Driving intention identifying method suitable for multi-performance comprehensive optimization of gear shift schedule

A technology for shifting rules and identification methods, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficulty in meeting individual requirements for automatic shifting, and achieve simple classification and automatic shifting Block the effect of personalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, in conjunction with the application of the driving intention recognition method in the multi-performance comprehensive optimization of a certain 5-speed electronically controlled mechanical automatic transmission (AMT) shift schedule, the present invention will be further described.

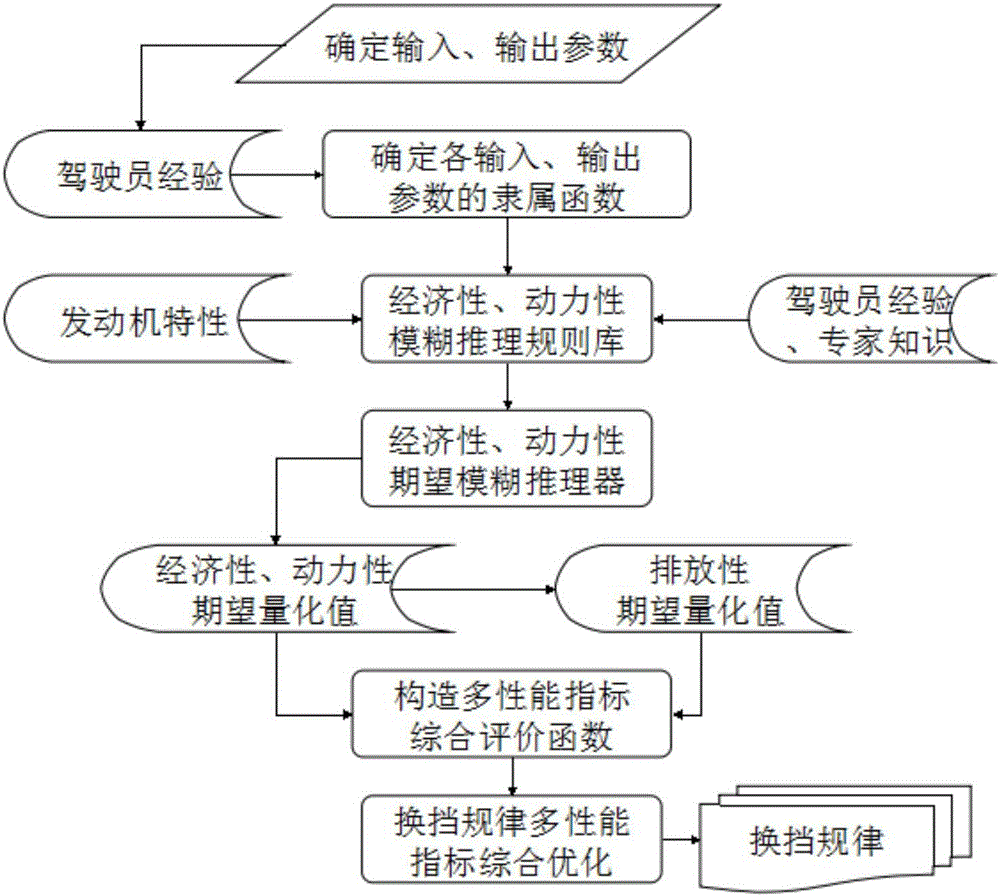

