Control method and heat pump unit for controlling operation of compressor

A control method and compressor technology, applied in the field of heat pumps, can solve problems such as not being able to guarantee the life cycle of the compressor, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be described in detail below by means of exemplary embodiments with reference to the drawings. The following detailed description of the present invention is for the purpose of illustration only, and in no way limits the present invention and its application or use.

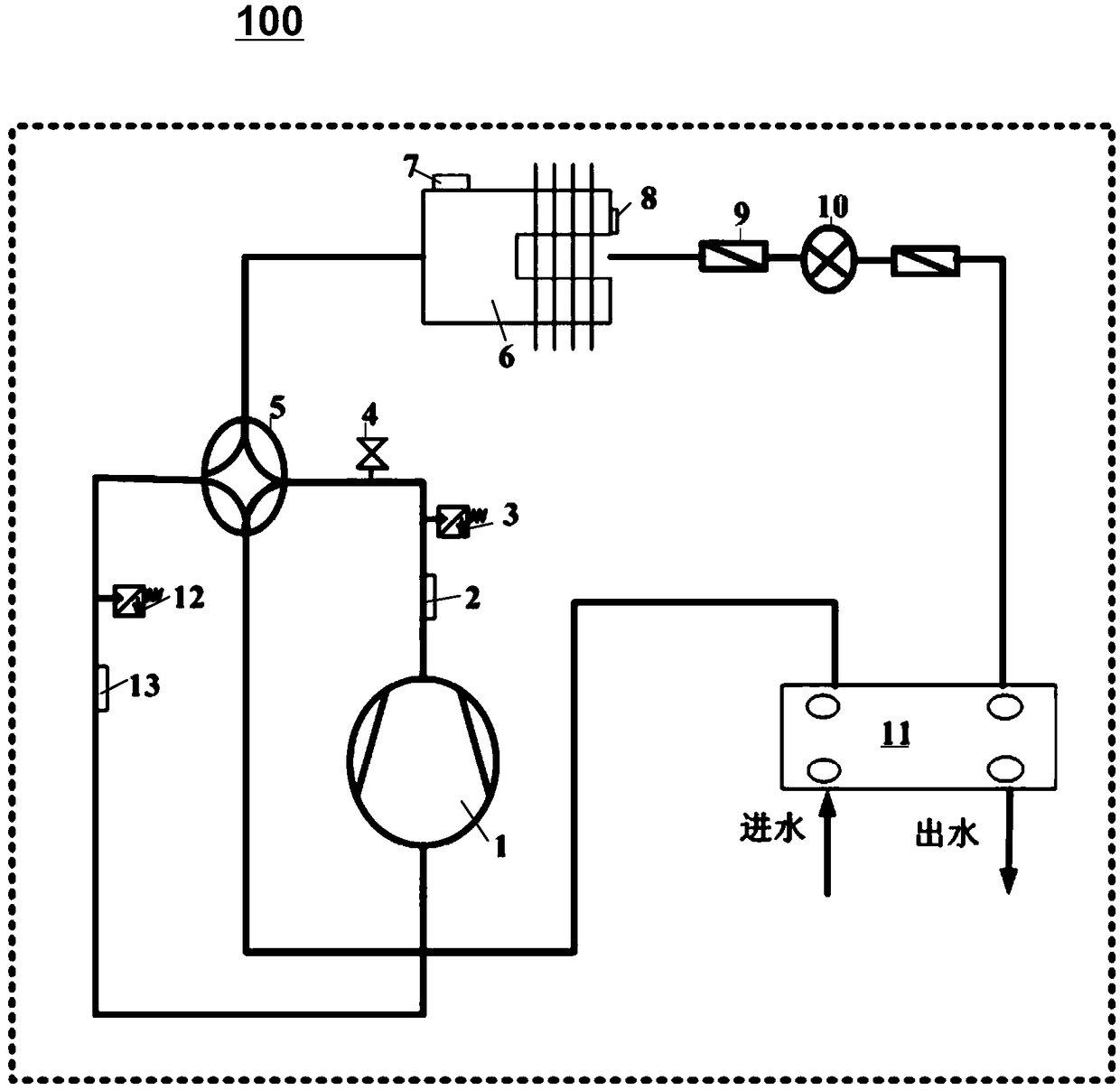

[0021] refer to figure 1 ( figure 1 To show a structural block diagram of the heat pump unit according to the present invention), the heat pump unit 100 according to the present invention includes a compressor 1 and a control device (not shown). In the illustrated example, the heat pump unit 100 may also include: exhaust temperature sensor 2, high pressure sensor (exhaust pressure sensor) 3, high pressure switch 4, four-way valve 5, fin heat exchanger 6, ambient temperature sensor Package 7, defrosting temperature sensing package 8, filter 9, electronic expansion valve 10, plate heat exchanger 11, low pressure sensor (suction pressure sensor) 12 and suction temperature sensing packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com