A kind of treatment method of papermaking wastewater

A treatment method and technology for papermaking wastewater, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing infrastructure investment and operating costs, stable operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

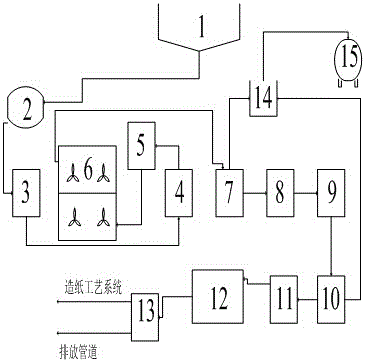

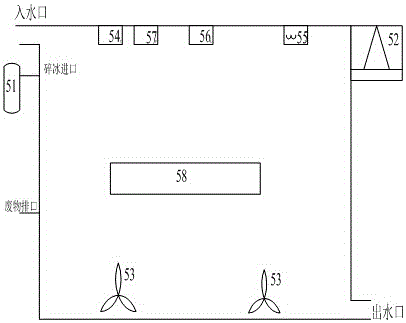

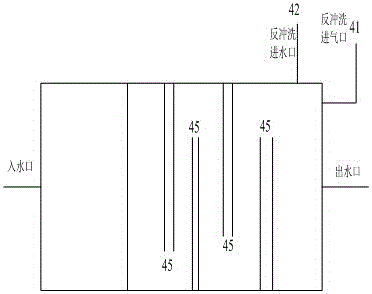

[0020] like figure 1 As shown, a papermaking wastewater treatment method, the method is implemented through a wastewater treatment system, the system includes a buffer pool 1, an inclined screen 2, a grit chamber 3, a high-speed filter pool 4, a crushed ice condensation pool 5, and a rotary adsorption pool 6. Aeration tank 7, regulating tank 8, biochemical reaction tank 9, secondary sedimentation tank 10, retention tank 11, artificial fish pond 2, water storage tank 13, mud storage tank 14, belt filter press 15. The waste water from the paper mill enters the water inlet of the buffer tank 1 through the pipeline, the water outlet of the buffer tank 1 is connected to the water inlet of the inclined filter 2 through the pipeline, and the water outlet of the inclined filter 2 is connected to the water inlet of the grit chamber 3 through the pipeline, and the sedimentation The water outlet of the sand tank 3 is connected to the water inlet of the high-speed filter tank 4 through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com