Closed sand mixing device and method

A sand mixing and sand conveying technology, applied in chemical instruments and methods, mixers, earthwork drilling, etc., can solve the problems of large water lock damage, small pore throats, low abundance, etc., to improve sand conveying speed, reduce Seal failure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

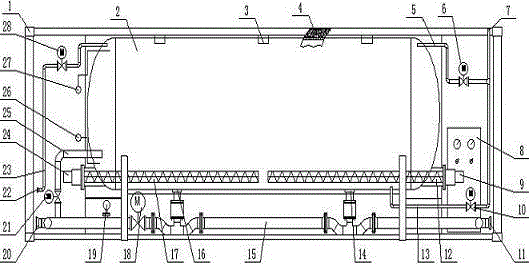

[0025] This embodiment provides a closed sand mixing device, including a frame 1, a tank body 2 arranged in the frame 1 and a main manifold 15 arranged below the tank body 2, the tank body 2 is a horizontal pressure tank, and the The top of the tank body 2 is provided with a gas phase channel, the top is provided with a plurality of sand filling ports 3, the bottom is provided with a liquid phase channel, and the bottom is provided with a plurality of sand outlets. Sand device, the sand outlet is in one-to-one correspondence with the sand delivery device, one end of the sand outlet is connected to the outlet of the sand delivery device, and the other end is connected to the main manifold 15, and the sand delivery device is connected to an electric control cabinet 8. The upper part of the tank body 2 is provided with a gas phase discharge manifold 5, and the gas phase discharge manifold 5 is provided with a gas phase discharge valve 6.

[0026] The airtight sand mixing device i...

Embodiment 2

[0028] On the basis of Embodiment 1, this embodiment provides a closed sand mixing device. The liquid inlet 20 of the main manifold 15 is sequentially provided with a liquid replenishing manifold 25, a flow meter 19 and a differential pressure valve 18 along the direction of liquid flow. , the liquid replenishment manifold 25 communicates with the middle of the tank body 2, and the liquid replenishment manifold 25 is provided with a liquid replenishment valve 21, and the flow meter 19 and the liquid replenishment manifold 25 are both electrically connected to the electric control cabinet 8.

[0029] In this embodiment, the sand conveying device is a sand conveying screw, and the sand conveying screw includes a screw shaft and a motor. The optical axis between the helical part and the helical part in the opposite direction is aligned with the sand outlet, and the motor is electrically connected with the electric control cabinet 8 .

[0030] The sand conveying screw is driven by...

Embodiment 3

[0032] On the basis of Embodiment 2, this embodiment provides a closed sand mixing device, the upper part of the tank body 2 is provided with a nitrogen booster manifold 23, and the nitrogen booster manifold 23 is provided with a nitrogen booster valve 28. The bottom of the tank body 2 is provided with a liquid-phase discharge manifold 13, and the liquid-phase discharge manifold 13 is provided with a liquid-phase discharge valve 10, and the nitrogen booster valve 28 and the liquid-phase discharge valve 10 are all connected Cabinet 8 is electrically connected.

[0033] Among them, the nitrogen pressurization manifold 23 can realize liquid level control during the construction process, replace the liquid in the tank body 2 after the construction is completed, and discharge all the liquid to prevent dry ice from forming in the tank body 2 .

[0034] In this embodiment, the gas phase discharge manifold 5 , the nitrogen pressurization manifold 23 , the liquid phase discharge manifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com