Automatic separating and discharging device for double-fork forgings

An automatic separation and unloading device technology, applied in the direction of stripping device, feeding device, positioning device, etc., can solve the problems of cumbersome operation, high punching efficiency, easy to scratch, etc., to ensure the separation effect and the sliding effect , to ensure the effect of rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

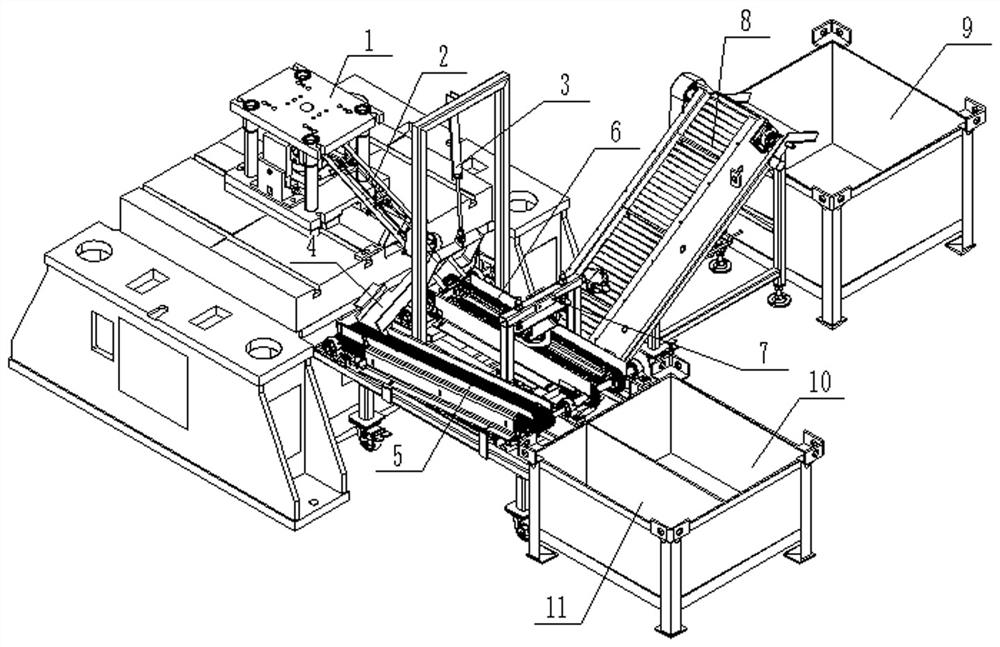

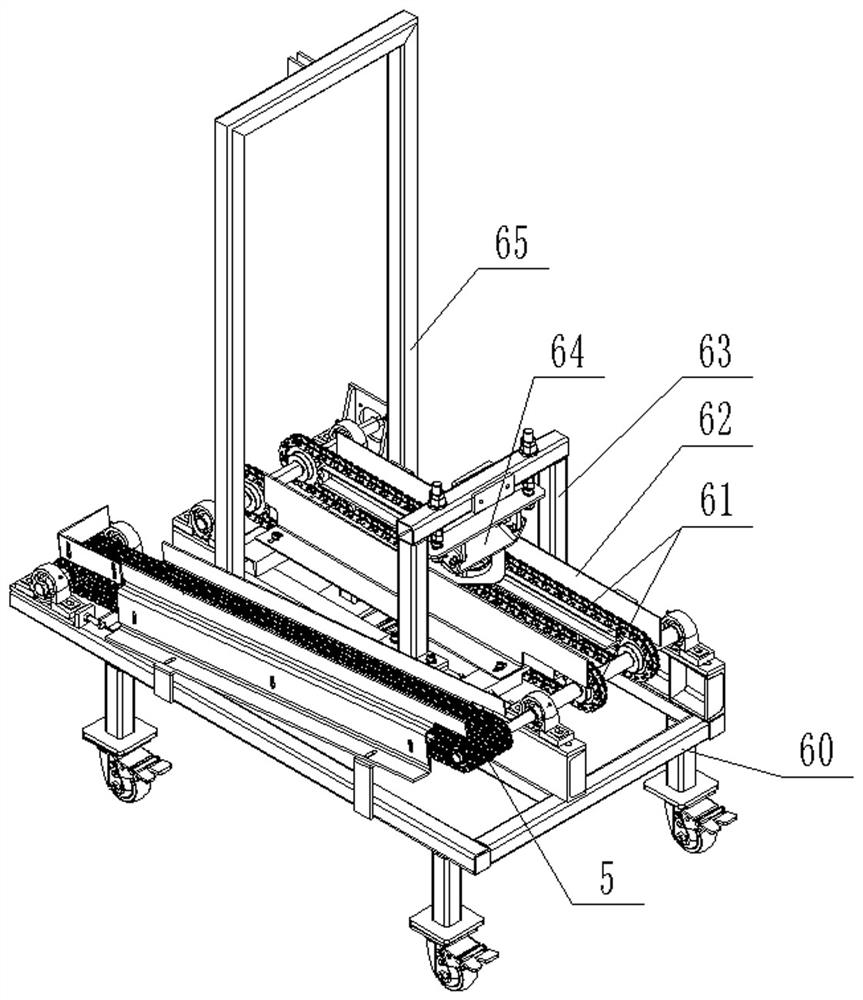

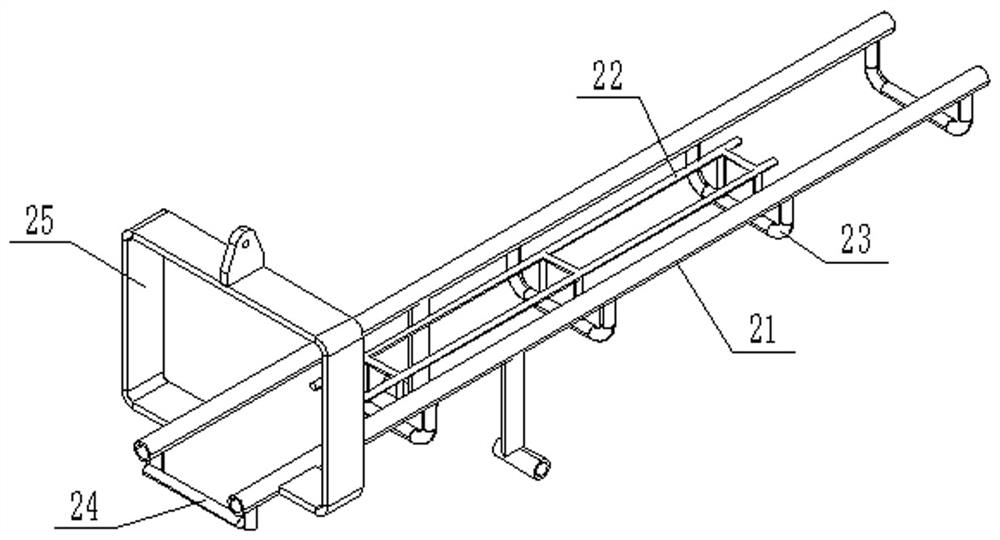

[0034] Such as Figure 1 to Figure 3 As shown, a double-fork automatic separation and unloading device for forgings is arranged on one side of the press 1, and specifically includes a skin-to-skin separation conveying slide 2, which slopes downward along the conveying direction, and the skin-to-skin separation The conveying chute 2 includes two slide bars 21, the bottoms of the two slide bars 21 are connected by a bottom connecting rod 23, the distance between the two slide bars 21 is greater than the distance between the outermost sides of the double forks 101 and less than the width of the flash 102, and the bottom of the two slide bars 21 is connected The distance between the rod 23 and the slide bar 21 is greater than the length of the double fork 101 at one end of the double fork forging. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com