3V bunch iron tower and construction process thereof

A construction technology and technology of iron towers, applied in the direction of space arrangement/configuration of towers and cables, building types, etc., can solve problems such as large corridor occupation, increase line length, and increase project cost, so as to reduce construction difficulty, optimize structure, The effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

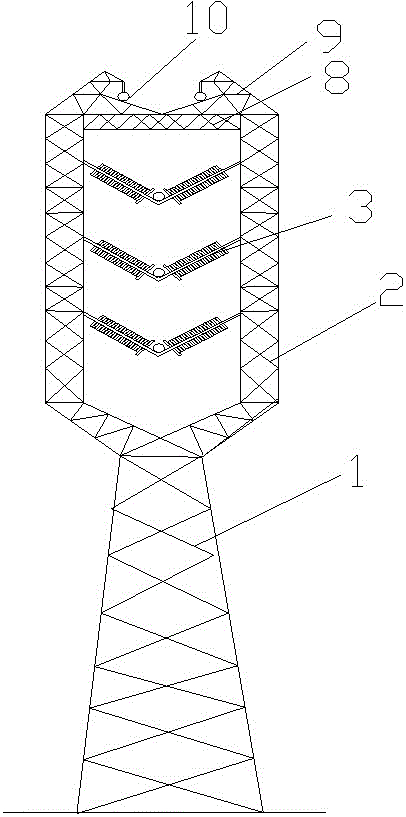

[0020] The 3V series iron tower of the present invention comprises a tower base 1 and a U-shaped fork 2 arranged on the tower base 1. In the U-shaped fork 2, three sets of V-shaped strings 3, namely upper, middle and lower, are arranged side by side at intervals. High-voltage cables 4 are arranged at intervals on the V-shaped string 3 .

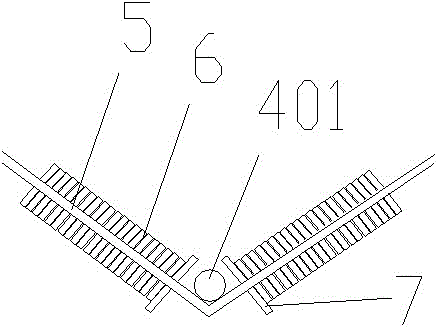

[0021] Further, in order to design rationally, prevent wires from deicing and jumping and limit cable galloping, the V-shaped string includes V-shaped non-conductive brackets 5, and a plurality of insulators 6 are connected in series on both sides of the V-shaped non-conductive brackets 5 , a high-voltage cable 401 passes through the bottom of the groove of the V-shaped non-conductive bracket.

[0022] Further, in order to prevent mutual interference and prevent wires from deicing and jumping, flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com