Valve structure provided with coded lock

A combination lock and valve technology, applied in the direction of valve lift, valve detail, valve device, etc., can solve the problems of poor safety and troublesome operation of limited filling, and achieve the effect of high safety and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

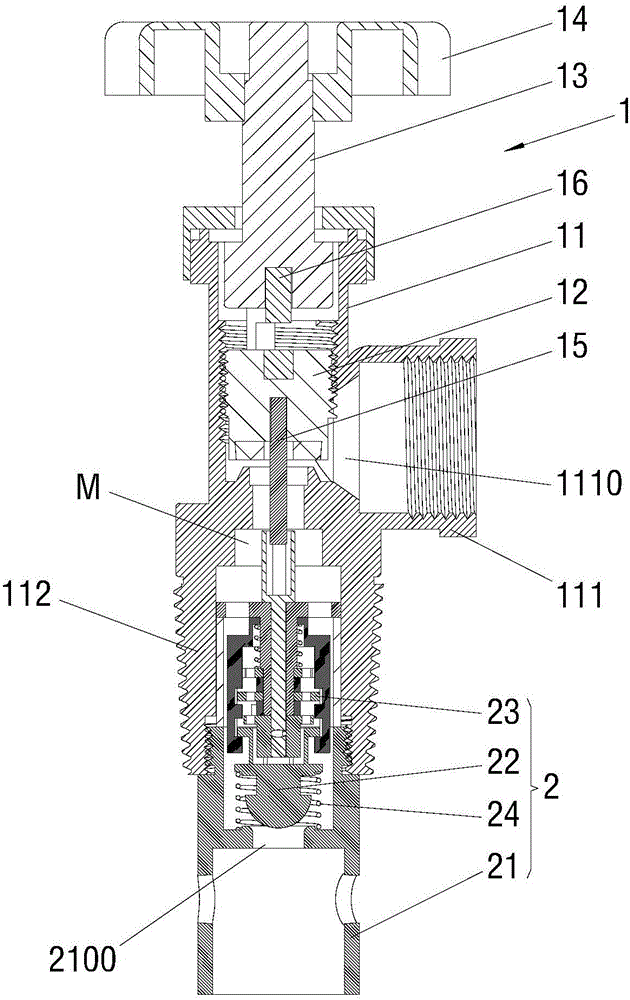

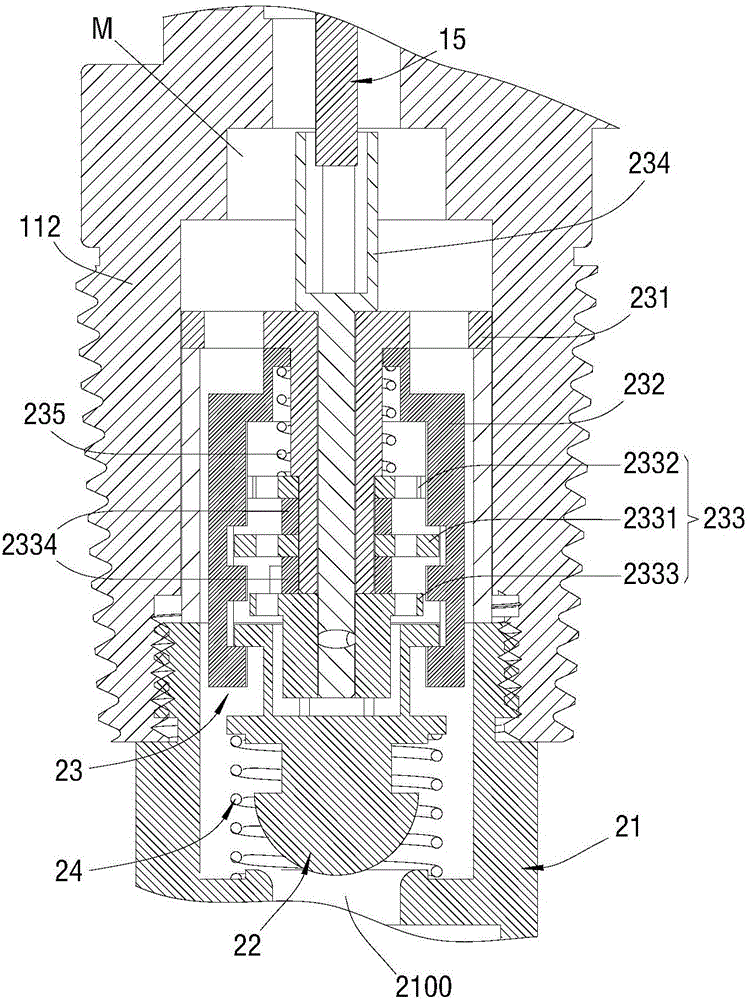

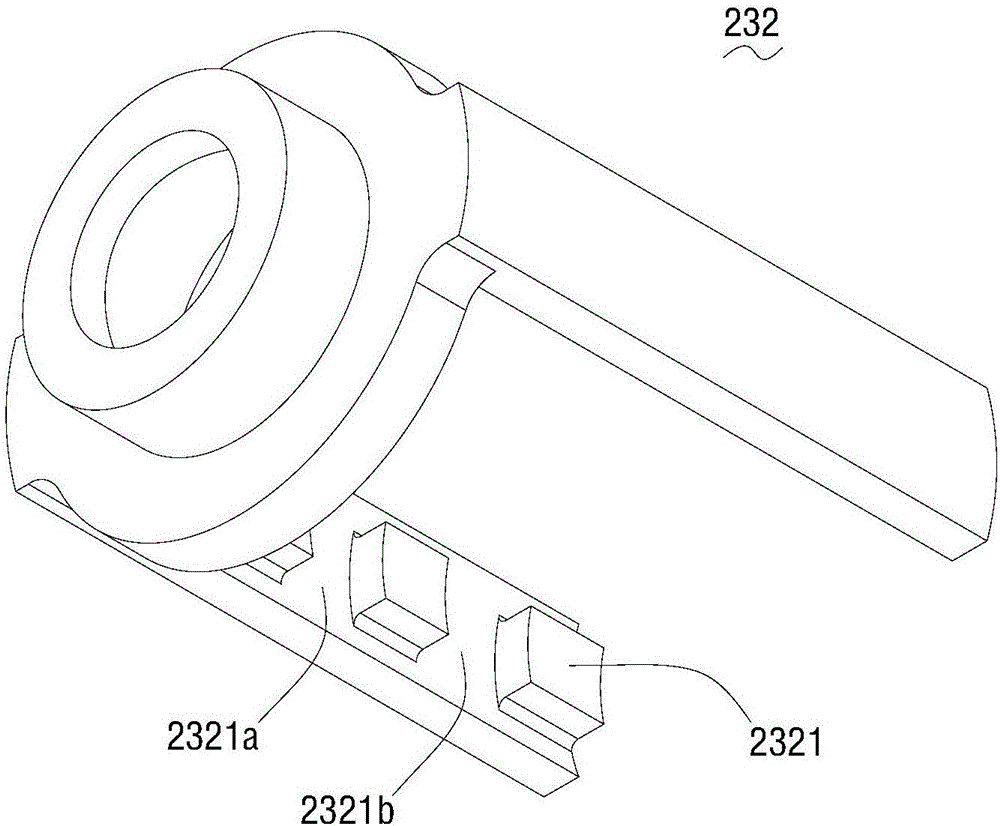

[0044] Such as Figure 1 to Figure 11 As shown, the bottom end of the valve body 11 has an extension 112 that can be connected to a gas cylinder (liquefied gas cylinder, oxygen cylinder, etc.), the extension 112 communicates with the air passage M, and the combination lock assembly 2 is arranged on the extension. Section 112. Specifically, one end of the above-mentioned fixed cylinder 21 extends into the extension portion 112 to form a fixed connection and communication. At the same time, the blocking body 22 and the combination lock 23 are arranged in the cavity formed by the connection between the fixed cylinder 21 and the extension portion 112. Here, the combination lock 23 is specifically located in the extension part 112, the blocking body 22 is located in the fixed cylinder 21, and the lower end of the fixed cylinder 21 can extend into the gas cylinder; Under the state that coded lock 23 is self-locked and blocking body 22 breaks away from this coded lock 23 or under th...

Embodiment 2

[0062] Such as Figure 12 with Figure 13 As shown, the outer wall of the valve body 11 has a side joint 111 that can be connected to an air gun, and the inner end of the side joint 111 has an air inlet and outlet 1110 that communicates with the air passage M and can be sealed and matched with the blocking body 22 . One end of the fixed cylinder 21 extends into the side connection portion 111 to form a fixed connection and communication, and the combination lock 23 is arranged between the fixed cylinder 21 and the side connection portion 111. Here, the fixed cylinder 21 has an inner cavity 210, and the combination lock 23 is specifically set in the lumen 210 . In this embodiment, when the combination lock 23 is self-locking and the blocking body 22 is out of the combination lock 23 or in the state where the combination lock 23 is unlocked and the blocking body 22 is locked, the blocking body 22 can be pushed by the filling fluid. Block the air inlet and outlet 1110 to block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com