Air spring with continuously adjustable stiffness and air spring system with continuously adjustable stiffness

An air spring and stiffness technology, applied in the field of auto parts, can solve the problems of inconvenient layout, large space occupied by the air spring, affecting the design work of the whole vehicle, etc., and achieve the effect of simple structure, stable contact, and easy design and implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

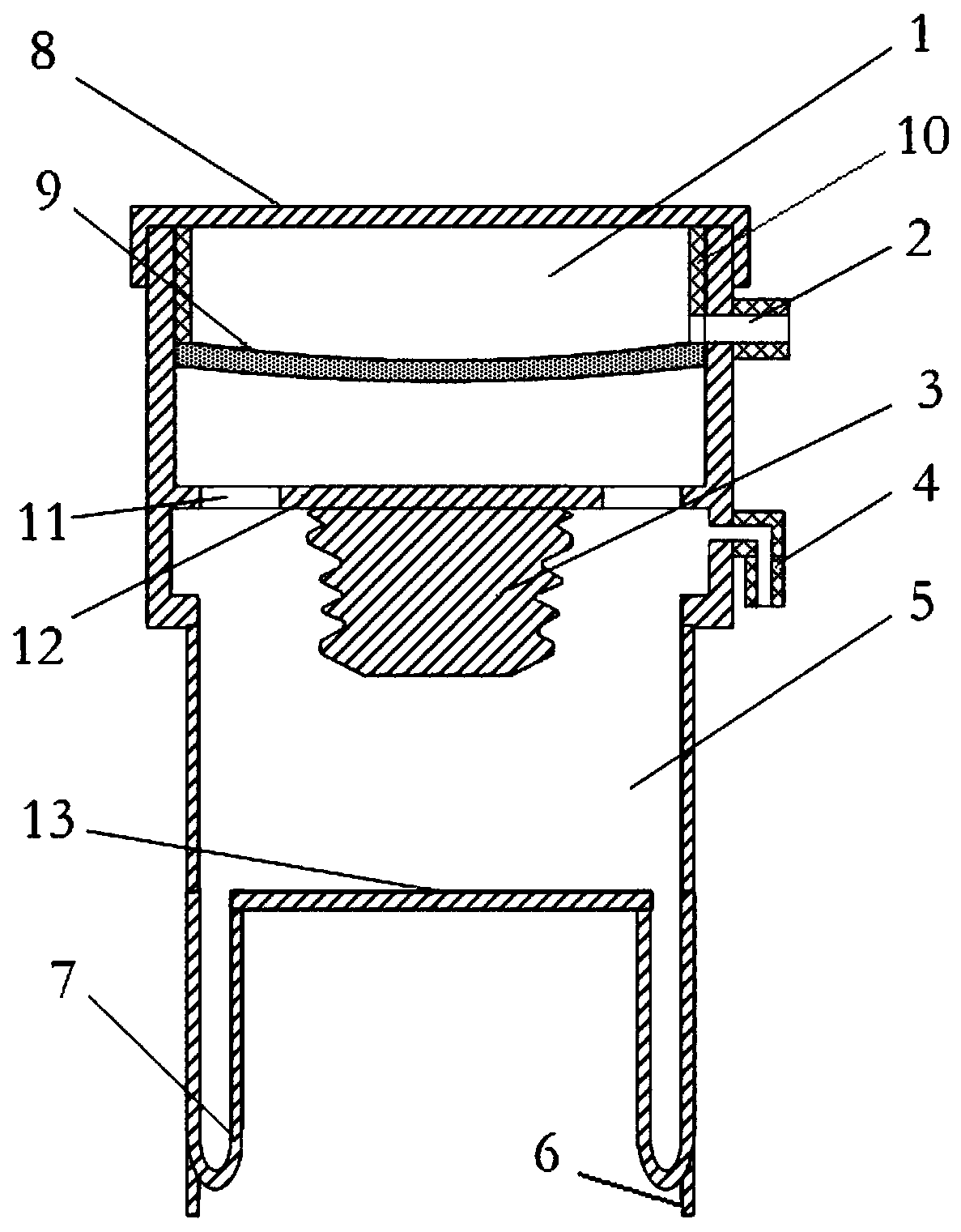

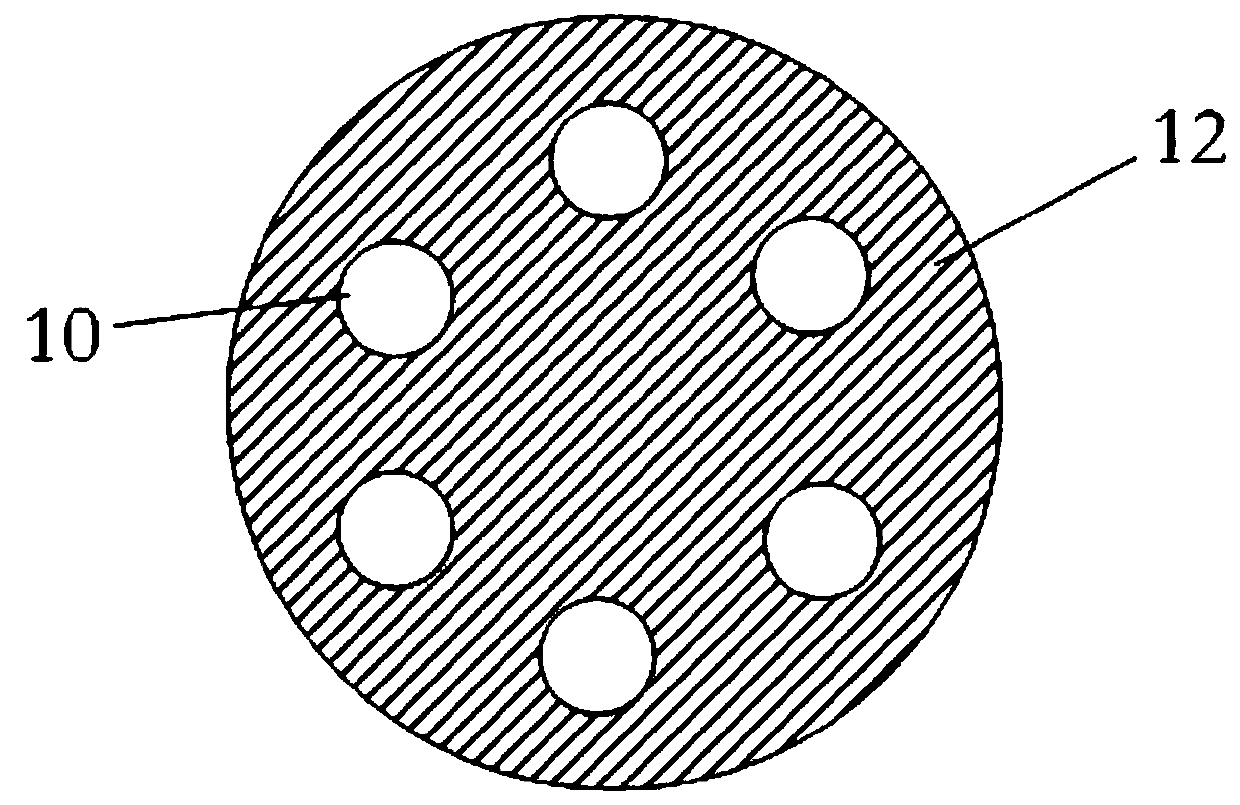

[0033] This embodiment relates to an air spring with continuously adjustable stiffness, such as figure 1 As shown in , it includes a tubular casing 6, one end of the casing 6 is closed by a sealing cover 8, the other end of the casing 6 is connected with a base 13 via an air bag 7, and a connection with the casing 6 is also provided on the casing 6. The air port 4 connected internally. In this embodiment, an elastic diaphragm 9 is also provided in the housing 6, and the elastic diaphragm 9 separates the housing 6 into a first chamber 5 and a second chamber 1 located on both sides of the elastic diaphragm 9, and the aforementioned air port 4 is connected with The first chamber 5 communicates, and an oil port 2 communicating with the second chamber 1 is also provided on the housing 6 .

[0034] In this embodiment, the elastic diaphragm 9 can be made of rubber, and vulcanized and connected to the inner wall of the housing 6. In order to ensure the stability of the elastic diaphr...

Embodiment 2

[0039] This embodiment relates to an air spring system with continuously adjustable stiffness, which includes the air spring with continuously adjustable stiffness as described in Embodiment 1, and also includes an air source connected to the air port on the air spring, and connected to the oil port. A connected hydraulic source, and a controller that controls the operation of the above-mentioned air source and hydraulic source to fill and deflate the first chamber or inject and discharge oil into the second chamber. The controller can be the ECU of the car, the air source can be an air compressor or an air storage bottle installed on the car, and the hydraulic pressure source can also be a hydraulic pump or a hydraulic cylinder arranged on the car.

[0040]When the air spring system with continuously adjustable stiffness is in use, the controller can control the amount of oil injected from the hydraulic source to the second chamber according to the settings of different operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com