Ultra-thin glass uniformly heating device

A uniform heating and ultra-thin glass technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low glass processing quality, untimely glass cooling, glass deformation, etc., and achieve easy heating, heat and Uniform cooling and easy cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

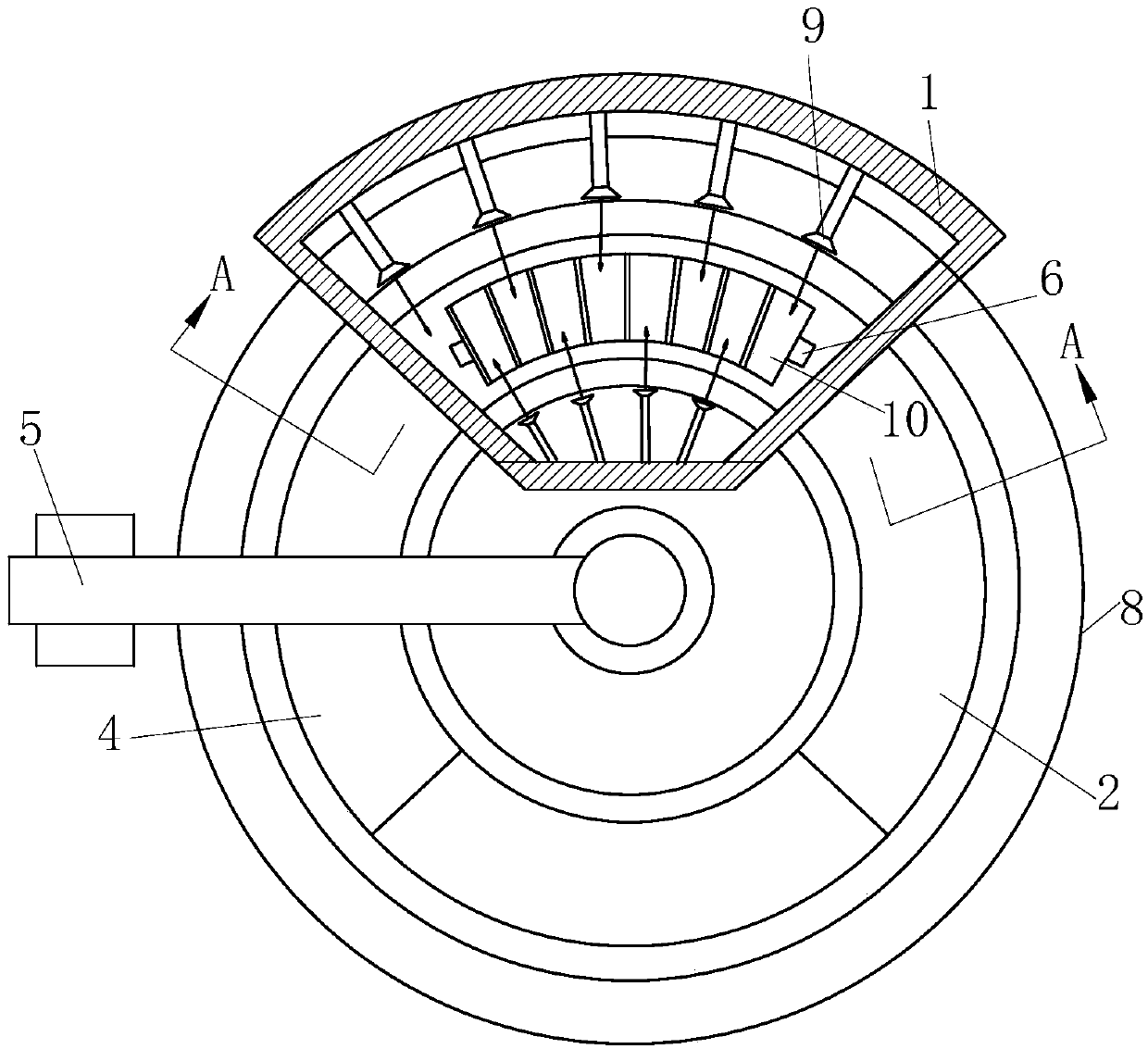

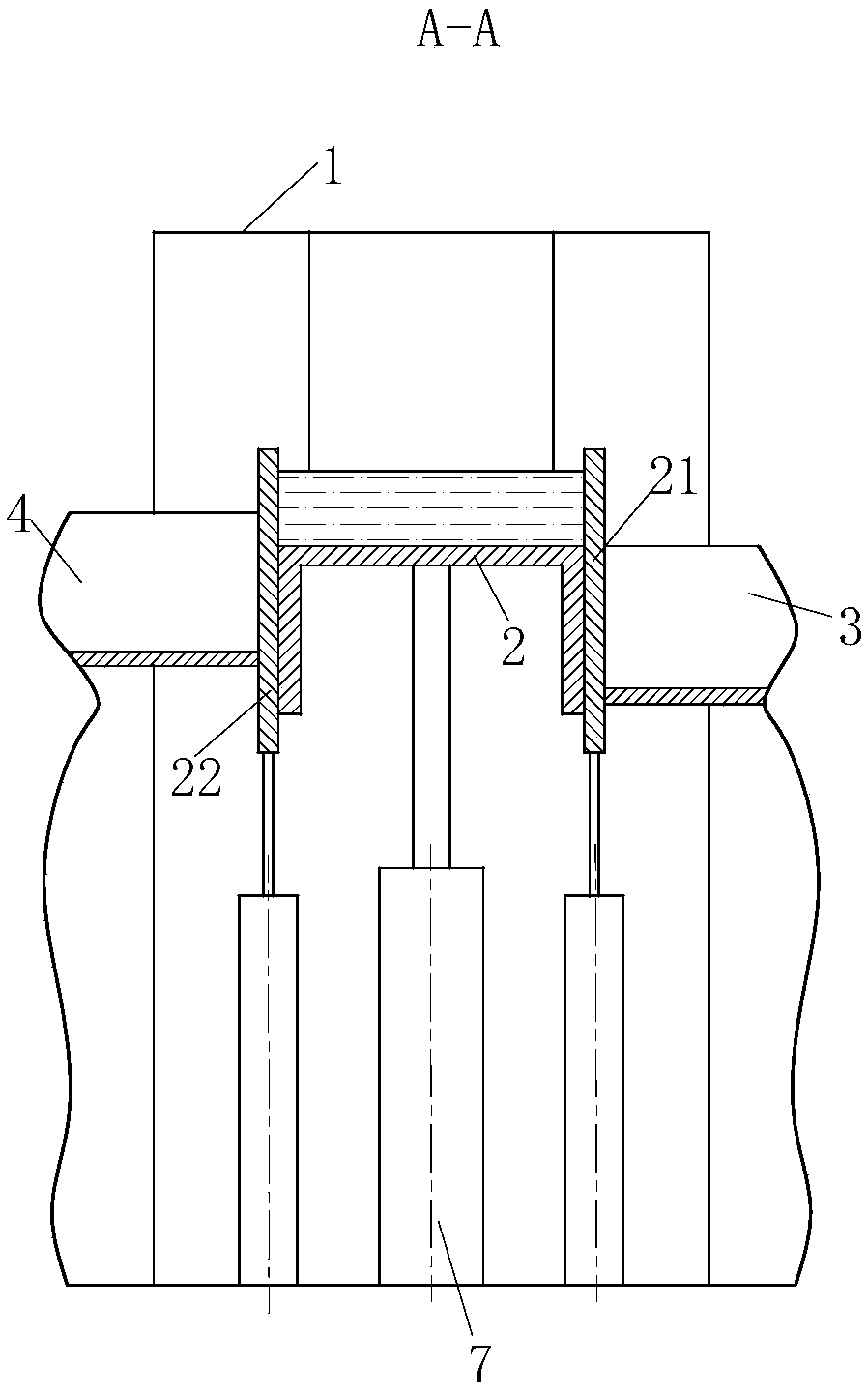

[0027] As an embodiment of the present invention, the hot gas nozzles 9 are arranged alternately on the front and rear inner walls of the heating furnace 1, and the hot gas ejected from the hot gas nozzles 9 is blown towards the middle of the two glasses. When starting, the hot air nozzles 9 on both sides spray hot air to both sides of the glass, and the hot air nozzles 9 at both ends of the same piece of glass are directed to the two sides of the glass respectively. , attracting the hot gas sprayed from the hot gas nozzle 9 on the other side of the glass, so that the hot gas forms an enveloping hot gas circulation on the glass, increases the heating speed of the glass, and improves the processing efficiency of the glass.

