Holding furnace of carbonization furnace

A technology for holding furnaces and carbonization furnaces, which is applied in carbonization furnaces and the petroleum industry. It can solve problems such as the inability to quickly raise the temperature and quickly cool down, and increase the cost of equipment production shutdown and maintenance. It is beneficial to production operations, short maintenance time, and temperature rise fast time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with examples.

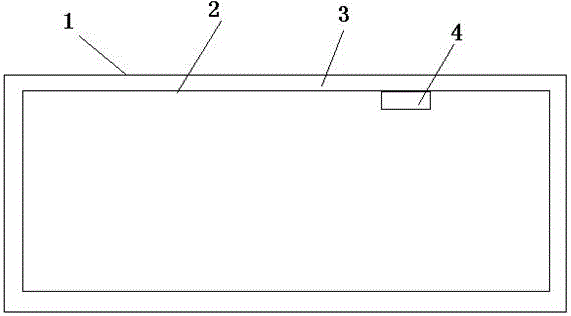

[0012] Such as figure 1 As shown, a carbonization furnace holding furnace body includes a furnace body. The furnace body is a double-layer furnace body structure, which is an outer layer furnace body 1 and an inner layer furnace body 2, and the outer layer furnace body 1 There is a hollow structure between the furnace body and the inner layer furnace body 2, and a fiber cotton layer 3 is arranged in the hollow structure, and a thermocouple 4 is arranged on the inner layer furnace body 2 of the furnace body body.

[0013] Preferably, the fiber cotton layer 3 is a ceramic fiber cotton layer.

[0014] Preferably, a furnace foot is provided on the furnace body.

[0015] The carbonization furnace in the present invention adopts a heat preservation furnace body, which can make the temperature raising time of the carbonization furnace fast. In addition, it can play a role of heat preservation dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com