Floating type two-dimensional double-piston pump

A floating type, piston pump technology, applied in the field of hydraulic pumps and hydraulic motors, can solve the problems of rapid cylinder temperature rise, displacement limitation, and high processing accuracy requirements, and achieves the goal of eliminating flow pulsation, compensating processing errors, and overcoming processing errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

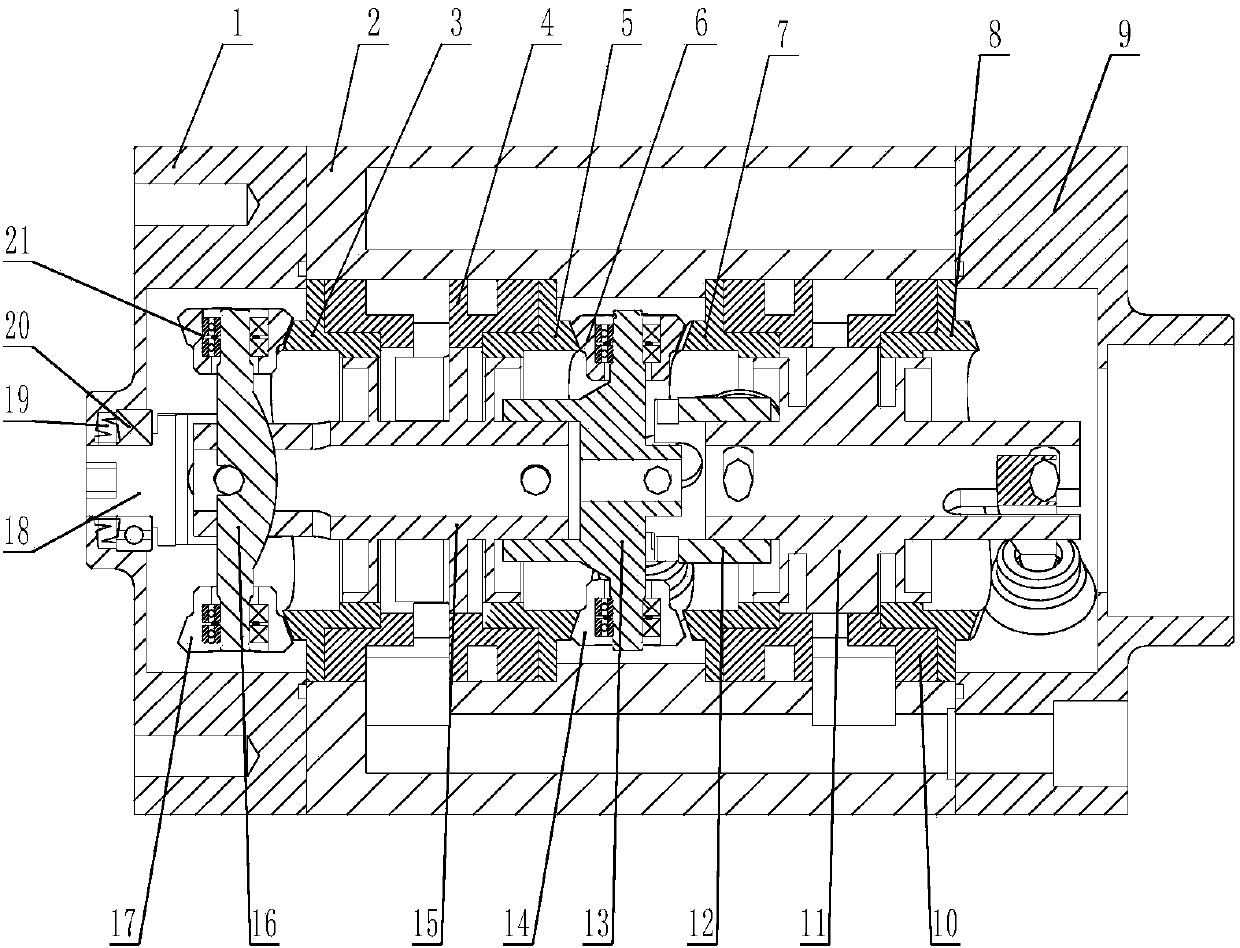

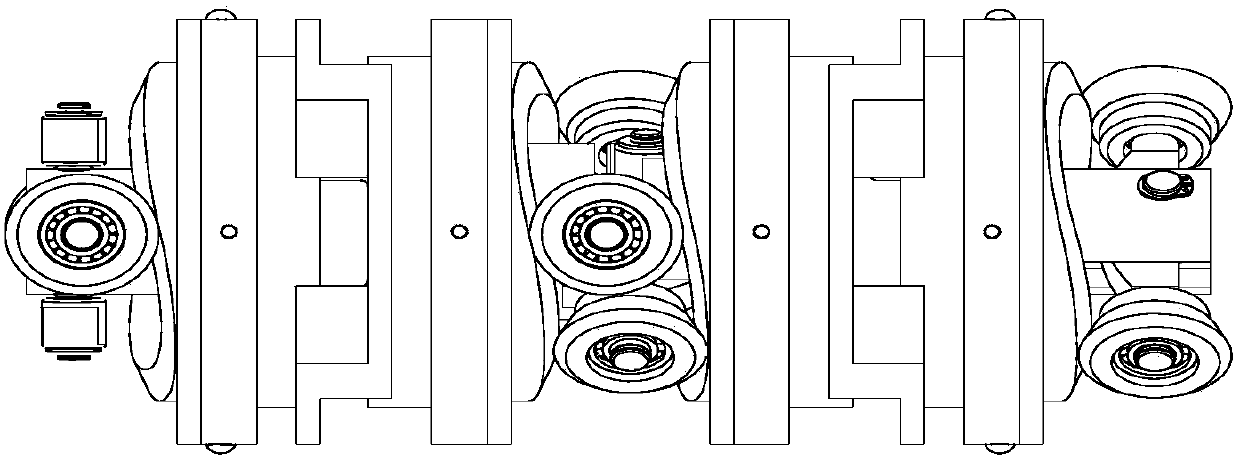

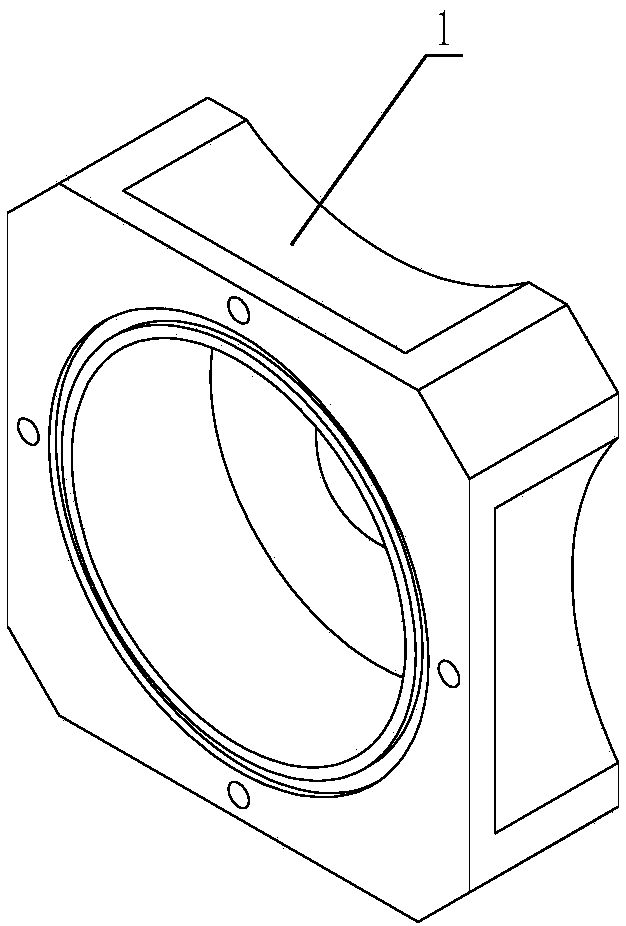

[0061] refer to Figures 1 to 22b , a floating two-dimensional double piston pump, including a pump body 2, an oil suction port and an oil discharge port are opened on the pump body 2, and a pump unit is arranged in the pump body 1, and it is characterized in that:

[0062] The pump unit includes two cylinders 4, 10 fixed in the pump body, and the two cylinders 4, 10 are arranged around the two cylinders, and pistons 15, 11 are arranged in the two cylinders, and the two pistons are linked with each other; the central axis of the cylinder is connected to the The central axis of the piston coincides, and both ends of the piston are equipped with moving components that drive the piston to move axially to cause the volume of the working chamber to change, and the moving directions of the moving components at both ends of the piston are opposite when the piston is driven to move;

[0063] The working chamber includes a left chamber and a right chamber respectively located at the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com