A vehicle electronic device

An in-vehicle electronic, integrated technology, applied in the direction of elastic/clamping device, circuit arrangement on the support structure, etc., can solve the problems of affecting the installation stability, the influence of the electrostatic output of grounded parts, and increasing the difficulty of assembly, and achieve easy assembly and disassembly. , stable installation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

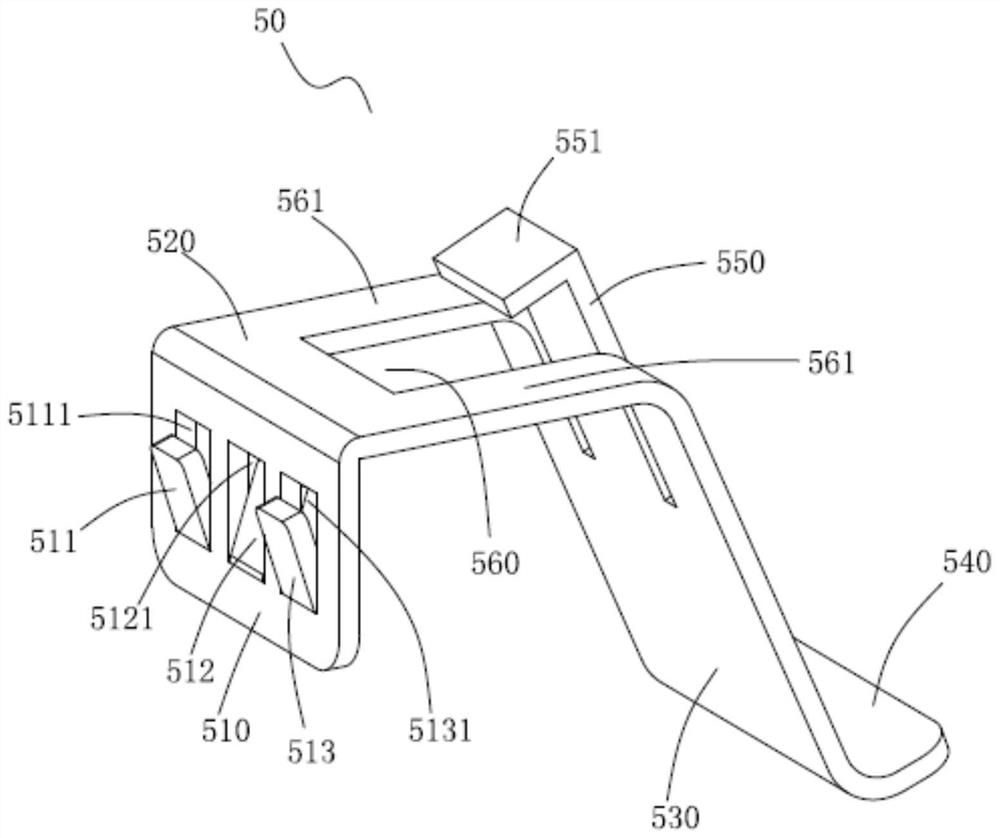

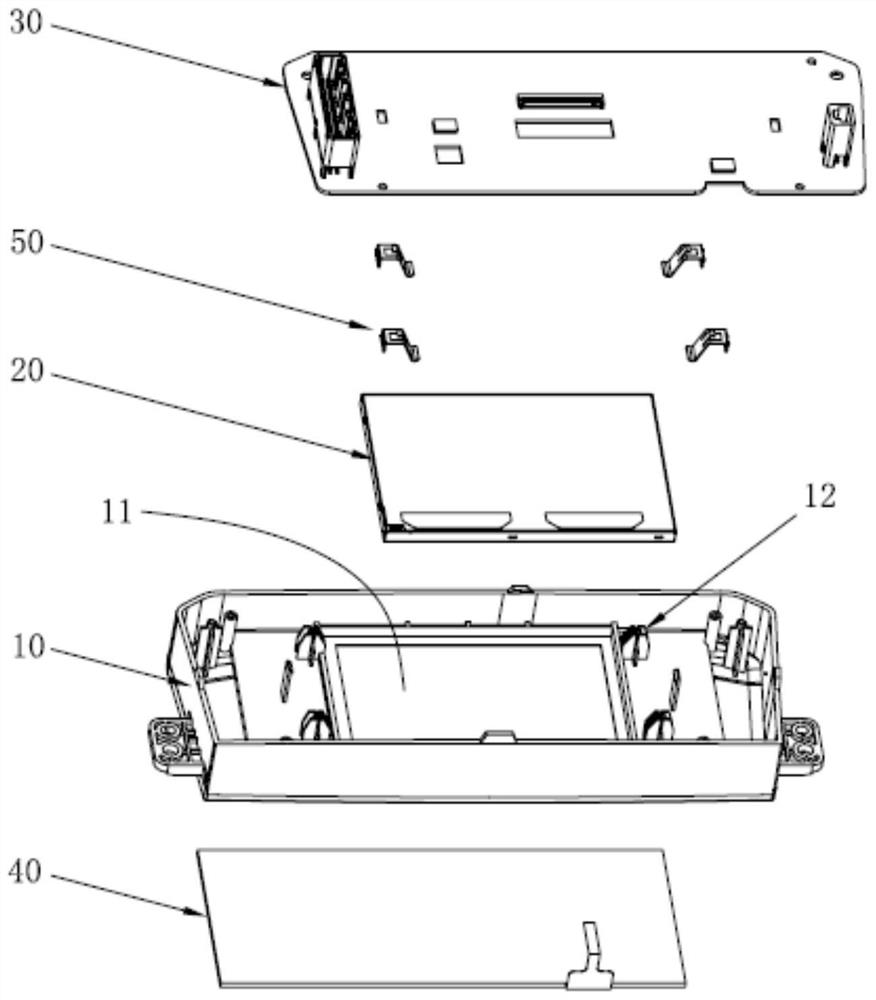

[0020] The elastic screen-pressing bracket of the present invention and the vehicle-mounted electronic device to which it is applied will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0021] An elastic pressure screen bracket, which