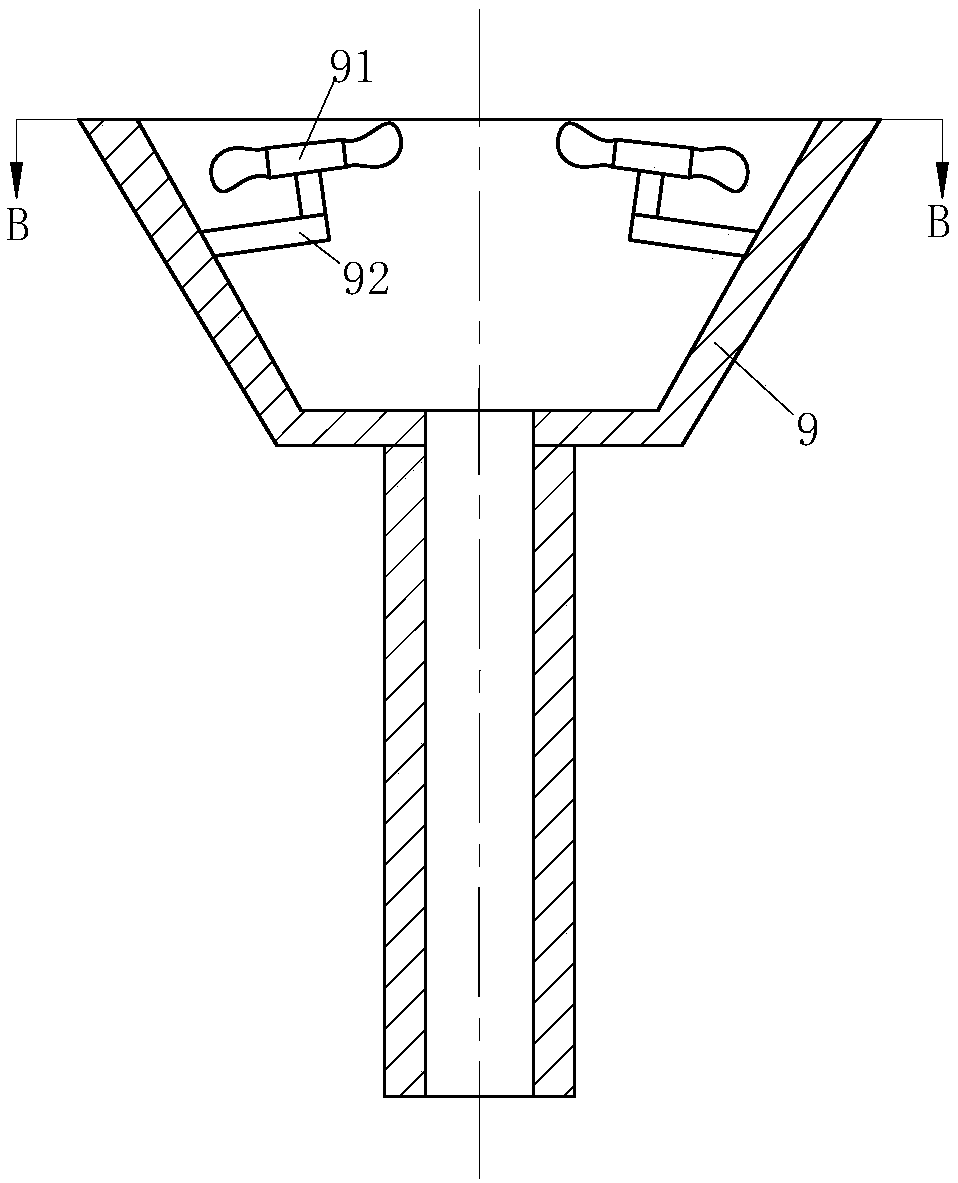

[0028] As an embodiment of the present invention, the outlet end of the hot air spray head 9 is provided with a fan 91; the number of the fans 91 is four, and the fans 91 are evenly distributed at the outlet end of the hot air spray head 9, and the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com