Machine tool part corner angle polishing operation device and polishing method

A technology for operating devices and parts, which is applied to the parts of grinding machine tools, grinding/polishing safety devices, and machine tools suitable for grinding the edge of workpieces, etc., which can solve the problems of wasting manpower and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

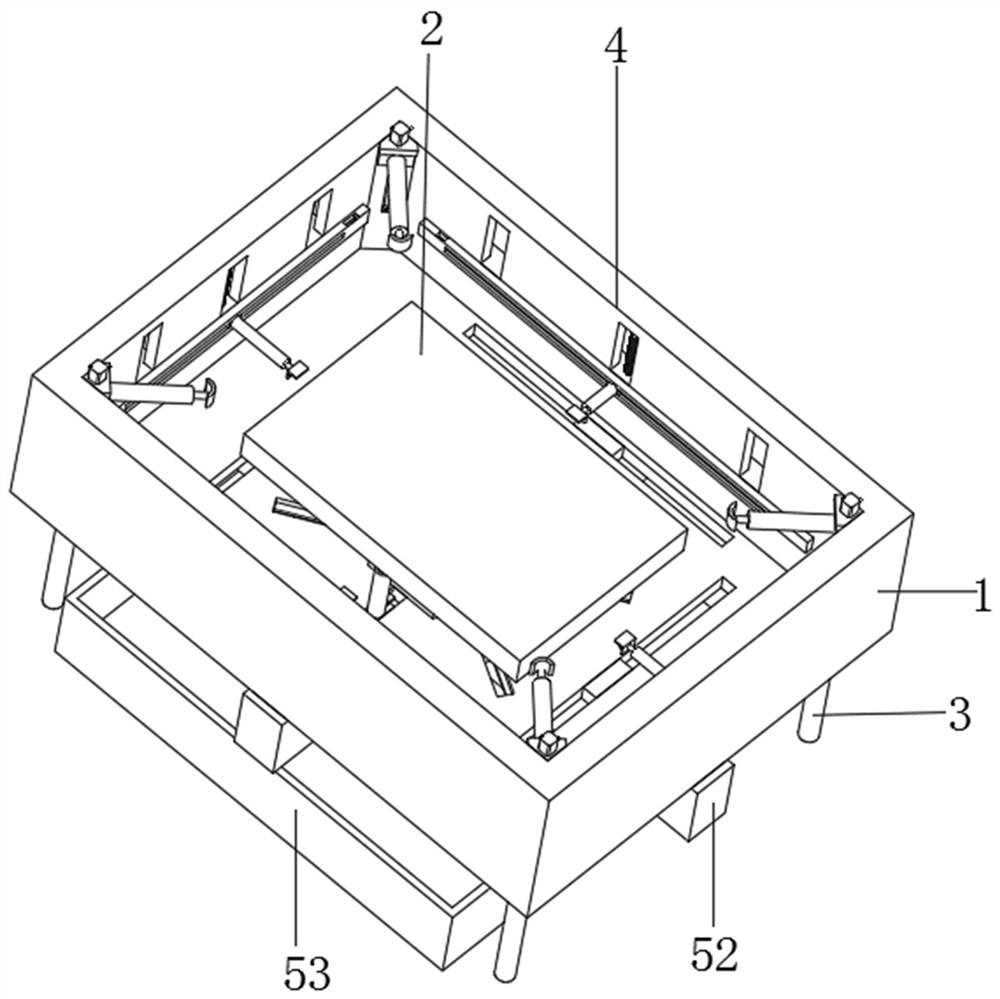

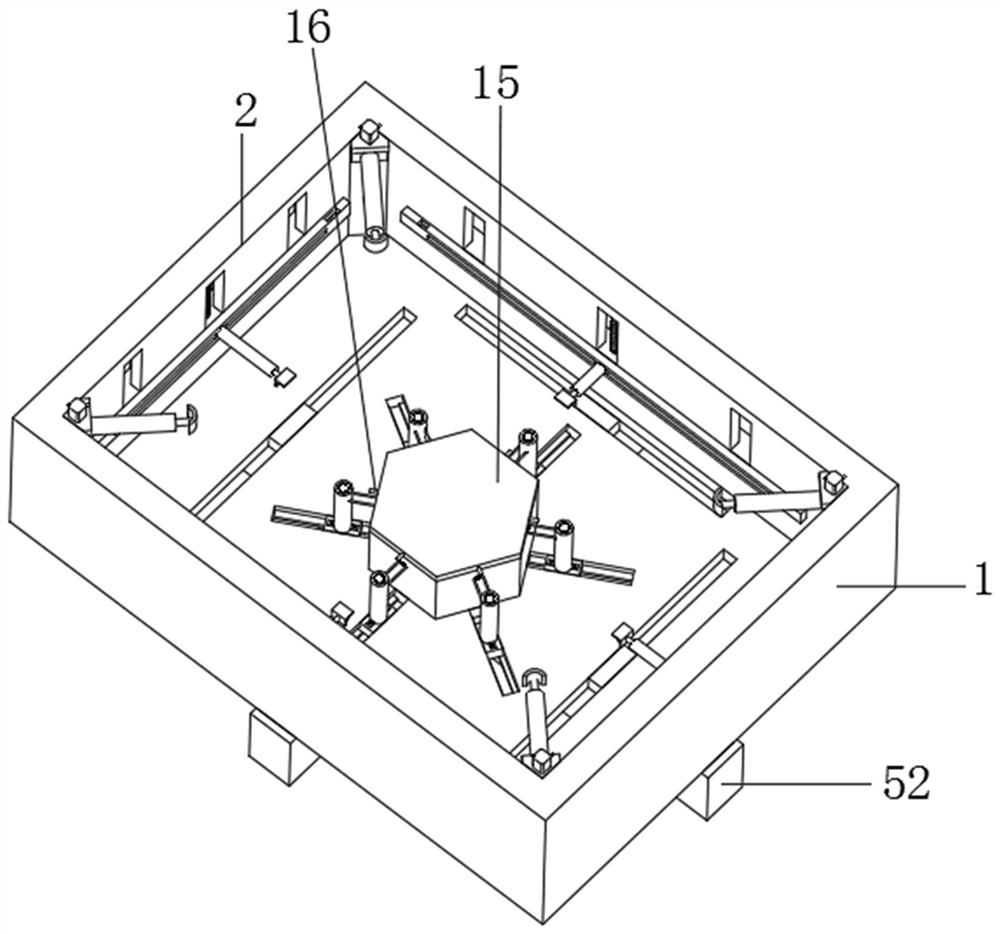

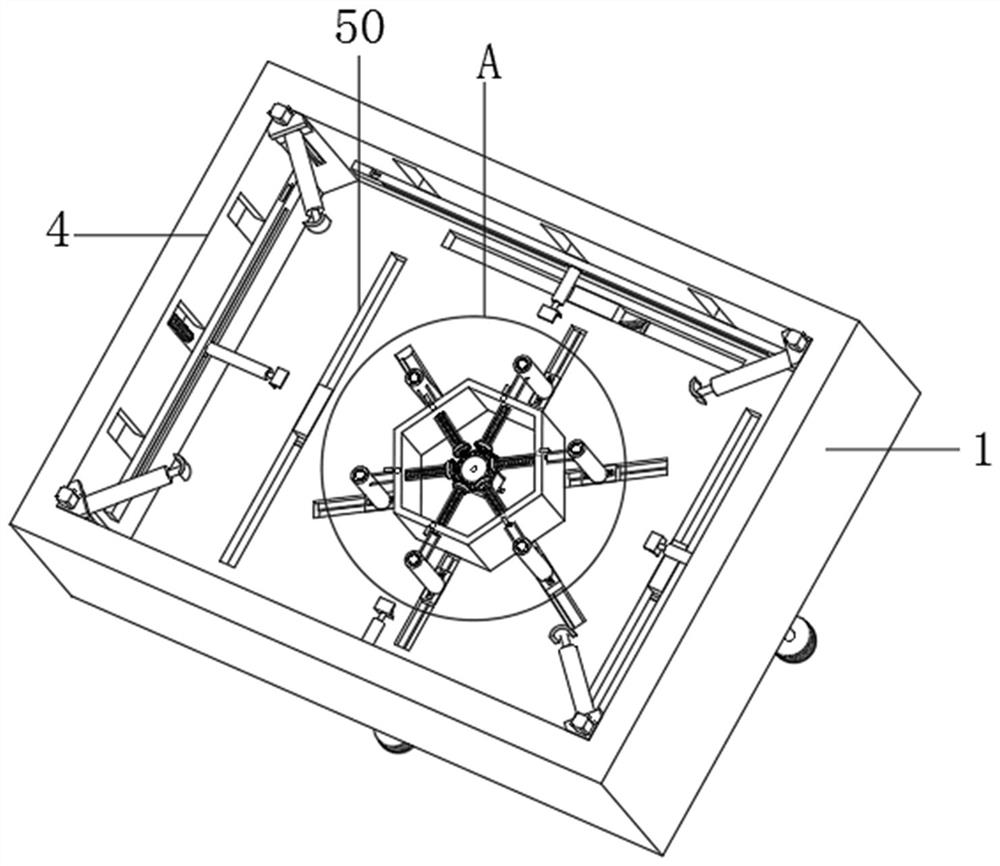

[0045] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 11 and Figure 14 As shown, the present invention provides the following technical solutions:

[0046] A device for polishing the edges and corners of machine tool parts, comprising a polishing base plate 1 and a machine tool part plate 2,

[0047] Among them, such as figure 1 and figure 2 As shown, the bottom end of the polishing substrate 1 is fixed with a support rod 3, the top center of the polishing substrate 1 is provided with a polishing rectangular groove 4, and the center of the bottom end of the polishing rectangular groove 4 is fixed with a six-sided cavity column 5, and the interior of the six-sided hollow column 5 is provided There are supporting and fixing components,