is in an irregular arch shape, and is integrally made of SUS301 stainless steel, which has the advantages of high temperature strength, fatigue resistance and corrosion resistance.

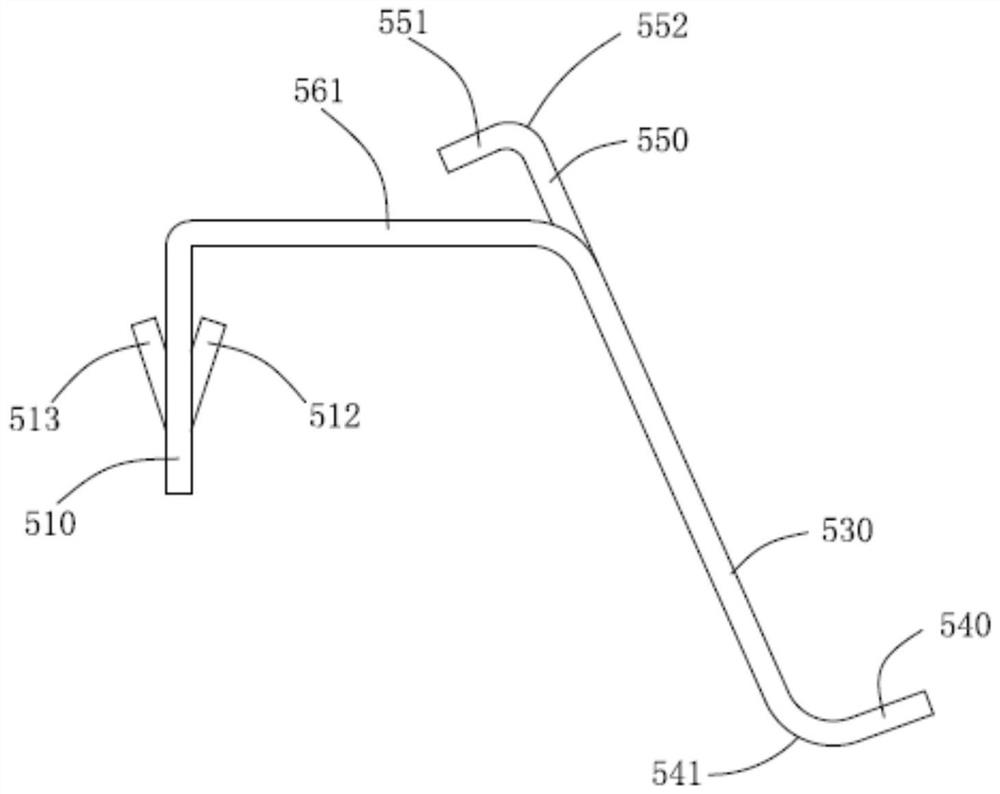

[0022] See also figure 1 and figure 2 , an elastic pressure screen bracket 50, which is sequentially connected by a first plate 510, a second plate 520, two support arms 561, a third plate 530 and a fourth plate 540, the starting end of the first plate 510 Suspended, its tail end is connected with the starting end of the second plate 520, the first plate 510 is connected with the second plate 520 to form a right angle, the supporting arm 561 is in the shape of a sheet bent into an obtuse angle, and the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com