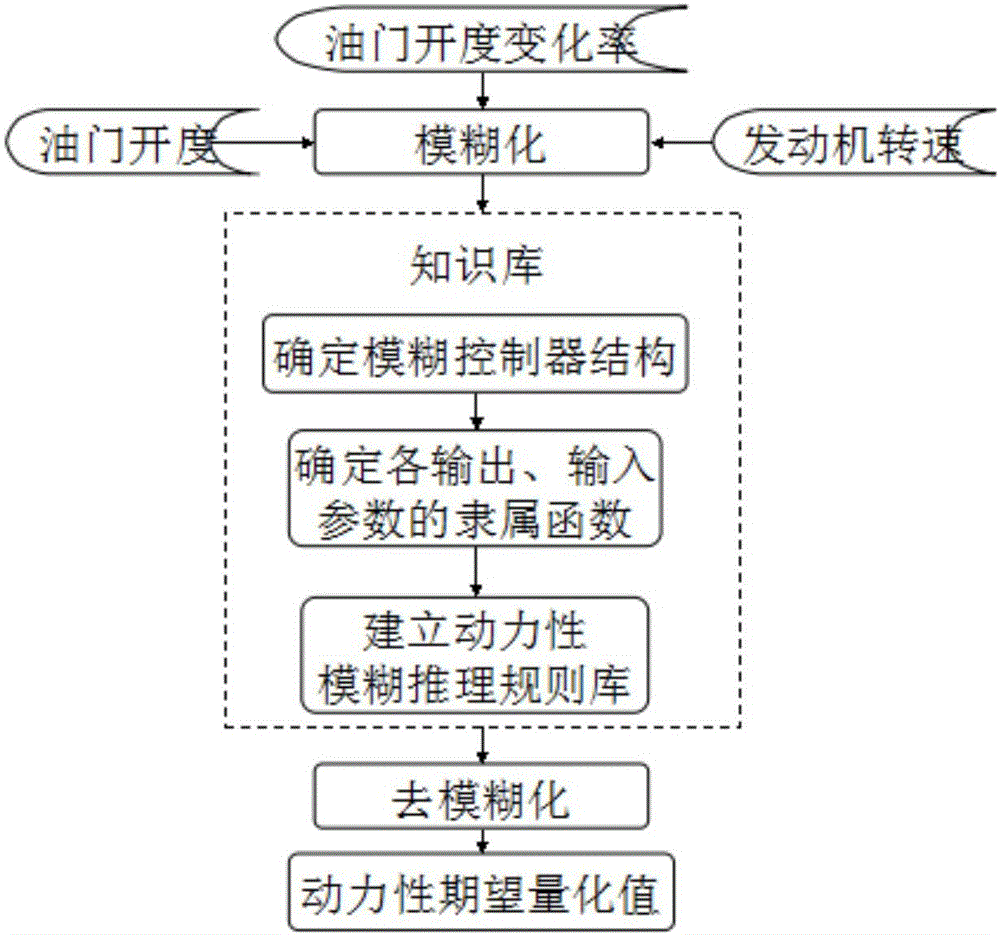

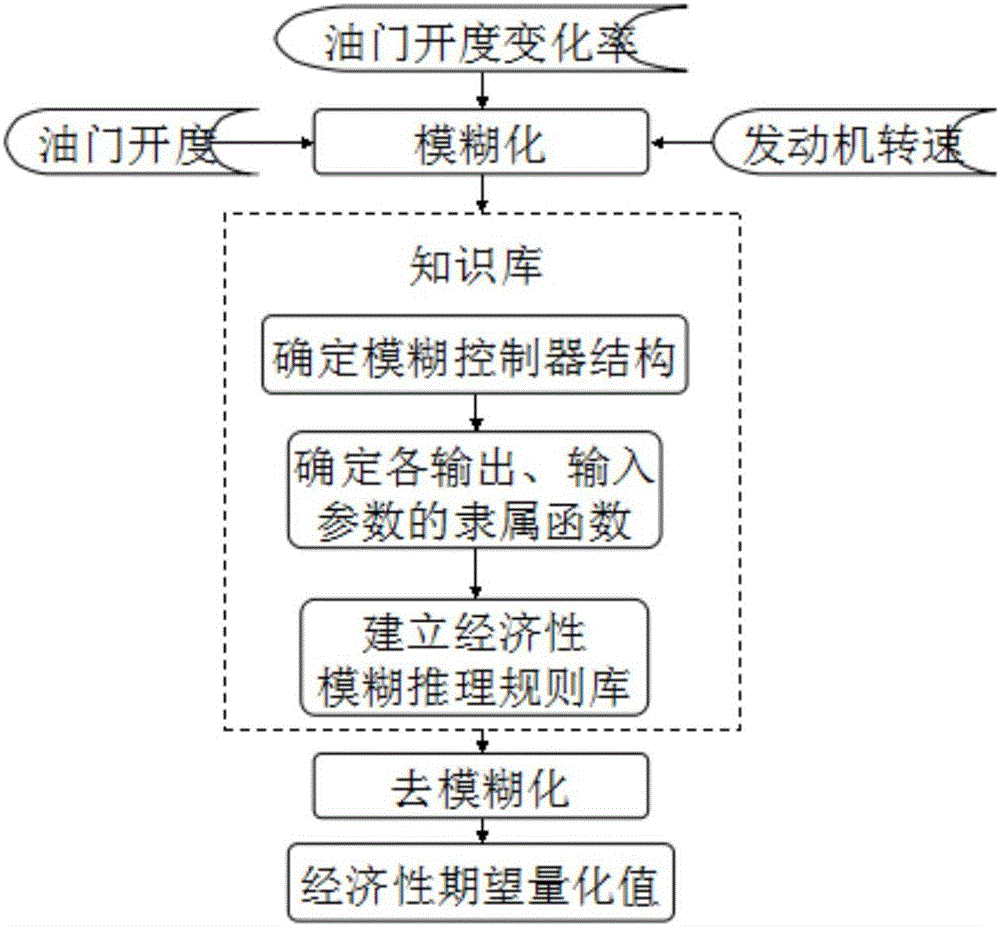

[0054] figure 1 It is the general scheme of the driving intention recognition method for the multi-performance index comprehensive optimization of the shift schedule of the stepped automatic transmission. The fuzzy reasoner is used to quantify the driver's power expectation and economic expectation, and the driver's dynamic performance Emissions performance expectations are determined based on quantitative expectations and economical expectations. Aiming at the construction of dynamic expectation and economic expectation fuzzy reasoner, respectively determine the input parameters of fuzzy reasoner and the output parameters of fuzzy reasoner, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com