[0048] Among them, such as image 3 and Figure 4 As shown, the supporting and fixing assembly includes a servo motor 6, a central bevel gear 7, a side bevel ...

Embodiment 2

[0066] On the basis of Example 1, refer to figure 1 , Figure 4 and Figure 10 As shown, a device for polishing the edges and corners of machine tool parts:

[0067] The center of the bottom end of the polishing substrate 1 is screwed with a cross protection frame 52, the lower part of the polishing substrate 1 is provided with a receiving slot 53, and the cross protection frame 52 covers and protects the driving components. Slot 54, the bottom end of the auxiliary chute 54 is provided with a through slot 55, the through slot 55 is arranged through the bottom end of the polishing substrate 1, an auxiliary slider 56 slides inside the auxiliary chute 54, and a connecting hole 57 is opened at the top of the auxiliary slider 56 to support The bottom end of the side surface of the rod 12 is fixed with a connecting plate 58, and the connecting plate 58 and the connecting hole 57 are screwed with screws 59.

[0068] The working principle of the present invention and the use flow: ...

Embodiment 3

[0071] On the basis of Example 2, refer to Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a device for polishing the edges and corners of machine tool parts:

[0072] Two sets of first auxiliary vertical chutes 60 are symmetrically opened on the two opposite inner walls of the polishing groove 4 in the length direction with the first vertical chute 17 as a symmetrical object. Auxiliary vertical sliding block 61, two sets of second auxiliary vertical sliding grooves 62 are symmetrically opened on two opposite inner walls in the width direction of polishing rectangular groove 4 with the second vertical sliding groove 26 as a symmetrical object. A second auxiliary vertical sliding block 63 is slidably connected inside 62. The top and bottom ends of the first auxiliary vertical chute 60 are flush with the top and bottom ends of the first vertical chute 17 respectively. The second auxiliary vertical chute 62 The top and bottom ends are flush with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com