High-efficiency electric steering pump

An electric steering and high-efficiency technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of high transmission noise and low transmission efficiency of steering pumps, and achieve the effect of improving transmission efficiency and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

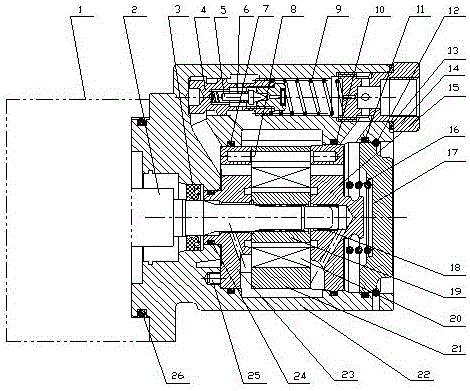

[0010] The structure of the high-efficiency electric steering pump of the present invention is as follows: figure 1 As shown, the shaft 2 and the motor assembly 1 have a coaxial structure, and the motor assembly 1 is assembled at one end of the same shaft 2, and all the parts of the steering pump are put into the integral pump body 22 at the other end, and then closed with the pump cover 17, the pump The steel wire retaining ring 12 is fixed between the cover 17 and the pump body 22 . The pump body 22 is provided with an oil inlet side plate 23 and an oil outlet side plate 15, the shaft 2 is installed through the center of the oil inlet side plate 23 and the oil outlet side plate 15, the oil inlet side plate 23, the stator 21 and the oil outlet side plate 15 The positioning pin 8 is connected through the pump body 22 to limit the degree of freedom of rotation. A spring 16 is installed between the oil outlet side plate 15 and the pump cover 17, and the spring 16 presses on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com