Tool for detecting jump of parts of shaft type

A technology for detecting tooling and shaft parts, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problems of inability to detect the relative runout of inner and outer diameters, deflectors, and increase the cumulative error of parts, so as to improve the detection efficiency. and detection accuracy, reduce detection damage, and reduce the effect of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

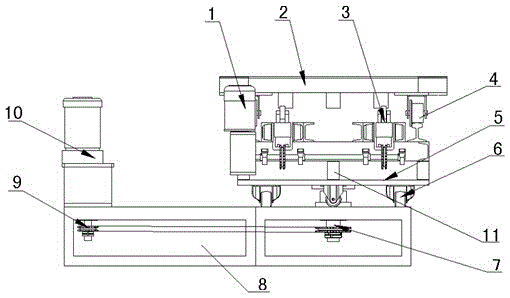

[0009] Depend on figure 1 It is known that a detection tool for the runout of shaft parts consists of a base 1, a support plate 2, a roller 3, a spacer 4, a mandrel 5, a locking block 6, a pull rod 7, an adjusting bolt 8, an adjusting nut 9, a hand Composed of 10, locking shaft 11 and threaded pin 12; according to the detection requirements of the parts, different numbers of support plates and roller groups are installed on the base, and the detection requirements of different parts are realized by adjusting the positions of the support plates and roller groups. The support plate is arranged on the base table with positioning grooves, and is fixed on the base through locking blocks, pull rods and locking shafts. There are two or more sets of support plates and rollers, all of which are arranged on the base through positioning slots and locked by locking mechanisms. The locking mechanism obtains sufficient locking force by turning the handle.

[0010] When working, first rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com