Supporting structure for six-pilot-holes large-section metro station undercrossing existing line

A technology for subway stations and supporting structures, applied in underground chambers, shaft linings, tunnel linings, etc., can solve the problems of low pile formation efficiency of large-diameter pile foundations, poor overall use function of stations, and large deformation and settlement of existing lines. Achieve the effect of improving the overall use function and riding experience, fast construction speed, and overcoming the difficulty of hole forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

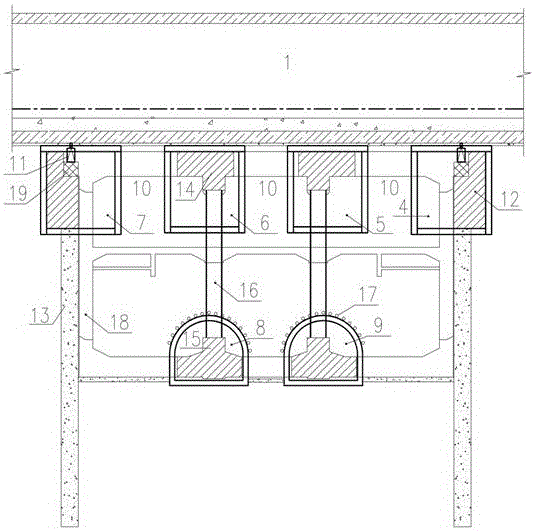

[0035] The present invention will be further explained below in conjunction with the drawings.

[0036] See as Figure 1-Figure 6 as well as Figure 7-1 to Figure 7-12 As shown, the technical scheme adopted in this specific embodiment is: it includes working well 2, advanced soil reinforcement 3, No. 1 pilot hole 4, No. 2 pilot hole 5, No. 3 pilot hole 6, No. 4 pilot hole 7, 5 No. 8 pilot hole, No. 6 pilot hole 9, the soil between the upper pilot hole 10, the jack 11, the pile crown beam 12, the bored pile 13, the top longitudinal beam and part of the roof 14, the bottom longitudinal beam and part of the bottom plate 15 , Steel pipe column 16, advance conduit 17, underpass station main structure 18, jack temporary support mechanism 19, steel plate 20, pilot tunnel initial support 21, crown beam top embedded grouting conduit 22; two working wells 2 are arranged symmetrically On the left and right sides of the existing line 1, and between the two working wells 2, there is advanced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com