Positioning gripper with self-cleaning function

An automatic cleaning and gripper technology, applied in the field of machine tools, can solve the problems affecting the sliding of the slider, the friction loss of the slider and the guide rail, etc., and achieve the effect of saving power resources, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

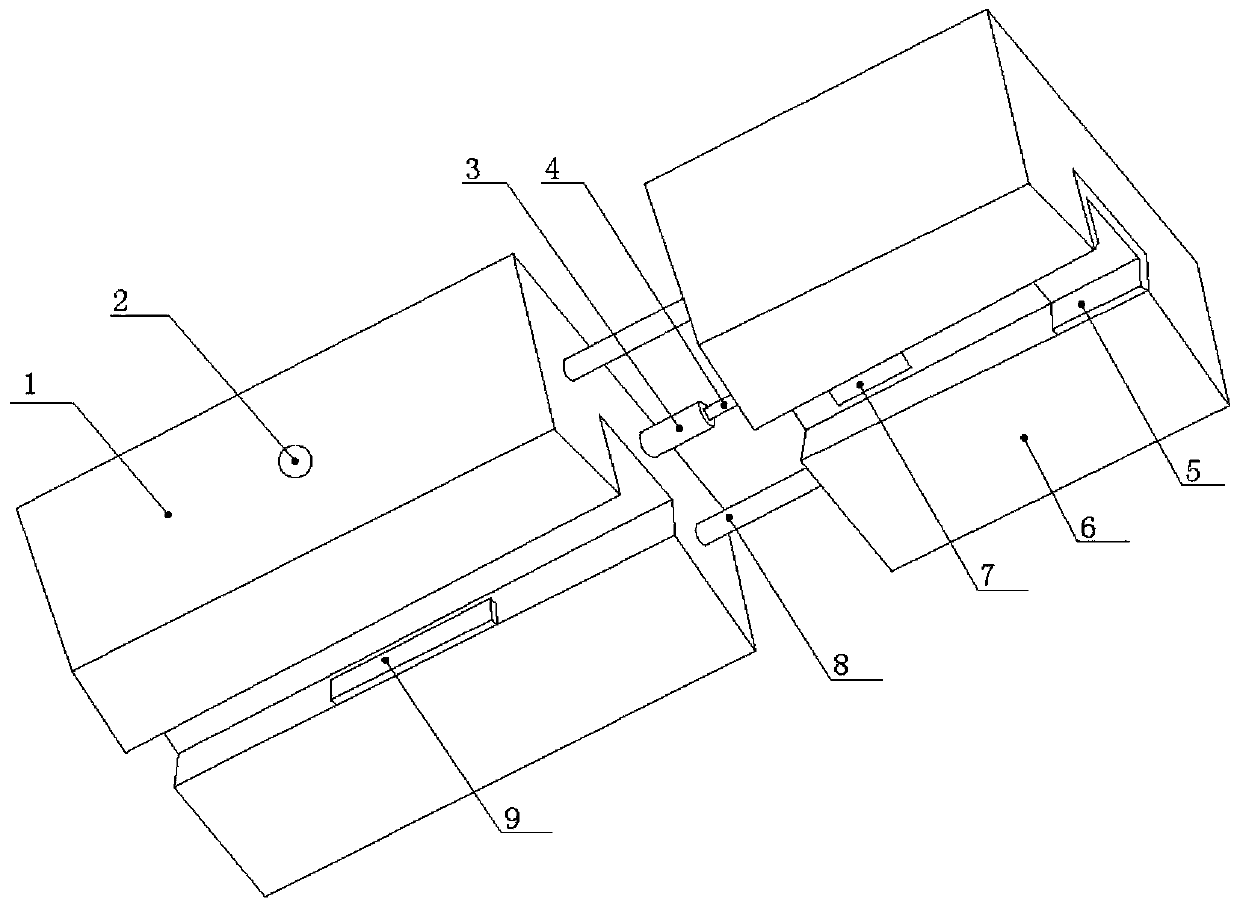

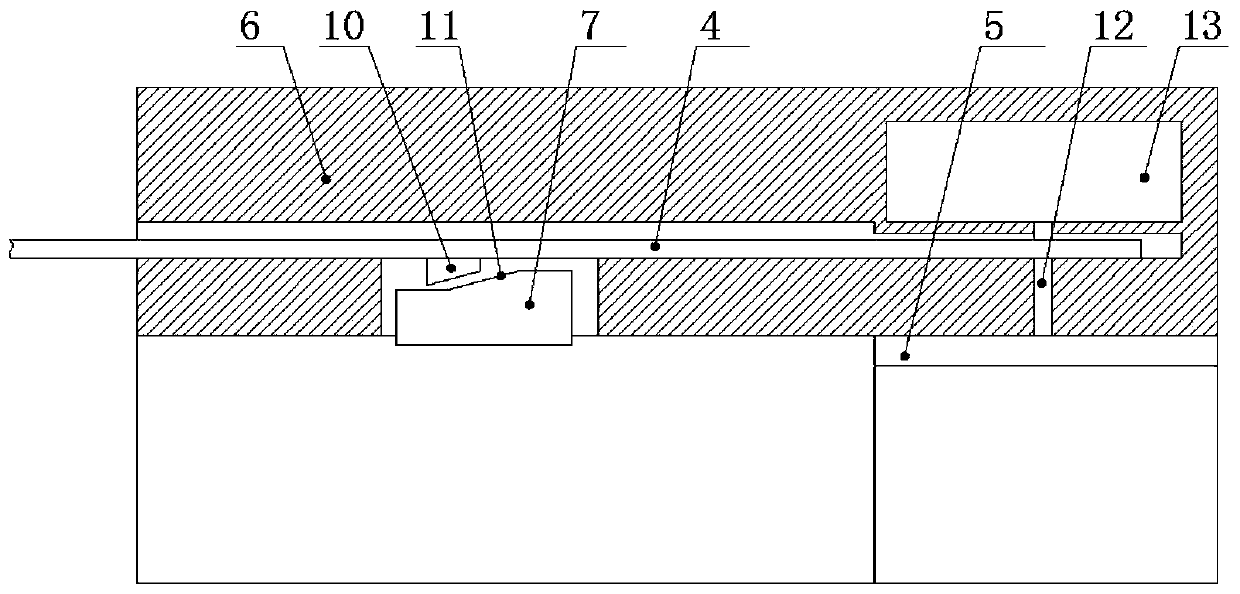

[0022] Such as figure 1 As shown, the positioning holder with automatic cleaning function includes a clamping block, and the clamping block is slidably arranged on the inner wall of the slider 1 for connecting with the guide rail. The structure of slider 1 is as follows figure 1 As shown, the bottom of the slider 1 is provided with a chute that cooperates with the guide rail. Clamping blocks 9 are slidably connected to the inner walls on both sides of the slider 1 . Both clamping blocks 9 are connected with a driving mechanism for driving them to slide. In this embodiment, the driving mechanism includes a main oil pipe 2 installed in the slider 1, and one end of the main oil pipe 2 extends out of the slider 1 to connect to the hydraulic system. The clamping block 9 is slidably connected to the main oil pipe 2. Specifically, a piston can be sealed and slidably connected in the main oil pipe 2, and then the clamping block 9 is connected to the piston, and the piston slides in ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that both ends of the slider 1 are provided with a cleaning mechanism. With this arrangement, the saddle needs to move in the opposite direction, and the cleaning mechanism at the other end of the slider 1 can be used to realize automatic cleaning of the guide rail. . In addition, the sponge layer 5 in this embodiment is detachable. Specifically, the detachable setting of the sponge layer 5 can be realized by means in the prior art, such as glue bonding. So arranged, it is convenient to replace the sponge layer 5.

[0034] The present invention cleans the guide rail by setting cleaning mechanisms on both sides of the slider 1, which can prevent the foreign matter on the guide rail from being caught between the slider 1 and the guide rail and affect the movement of the slider 1, and at the same time prevent foreign matter from wearing the slider 1 and the guide rail. In addition, when the sponge layer 5 in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com