A test method for microscopic deformation of materials

A test method and material microscopic technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as single measurement function, and achieve the effect of solving relatively single measurement function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

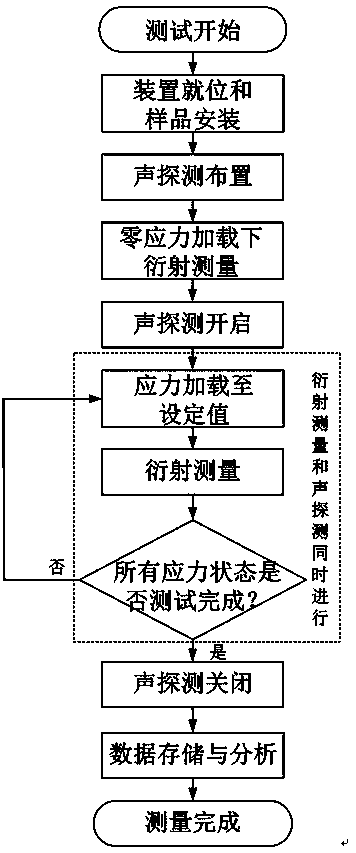

[0030] Such as image 3 Shown, the concrete steps of the testing method of material microscopic deformation of the present invention are as follows:

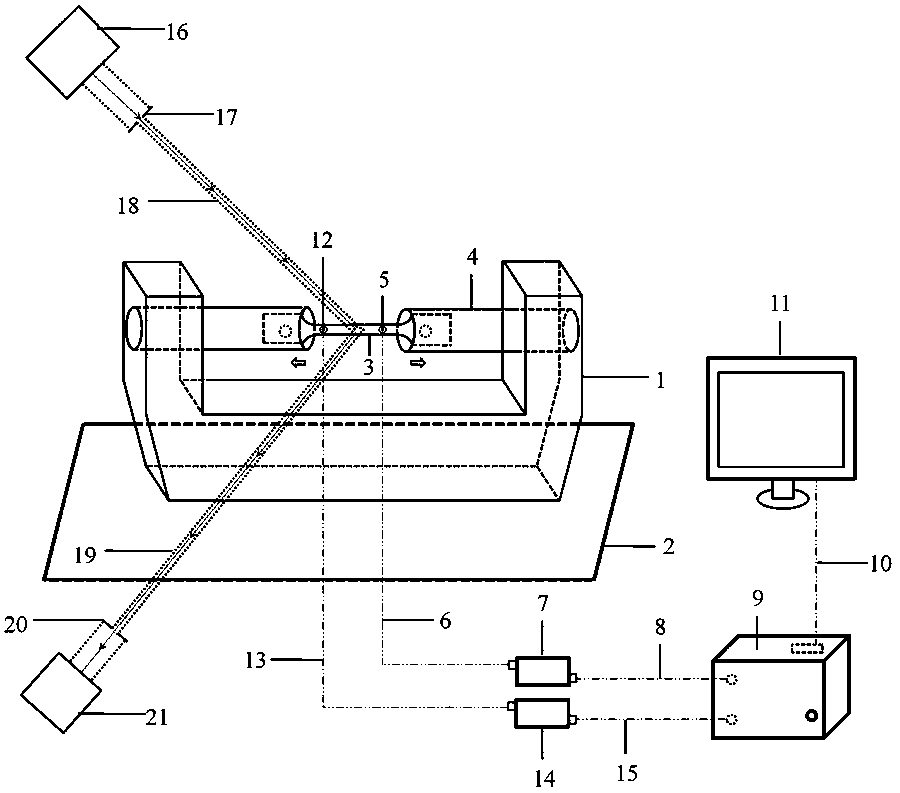

[0031] a. Symmetrical diffraction experiment layout

[0032] Place the stress loading device 1 on the load-bearing platform 2 of the diffraction experimental device, ensuring that the central axes of the two coincide. Then, the ray source 16 and the detector 21 are respectively arranged on both sides of the stress loading device 1 to form a basic geometric layout of the diffraction experiment in a symmetrical distribution. At the same time, the entrance aperture 17 and the exit aperture 20 are respectively placed at the front ends of the radiation source 16 and the detector 21 , and arranged close to the stress loading device 1 .

[0033] b. Two-channel acoustic detection arrangement

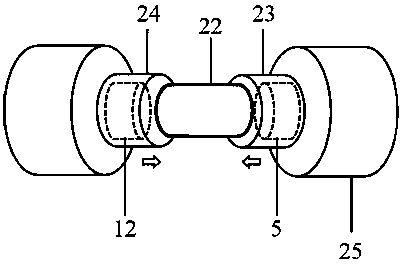

[0034] The sample 3 is installed on the stress loading device 1 through the clamp 4, and at the same time, the sample 3 is stretched to a pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com