet 30 to process the workpiece.

[0037] The output shaft of the motor 22 has an axis X-X, and the output rod 28 has a center line. In this embodiment, the axis X-X of the output shaft of the motor 22 coincides with the center line of the output rod 28, so that the power tool 100 has a compact structure.

[0038] The handle 26 and the casing 24 are slidably coupled along the extension direction of the axis X-X of the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com